Method for roasting vanadium-containing stone coal by rotary hearth furnace

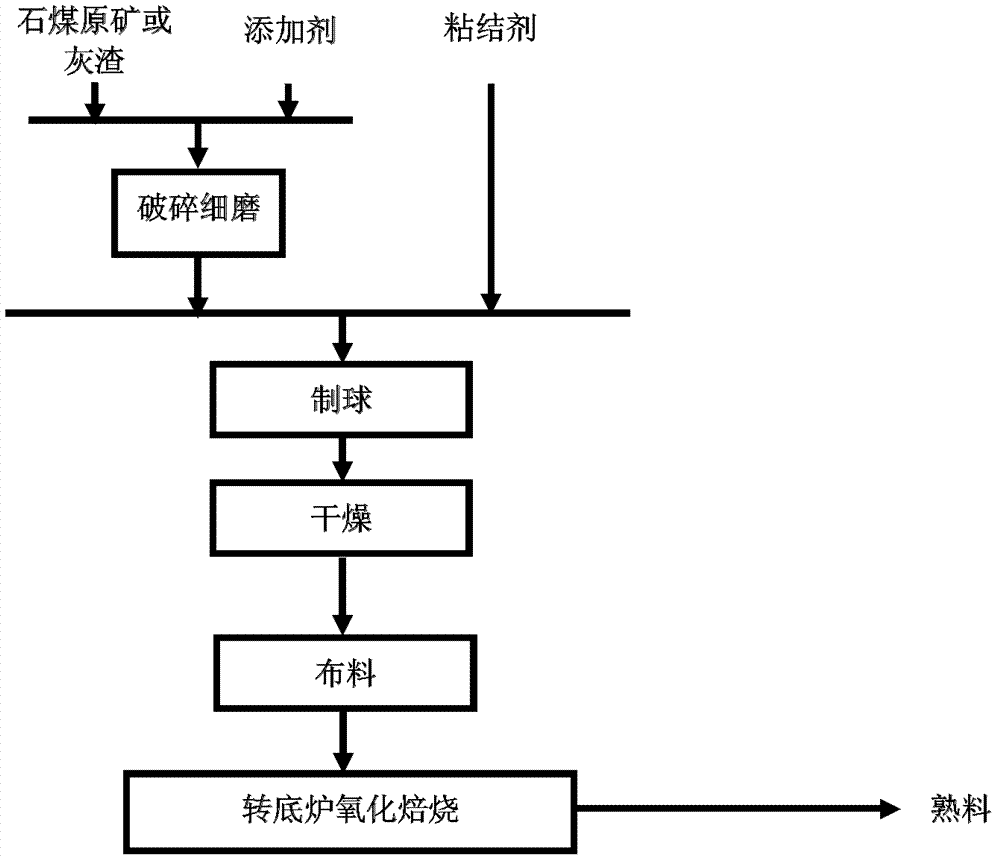

A rotary hearth furnace and roasting technology, which is applied in the field of roasting vanadium-containing stone coal in a rotary hearth furnace, can solve the problems of low conversion rate, low clinker leaching rate, and low equipment output, and achieve high conversion rate, uniform roasting, and leaching high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0032] Stone coal raw ore in a certain place, containing 15% carbon and containing V 2 o 5 1.2%, mix, crush, and finely grind raw stone coal ore and additives, stir and mix evenly according to the ratio of raw ore: additive: binder = 72: 18: 10 by weight, and then use a molding machine to make raw meal balls with a diameter of 20 mm. and dry. The dried raw material balls are distributed into the rotary hearth furnace, and the thickness of the material layer is 40mm. The furnace temperature in the effective roasting area is 800±10°C, and the oxygen content is 15%. The raw meal balls stay in the effective roasting area for 3 hours, and the clinker after being released from the furnace is cooled, broken, and stirred and impregnated in 5% dilute sulfuric acid at room temperature for 6 hours, and the leaching rate is 70%.

specific Embodiment 2

[0033] After the stone coal in a certain place is pre-decarbonized by combustion at 900 °C, the carbon content of 1% and the V content are obtained. 2 o 5 1.3% ash, mix the ash and additives, crush, finely grind, stir and mix evenly according to the ratio of ash by weight: additive: binder=74:15:11, and then use a molding machine to make a raw material with a diameter of 20mm. pellets and dry them. The dried raw material balls are distributed into the rotary hearth furnace, and the thickness of the material layer is 40mm. The furnace temperature in the effective roasting area is 840±10°C, and the oxygen content is 9%. The residence time of the raw meal balls in the effective roasting area is 2.5 hours. The clinker after being released from the furnace is cooled, crushed, stirred and impregnated in 5% dilute sulfuric acid at room temperature for 6 hours, and the leaching rate is 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com