Method for preparing ceramic membrane support body from purified water sludge and prepared ceramic membrane support body

A ceramic membrane support, ceramic membrane technology, applied in ceramic material production, permeation/dialysis water/sewage treatment, application, etc., can solve problems such as high disposal costs, reduce environmental pressure, high removal rate, small pore size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

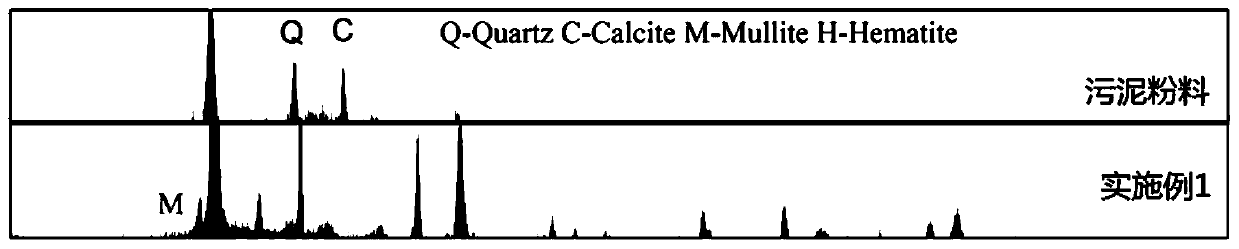

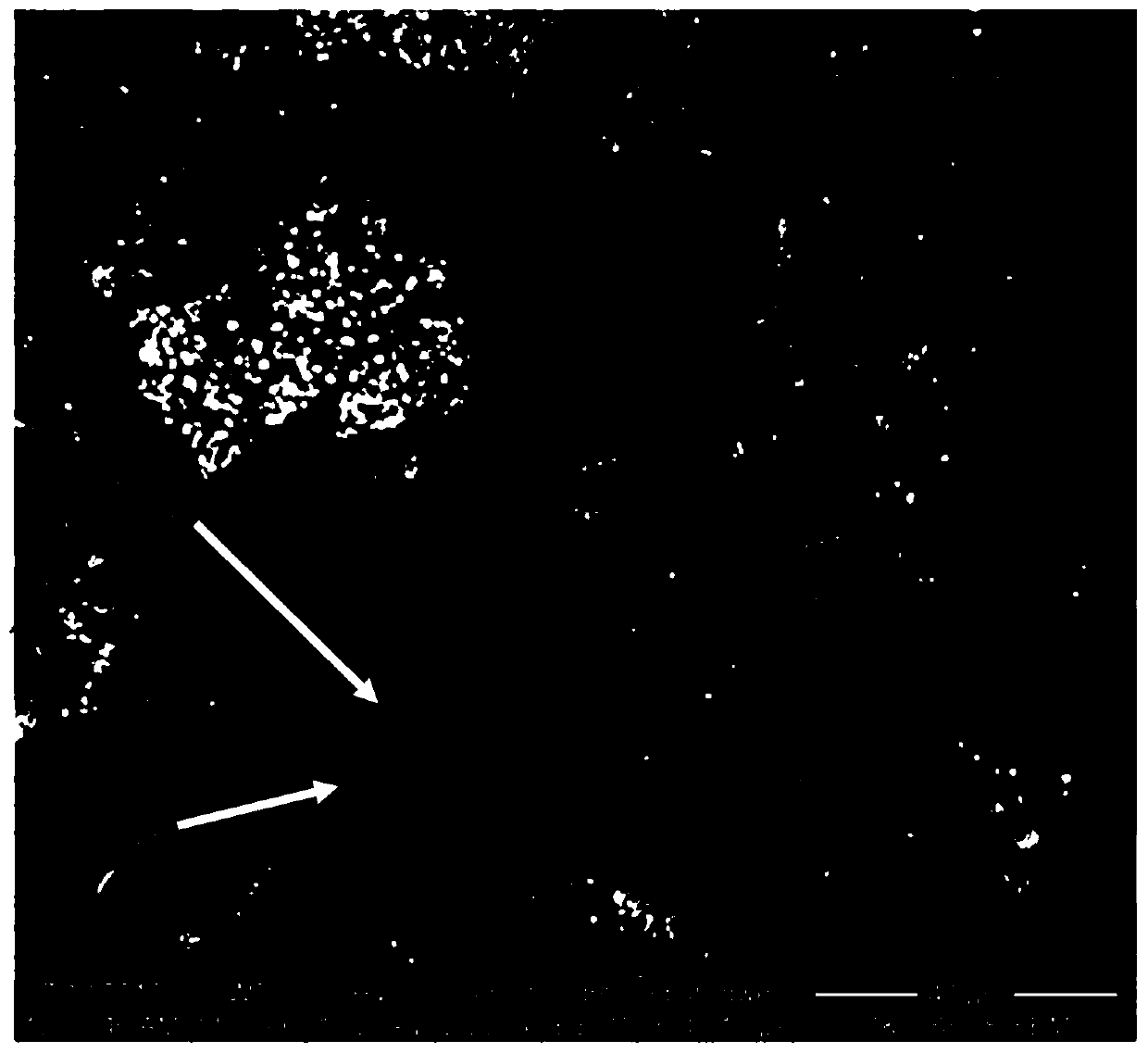

[0074] Embodiment 1 Preparation of Tubular Ceramic Membrane Support Body

[0075] 1. Preparation of sludge powder

[0076] The water purification sludge is dried at 100±5°C until the moisture content reaches 5%, and then pulverized by a pulverizer, and the pulverized material is passed through a 170-240 mesh sieve to obtain sludge powder , the particle size of sludge powder is 60-80μm;

[0077] 2. Preparation of sludge block material

[0078] Spray water into the sludge powder to make the moisture content of the sludge powder reach 50%, and then put it in a mud refining machine (Dabin company, model Potfan 3-b), and put it under normal temperature (15-30°C) and normal pressure Carry out mud treatment.

[0079] Mud refining can remove the air and impurities in the mud, making the raw materials more dense and uniform in temperature to facilitate shaping. If there are air bubbles in the green body, the air will expand due to heat during firing, causing the ceramic film to def...

Embodiment 2

[0093] Embodiment 2 Preparation of Tubular Ceramic Membrane Support Body

[0094] 1. Preparation of sludge powder

[0095] The water purification sludge is dried at 100±5°C until the moisture content reaches 8%, and then pulverized by a pulverizer, and the pulverized material is passed through a 170-240 mesh sieve to obtain sludge powder , the particle size of sludge powder is 60-80μm;

[0096] 2. Preparation of sludge block material

[0097] Spray water into the sludge powder to make the moisture content of the sludge powder reach 40%, and then place it in a vacuum mud refining machine for mud refining;

[0098] After 3 hours of sludge refining treatment, the sludge was divided into sealed bags, sealed and stored at room temperature (20-25°C), and aged for 24 hours to obtain sludge refining sludge blocks;

[0099] 3. Compression molding treatment

[0100] 3-1) Evenly fill the sludge refining mud block material (100-150g) into the mold, and use a hydraulic press for pressi...

Embodiment 3

[0108] Example 3 Preparation of Tubular Ceramic Membrane Support

[0109] 1. Preparation of sludge powder

[0110] Dry the water purification sludge at 100±5°C until the moisture content reaches 6%, then use a pulverizer for pulverization treatment, and the pulverized material is passed through a 170-240 mesh sieve to obtain sludge powder , the particle size of sludge powder is 60-80μm;

[0111] 2. Preparation of sludge block material

[0112] Spray water into the sludge powder to make the moisture content of the sludge powder reach 50%, and then place it in a vacuum mud refining machine for mud refining;

[0113] After sludge refining treatment for 1 hour, separate the sludge into sealed bags, store it sealed at room temperature (20-25°C), and perform aging treatment for 36 hours to obtain sludge refining sludge block;

[0114] 3. Molding treatment

[0115] 3-1) Evenly fill the sludge refining mud block material (100-150g) into the mold, and use a hydraulic press for pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com