Roaster for granular material

A roaster, particle technology, used in applications, food processing, food science, etc., can solve problems such as poor aroma or flavor, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

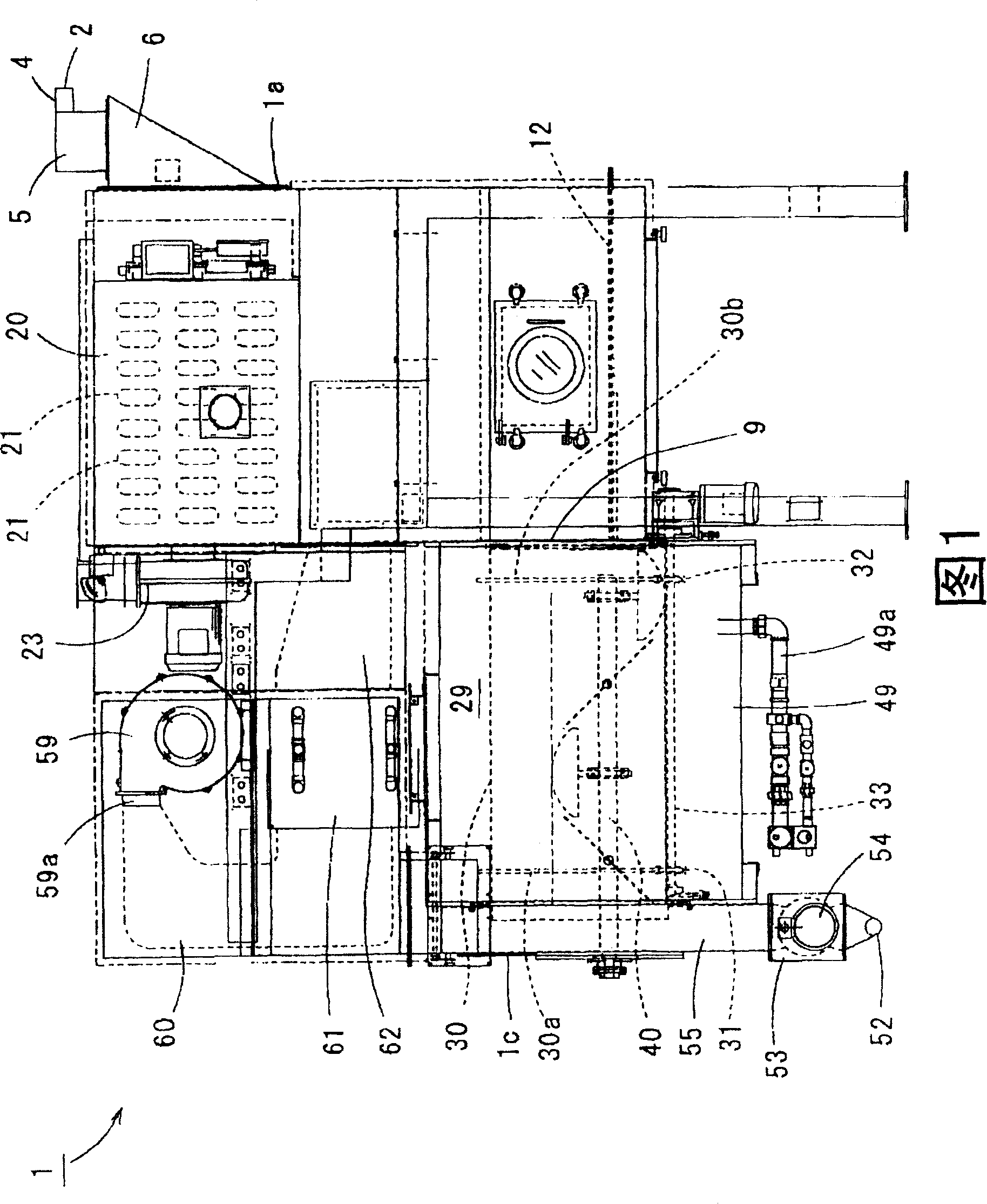

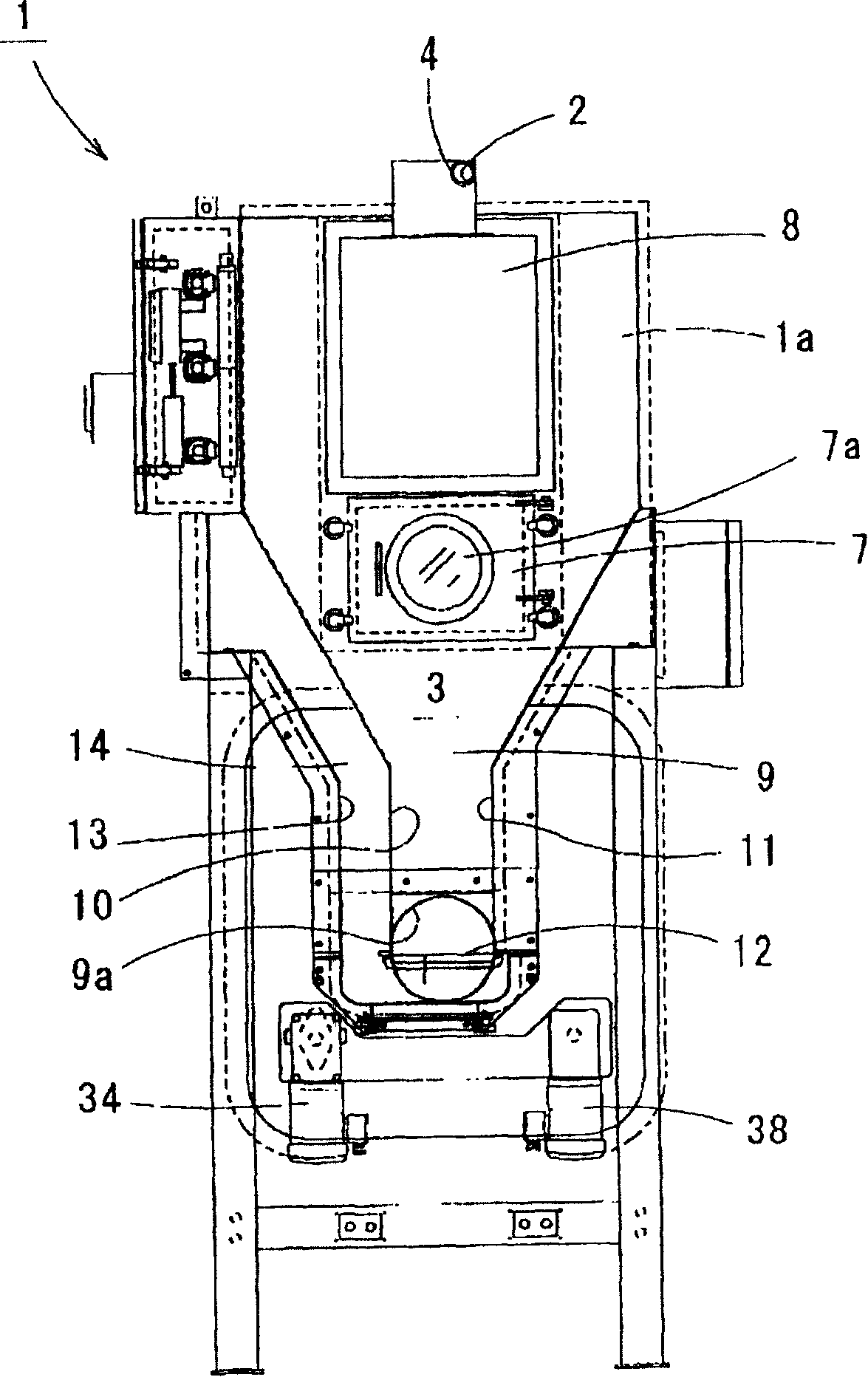

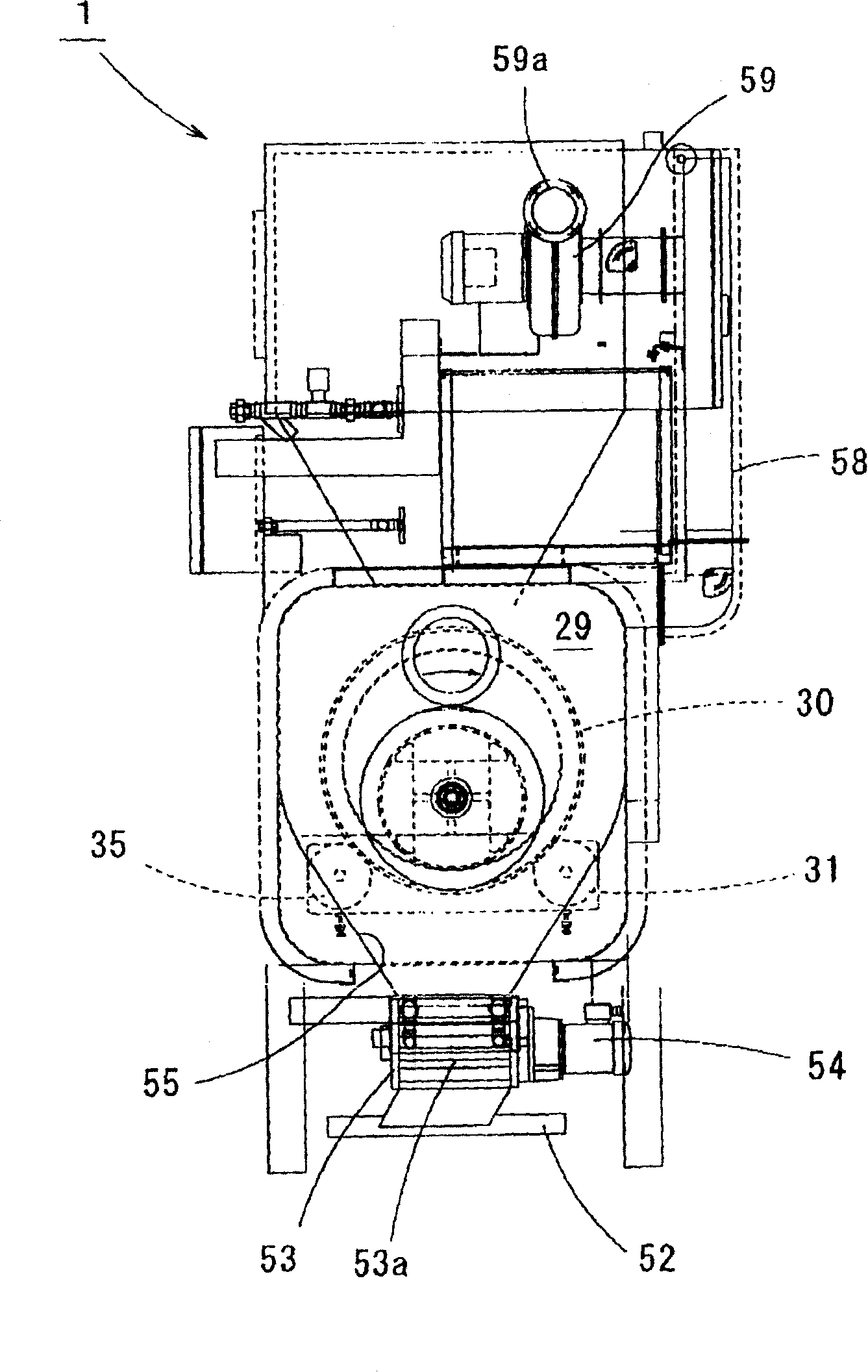

[0039] Next, referring to the drawings, a fine particle calcination furnace according to one embodiment of the present invention will be described in detail. In addition, the roaster for fine particles of the present embodiment is a roaster for coffee beans (hereinafter referred to as a roaster) for roasting coffee beans ground into powder by a mill using the present invention.

[0040] As shown in Figure 1, this roaster 1 is provided with the input port 2 that coffee beans (particles: hereinafter the same) are dropped into, as figure 2 As shown, the inlet 2 communicates with the preheating chamber 3 . The inlet 2 is a portion connected to an end of a hose not shown in the figure, and is a portion into which the coffee beans and compressed air flow. Moreover, the above-mentioned inlet 2 is formed on a connecting member 4 that is formed into a tubular shape and connected to the end of the hose not shown in the above-mentioned figures. As shown in FIG. on the side of body 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com