Flaring-type rotary kiln for vanadium extraction of stone coal

A rotary kiln and flaring technology, applied in the field of rotary kiln, can solve problems such as difficult preheating capacity and heating capacity, complex heat transfer process, and affecting roasting quality, so as to improve preheating and heating capacity, uniform temperature distribution, The effect of sufficient roasting reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

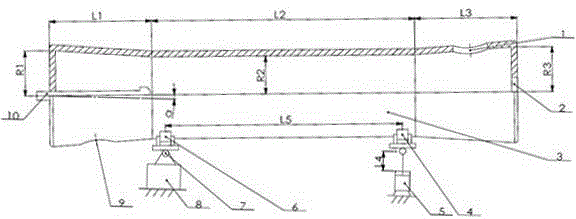

[0023] A flared rotary kiln for vanadium extraction from stone coal. The structure of the rotary kiln is as follows figure 1 Shown: including kiln body 3 , sleeve burner 10 , first supporting roller group 6 and second supporting roller group 4 . The kiln body 3 is composed of a left flared section kiln body, a straight barrel section kiln body and a right flared section kiln body. The left flared section kiln body, the straight barrel section kiln body and the right flared section kiln body are coaxial overall structures. The kiln body of the left flaring section is in the shape of a truncated cone, the kiln body of the straight barrel section is of equal diameter, and the kiln body of the right flaring section is in the shape of a truncated cone.

[0024] A material outlet 9 is provided near the left end of the kiln body in the left flaring section, and a material inlet 1 is provided near the right end of the kiln body in the right flaring section. The projection is arrange...

Embodiment 2

[0030] A flared rotary kiln for vanadium extraction from stone coal. Except following technical parameter, all the other are with embodiment 1.

[0031] The center distance L between the first supporting wheel set 6 and the second supporting wheel set 4 5 =(0.75~0.80)L 2 ;

[0032] The working stroke of the hydraulic cylinder 5 is L 4 =(0.05~0.10)L 5 ;

[0033] The ratio of the maximum diameter to the minimum diameter of the kiln body in the left flaring section is 2R 1 :2R 2 =(1.15~1.20):1;

[0034] The ratio of the length to the maximum diameter of the kiln body in the left flaring section is L 1 :2R 1 =(1.0~1.1):1;

[0035] The ratio of the length of the straight section kiln body to the diameter of the straight section kiln body is L 2 :2R 2 =(6~7):1;

[0036] The ratio of the maximum diameter to the minimum diameter of the kiln body in the right flaring section is 2R 3 :2R 2 =(1.15~1.20):1;

[0037] The ratio of the length to the maximum diameter of the ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com