Energy-saving and environment-friendly brick burning tunnel kiln for achieving complete separation of smoke and waste heat

A completely separated, energy-saving and environmentally-friendly technology, applied in the field of tunnel kilns, can solve problems affecting production, excess carbon monoxide, and affecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

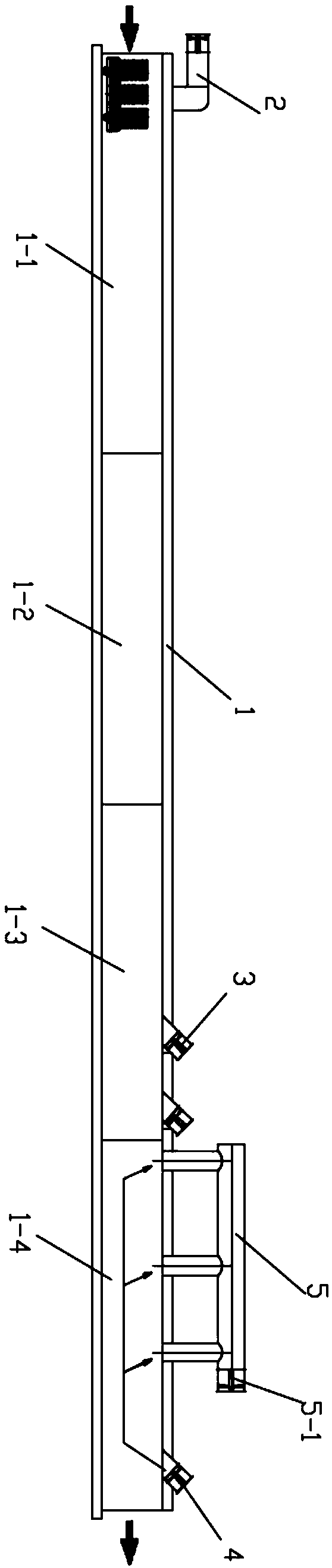

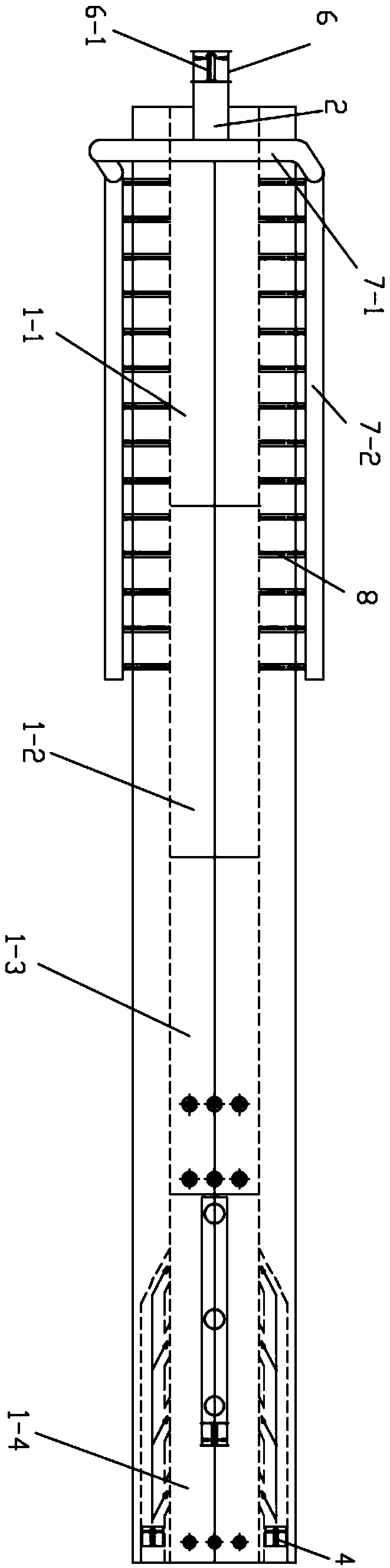

[0016] Such as figure 1 and figure 2 The energy-saving and environment-friendly brick-burning tunnel kiln shown with complete separation of flue gas and waste heat includes a tunnel kiln body 1, and the left and right ends of the tunnel kiln body 1 are respectively provided with car entrances and exits for brick cars to enter and exit. At the car entrance, the tunnel kiln body 1 is divided into brick preheating and heating zone area 1-1, high temperature firing zone area 1-2, heat preservation zone area 1-3 and cooling zone area 1-4 from left to right, The top of the brick preheating zone 1-1 is connected with a flue gas desulfurization device 2, the top of the heat preservation zone 1-3 is provided with a feeding fan 3, and the top of the cooling zone 1-4 is Blowers 4 are installed on the side walls on both sides of the right end, and the top of the cooling belt area 1-4 is connected with an air extraction pipeline 5, and the air extraction pipeline 5 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com