A microwave high-temperature roasting reduction method for nickel-containing sludge

A high-temperature roasting and weight reduction technology, which is used in pyrolysis treatment of sludge, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of effective utilization of high-temperature gas without considering the dielectric characteristics of the medium, and achieve the elimination of small leakage, The effect of increasing heating efficiency and improving high-temperature roasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

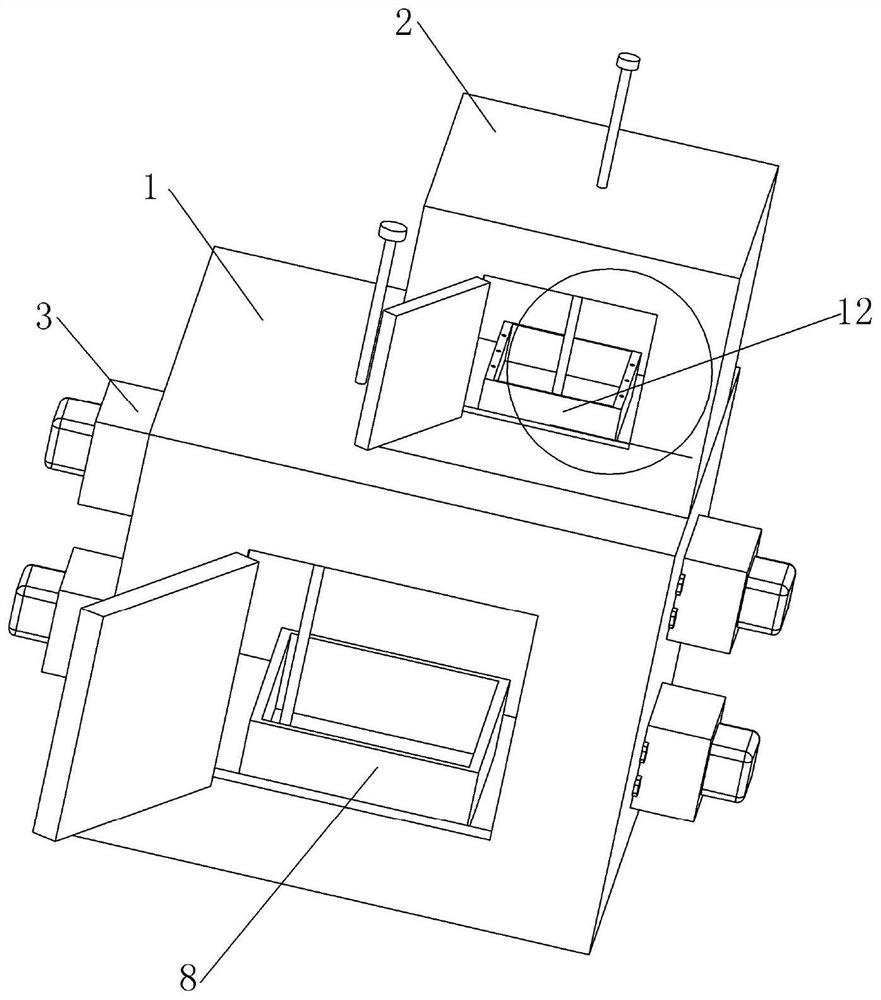

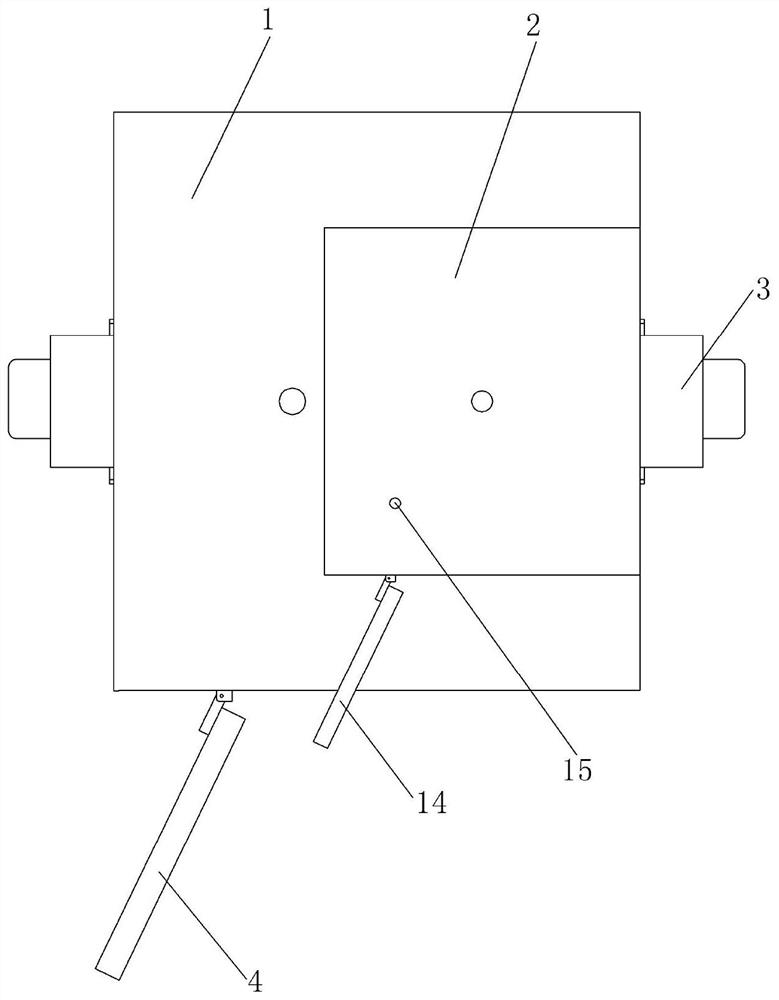

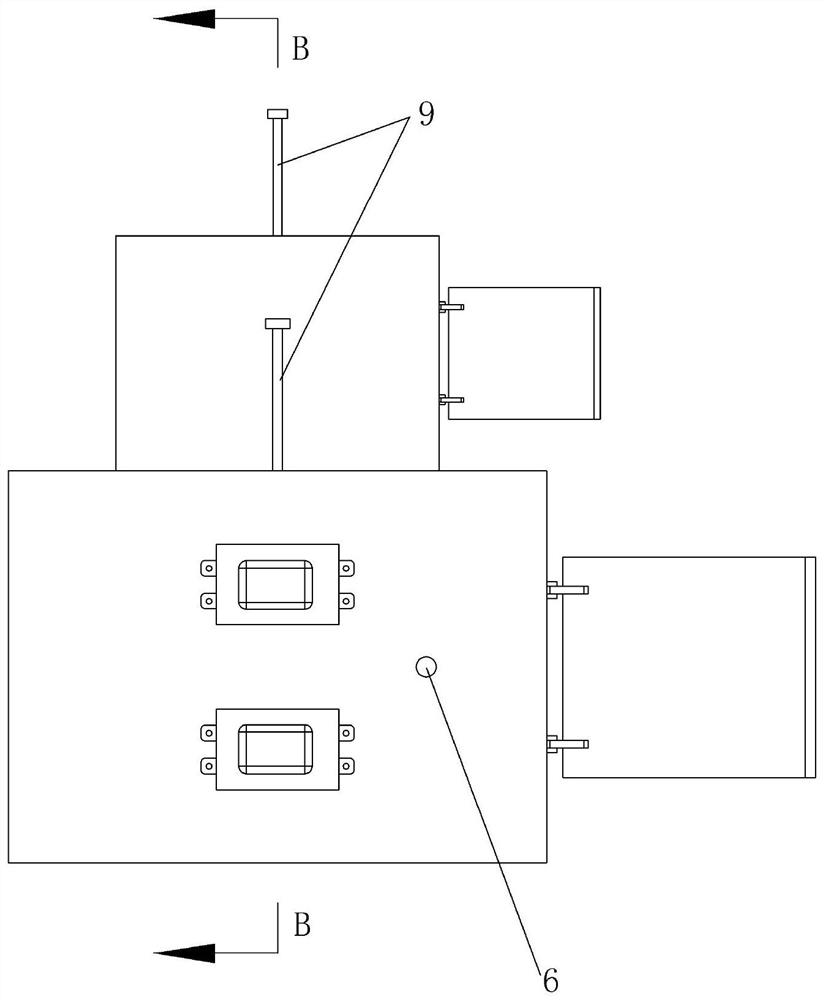

[0035] A nickel-containing sludge reduction dual-cavity microwave high-temperature roasting device, such as Figure 1-6 As shown, it includes a microwave heating furnace 1 and a preheating furnace 2, and the nickel-containing sludge reduction dual-cavity microwave high-temperature roasting device includes a microwave heating furnace 1 and a preheating furnace 2, and the microwave heating furnace has two symmetrical A symmetrical microwave generating device 3 is arranged on the side furnace wall, and the microwave generating device heats the nickel-containing sludge in the heating furnace, and a furnace wall 7 adjacent to the microwave generating device on one side is provided with a heating furnace door 4, The door is used to put in and take out the nickel-containing sludge. The inside of the microwave heating furnace is a heating chamber 5, and the furnace wall on one side of the microwave heating furnace is provided with an air inlet 6 through to the inside of the heating cha...

Embodiment 2

[0042] A microwave high-temperature roasting reduction method for nickel-containing sludge comprises the following steps:

[0043] (1) crush the nickel-containing sludge with a moisture content of 8%, and set aside;

[0044] (2) Open the heating furnace door 4 on the wall 7 of the microwave heating furnace 1, and the preheating door 14 on the preheating furnace wall 16 of the preheating furnace 2, and place the broken nickel-containing sludge in the microwave heating furnace respectively. Inside the material bin 8 of the heating chamber 5 of the furnace 1 and the hollow material bin 12 of the preheating chamber 10 of the preheating furnace 2;

[0045] (3) Open the microwave generating device 3 of the microwave heating furnace, adjust the microwave power 1500W, and feed the dry air with a flow rate of 200ml / min into the heating cavity to heat and roast the nickel-containing sludge by the microwave heating furnace inlet 6 simultaneously;

[0046] (4) Heating the nickel-containi...

Embodiment 3

[0052] A microwave high-temperature roasting reduction method for nickel-containing sludge comprises the following steps:

[0053] (1) crush the nickel-containing sludge with a moisture content of 8%, and set aside;

[0054] (2) Open the heating furnace door 4 on the wall 7 of the microwave heating furnace 1, and the preheating door 14 on the preheating furnace wall 16 of the preheating furnace 2, and place the broken nickel-containing sludge in the microwave heating furnace respectively. Inside the material bin 8 of the heating chamber 5 of the furnace 1 and the hollow material bin 12 of the preheating chamber 10 of the preheating furnace 2;

[0055] (3) Open the microwave generating device 3 of the microwave heating furnace, adjust the microwave power 1500W, and feed the dry air with a flow rate of 50ml / min into the heating cavity to heat and roast the nickel-containing sludge by the microwave heating furnace inlet 6 simultaneously;

[0056] (4) Heating the nickel-containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com