Recycled cement-based material based on 3D printing and preparation method thereof

A recycled cement and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of long construction period, high cost, and ineffective use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

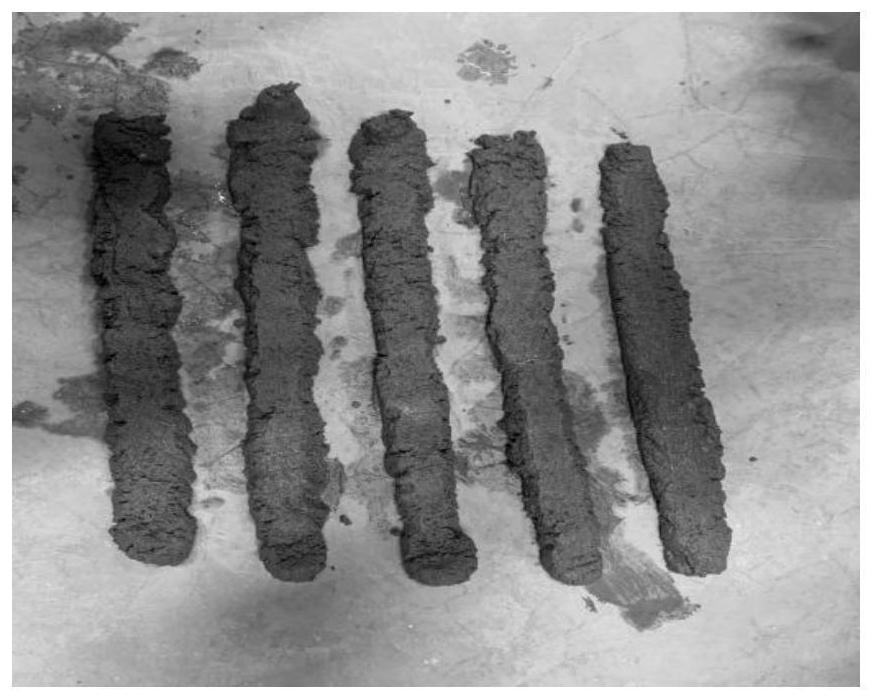

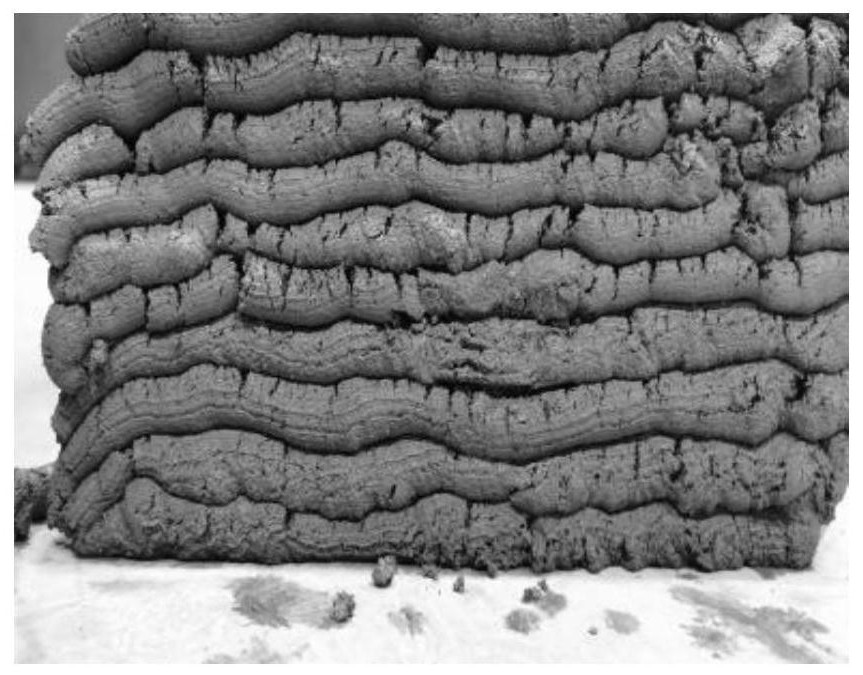

Image

Examples

preparation example Construction

[0036] In addition, an embodiment of the present invention also provides a method for preparing recycled cement-based materials based on 3D printing, including the following steps:

[0037] Place the cement, the ceramic powder, the fly ash, the graphite tailings, the river sand, the thickener and the basalt fiber in a heating and stirring device at a stirring speed of 1500r / Stirring under the condition of min-1800r / min for 12min-15min to obtain the first mixture;

[0038] Mixing the alkaline water agent and the water uniformly in proportion to obtain a second mixture;

[0039] Adding a second mixture accounting for 1 / 2 of the volume of the second mixture to the first mixture under stirring, and continuing to stir for 3min-10min to obtain a third mixture;

[0040] Under the condition of stirring, the rest of the second mixture is added, and the stirring is continued for 3 minutes to 10 minutes to obtain a recycled cement-based material.

Embodiment 1

[0049] A preparation method of recycled cement-based material based on 3D printing is as follows:

[0050] Place 1.0kg of cement, 0.29kg of ceramic powder, 0.14kg of fly ash, 0.57kg of graphite tailings, 1.7kg of river sand, 0.017kg of industrial grade xanthan gum and 0.05kg of basalt fiber into a heating and stirring device. Stirring under the condition of 1500r / min for 12min to obtain the first mixture;

[0051] Mix 0.008kg polycarboxylate water reducer and 0.56kg water uniformly in proportion to obtain the second mixture;

[0052] Adding a second mixture accounting for 1 / 2 of the volume of the second mixture to the first mixture under stirring, and continuing to stir for 3 minutes to obtain a third mixture;

[0053] Under the condition of stirring, the rest of the second mixture was added, and the stirring was continued for 3 minutes to obtain a regenerated cement-based material.

Embodiment 2

[0055] A preparation method of recycled cement-based material based on 3D printing is as follows:

[0056] 1.0kg cement, 0.25kg ceramic powder, 0.08kg fly ash, 0.25kg graphite tailings, 1.2kg river sand, 0.008kg industrial grade xanthan gum and 0.003kg basalt fiber were placed in the heating and stirring device. Stirring under the condition of 1800r / min for 15min to obtain the first mixture;

[0057] Mix 0.005kg of polycarboxylate water reducer and 0.50kg of water uniformly in proportion to obtain the second mixture;

[0058] Adding a second mixture accounting for 1 / 2 of the volume of the second mixture to the first mixture under stirring, and continuing to stir for 10 minutes to obtain a third mixture;

[0059] Under the condition of stirring, the rest of the second mixture was added, and the stirring was continued for 10 minutes to obtain a recycled cement-based material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com