Environment-friendly brick and preparation method thereof

A technology for environmental protection bricks and silt, applied in the field of environmental protection bricks and their preparation, can solve the problems of natural environment damage, negative impact on the ecological environment, etc., and achieve the effects of protecting the environment, increasing building functions, and reducing engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] On the other hand, the present invention provides a kind of preparation method of environmental protection brick, comprises the following steps:

[0038] (1) After the sludge is aged, mix it evenly with cement, fly ash, steel slag and water reducer in a weight ratio, and add water at the same time to make the moisture content of the mixed material 0.5%-2.0% (weight);

[0039] (2) Pressing the mixed material to obtain a blank;

[0040] (3) The green brick is obtained by drying and roasting the green sample.

[0041] The preparation method of the environmental protection brick of the present invention has the advantages of simple production process, easy control, fast construction speed and the like.

[0042] In some preferred embodiments, the preparation method of the environmental protection brick of the present invention comprises the following steps:

[0043] (1) After the sludge is aged, it is evenly mixed with cement, fly ash, steel slag, and water reducing agent ...

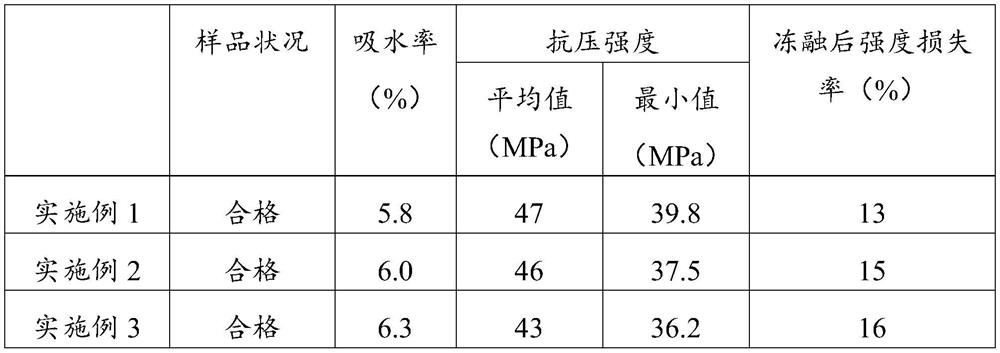

Embodiment 1

[0061] Firstly, the raw coal is transported from the storage shed into the fine crusher and crushed into coal powder smaller than 6mm, the steel slag is filtered to a particle size below 6mm, and the sludge is weathered and aged for 5 days. It is sent to the feed bin by a belt conveyor, and a disc feeder is installed under the feed bin, and the crushed and filtered silt, cement, fly ash and steel slag, water, and water reducing agent are measured and filtered by the disc feeder. Simultaneously feed into a twin-shaft mixer for stirring and mixing, and the moisture content of the mixed material is 1.6% (weight). Among them, by weight, 12 parts of sludge, 30.4 parts of cement, 15 parts of fly ash, 23 parts of steel slag, and 3 parts of water reducing agent. The mixed material is pressed under 8 MPa by a vacuum hydraulic brick extruding unit to obtain a blank sample. The blank sample was dried at 48°C for 40 hours through a tunnel-type drying kiln, and then entered into the tunne...

Embodiment 2

[0063] Firstly, the raw coal is transported from the storage shed into the fine crusher and crushed into coal powder smaller than 6mm, the steel slag is filtered to a particle size below 6mm, and the sludge is weathered and aged for 5 days. It is sent to the feed bin by a belt conveyor, and a disc feeder is installed under the feed bin, and the crushed and filtered silt, cement, fly ash and steel slag, water, and water reducing agent are measured and filtered by the disc feeder. Simultaneously feed into a twin-shaft mixer for stirring and mixing, and the moisture content of the mixed material is 2% (by weight). Among them, by weight, 10 parts of sludge, 32 parts of cement, 30 parts of fly ash, 22.5 parts of steel slag, and 5.5 parts of water reducing agent. The mixed material is pressed under 15MPa by a vacuum hydraulic brick extruder to obtain a blank sample. The blank sample is dried at 50°C for 46 hours through a tunnel-type drying kiln, and then enters the tunnel kiln for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com