A kind of preparation method of molecular sieve membrane support body

A technology of molecular sieve membrane and support, which is applied in the field of preparation of ceramic supports, can solve the problems of powder agglomeration, uneven mud mixing, unfavorable industrial production, etc., and achieve uniform performance distribution, wide application range, simple and economical process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

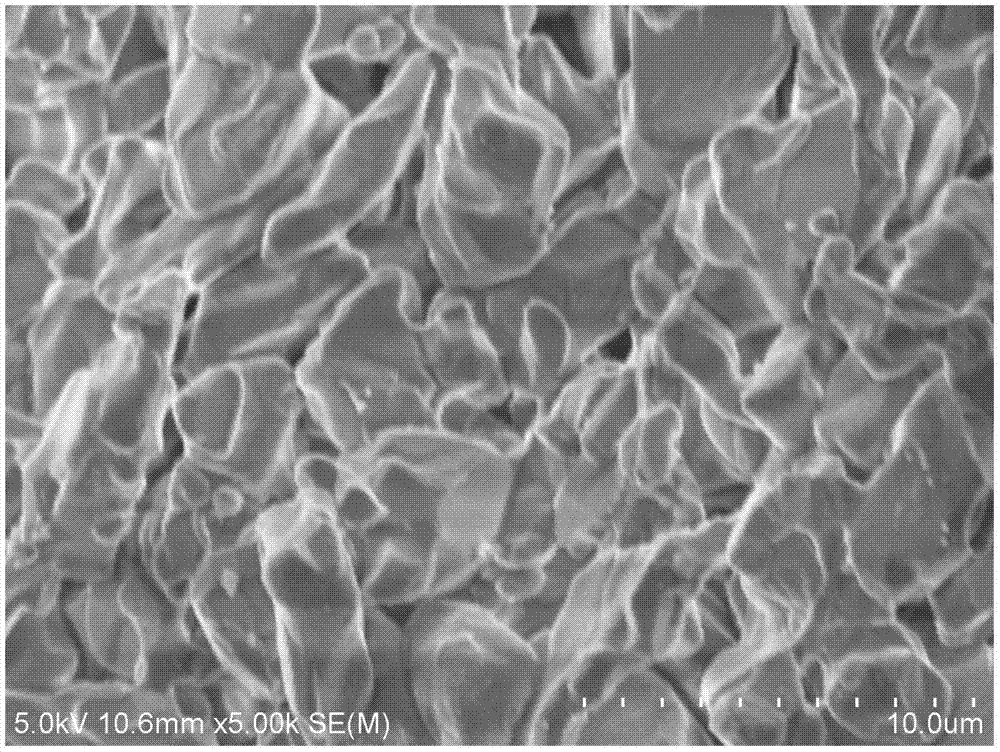

Image

Examples

Embodiment 1

[0033] 1) Take 10kg of mullite fine powder with an average particle size of 6μm as ceramic powder aggregate, add 500g of starch with a particle size of less than 5μm, and mix well;

[0034] 2) Add 500g of nano-alumina dispersion with a content of 40wt%, 500g of hydroxypropyl methylcellulose, 1kg of polyethylene glycol, 1kg of Glycerin, stir evenly, stale for 12 hours to make mud;

[0035] 3) The mud material is subjected to vacuum refining and aging for 48 hours, and then extruded to obtain a single-tube porous molecular sieve membrane support wet billet;

[0036] 4) Place the wet billet at 30°C and 80% relative humidity to dry naturally for 48 hours, and dry to obtain a green billet;

[0037] 5) Hang the green body in a sintering furnace, sinter at 1500°C for 4 hours, and then cool naturally to obtain a molecular sieve membrane support.

[0038] The obtained support was characterized, with an average pore size of 1.3 μm and a porosity of 35%. Boiling in 10% sodium hydroxid...

Embodiment 2

[0040] 1) Take 8kg of α-alumina with an average particle size of 5μm and 2kg of silica with an average particle size of 3μm as ceramic powder aggregate, add 300g of activated carbon with a particle size of less than 3μm, and mix well;

[0041] 2) Add 400g of aluminum sol with a content of 40%, 500g of paraffin, 1kg of polyvinyl alcohol, and 1kg of tung oil to the mixed powder obtained in step 1) in sequence by spraying while stirring, stir evenly, and stale for 24 hours to make mud material;

[0042] 3) The mud material is subjected to vacuum refining and aging for 24 hours, and then extruded to obtain a four-channel porous molecular sieve membrane support body wet billet;

[0043] 4) Place the wet billet at 25°C and 60% relative humidity to dry naturally for 56 hours, and dry to obtain a green billet;

[0044] 5) Hang the green body in a sintering furnace, sinter at 1600°C for 6 hours, and then cool naturally to obtain a molecular sieve membrane support.

[0045] The obtain...

Embodiment 3

[0047] 1) Use 10kg of α-alumina powder with an average particle size of 2μm as ceramic powder aggregate, add 600g of activated carbon with a particle size of less than 1μm, and mix well;

[0048]2) While stirring, add 400g of nano-titanium oxide dispersion with a content of 40%, 500g of paraffin, 800g of polyethylene glycol, and 1.2kg of glycerin to the mixed powder obtained in step 1) in turn by spraying, and stir evenly. Prepare mud in 24 hours;

[0049] 3) The mud material is subjected to vacuum refining and aging for 36 hours, and then extruded to obtain a four-channel porous molecular sieve membrane support body wet billet;

[0050] 4) Place the wet billet at 35°C and 70% relative humidity to dry naturally for 36 hours, and dry to obtain a green billet;

[0051] 5) Hang the green body in a sintering furnace, sinter at 1250°C for 2 hours, and then cool naturally to obtain a molecular sieve membrane support.

[0052] The obtained support was characterized, with an average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com