Drum shape container for body fluid treatment device and body liquid treatment device

A processor and body fluid technology, applied in the direction of dialysis systems, etc., can solve the problems of improvement and unfinished strength, and achieve the effect of improving assembly process and forming production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

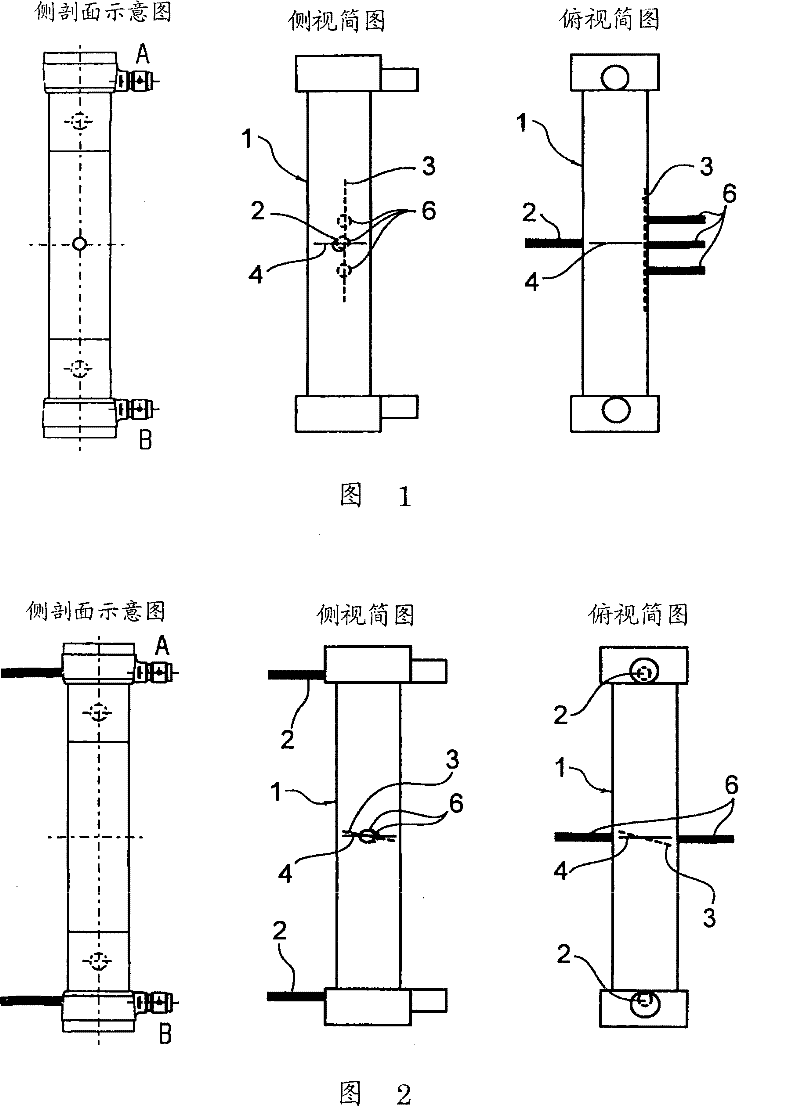

[0083] like figure 1 As shown in , a gate 2 is provided in the center of the circumferential surface of the cylindrical container 1, and a styrene-butadiene copolymer resin is injection-molded by a mold to obtain a total length of 280 mm, an outer diameter (tube part) of 40 mm, and a wall thickness of 2 mm. In the cylindrical container for body fluid treatment, three air exhaust pipes are installed at approximately equal intervals as the gas discharge part on the outer surface side of the mold that abuts on the weld line 3 that appears on the cylindrical container 1. pin 6.

[0084] As a result of the impact test A, it was confirmed that the impact strength of the part not on the weld line was 20kg·cm / cm, while the impact strength on the weld line was 12kg·cm / cm, maintaining 60% of the impact resistance strength. The results are shown in Table 1.

Embodiment 2

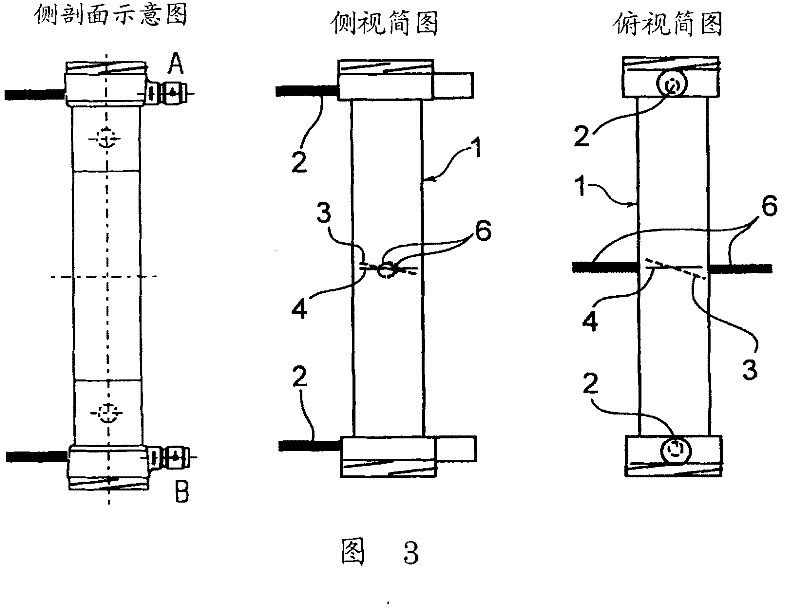

[0086] like figure 2 As shown in , two gates 2 are provided near both ends of the circumferential surface of the cylindrical container 1, and a styrene-butadiene copolymer resin is injection-molded using a mold to obtain a total length of 280mm, an outer diameter (tube part) of 40mm, In the cylindrical container for body fluid treatment with a wall thickness of 2mm, in the mold, the outer surface side of the mold that abuts on the welded line 3 that appears on the cylindrical container 1 is mounted on the circumferential surface facing each other. The root is the exhaust needle 6 as the gas discharge part.

[0087] As a result of the impact test A, it was confirmed that the impact resistance of the part not on the weld line was 20kg·cm / cm, while the impact resistance on the weld line was 11kg·cm / cm, maintaining 55% of the impact resistance strength. The results are shown in Table 1.

Embodiment 3

[0089] like image 3 As shown in , except that the structure of the mold for obtaining the cylindrical container 1 with threads applied to both ends was used, the same mold as in Example 2 was used to install the gate and the exhaust needle, and the acrylonitrile resin was injection-molded to obtain a total length of 280 mm. , A cylindrical container for body fluid treatment with an outer diameter (cylindrical portion) of 40 mm and a wall thickness of 2 mm.

[0090] As a result of the impact test A, it was confirmed that the impact resistance of the part not on the weld line was 16kg·cm / cm, while the impact resistance on the weld line was 10kg·cm / cm, maintaining 63% of the impact resistance strength. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com