Microwave drying kiln

A technology of microwave drying and microwave heating, which is used in drying solid materials, progressive dryers, heating to dry solid materials, etc., to achieve the effects of eliminating excessively low temperature, good thermal insulation performance and uniform roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

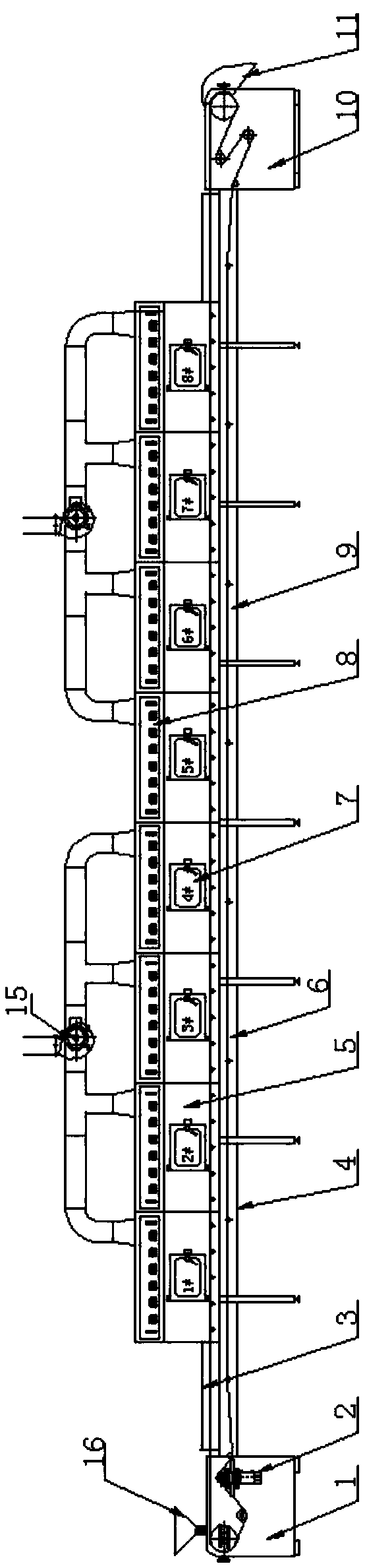

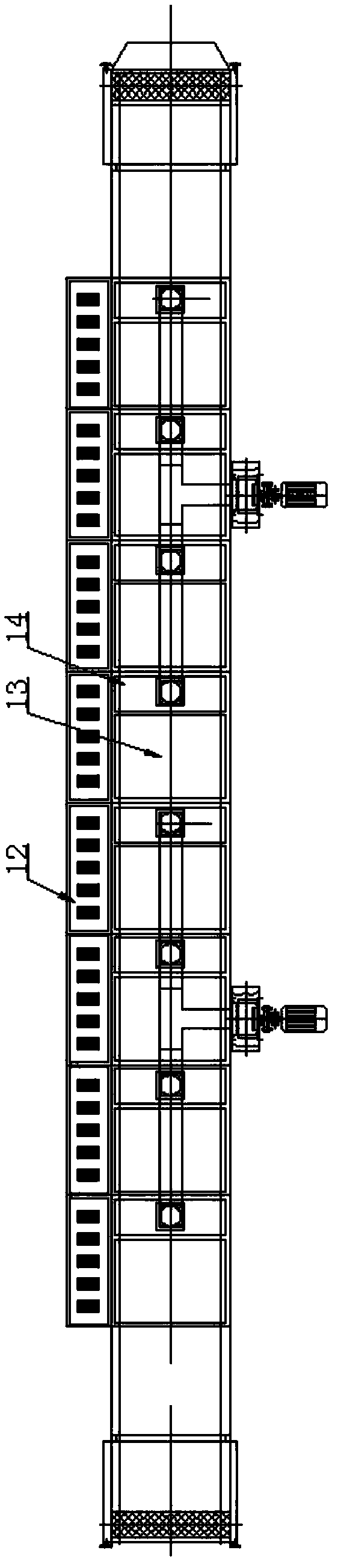

[0015] refer to figure 1 , 2 , a microwave drying kiln, comprising a bridge body bottom plate 6, and a reversing end frame 1 fixedly installed on one side of the bridge body bottom plate 6 and a power end frame 10 fixedly installed on the other side of the bridge body bottom plate 6, the bridge body The overall structure of the bottom plate 6 is a long-span rectangular plate. There are support frames (not shown) fixedly supported on the bottom of the bridge body bottom plate 6. The number of support frames is several, and each support frame is distributed at equal intervals. The bridge body 4 is fixedly installed on the top of the base plate 6, the whole of the bridge body 4 is a rectangular plate, and a through groove body (not shown) is formed in the plate surface of the bridge body 4, and a conveyor belt 9 is placed in the through groove body, and the conveyor belt 9 One end of the bridge body is socketed together with the driving motor inside the reversing end frame 1; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com