A Calculation Method for Opening Quantity of Inlet Fans on the Top of Brick-fired Tunnel Kiln

A tunnel kiln and blower technology, applied in the field of brick-fired tunnel kilns, can solve problems such as incompatibility, anoxic combustion in roasting zone, and excess carbon monoxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a method for calculating the number of openings of the air inlet fans at the top of a brick-fired tunnel kiln, which is characterized in that it includes the following steps

[0019] S1: Measure the fuel heat F required per hour for a tunnel kiln with a certain section;

[0020] S2: Measure the actual amount of air K required for complete combustion of every 1000 kcal of fuel;

[0021] S3: According to the formula Q=K×F, calculate the air volume Q required per hour for a tunnel kiln with a certain section;

[0022] S4: According to the quantity q of air conveyed by each fan per hour, calculate the number n of the air intake fans turned on, and the formula is n=Q / q.

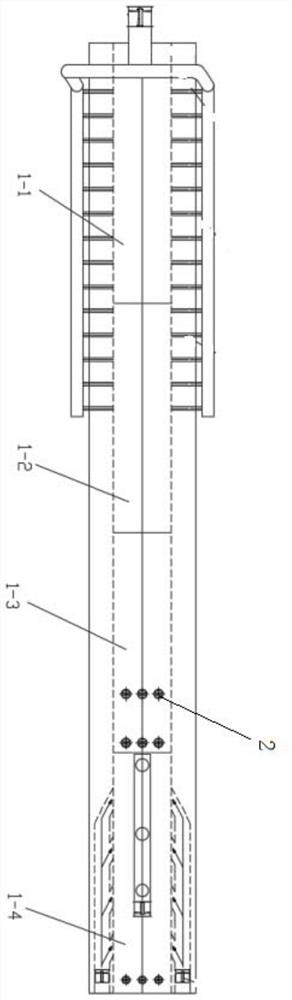

[0023] Such as figure 1 The shown tunnel kiln is divided into brick preheating zone 1-1, high temperature firing zone 1-2, heat preservation zone 1-3 and cooling zone 1-4 from left to right.

[0024] Such as figure 1 Two rows of air inlet fans are installed on the top of the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com