Treatment method for sulfur-containing leaching residues, and application thereof

A treatment method and leaching slag technology, which is applied in the field of metallurgy, can solve problems such as insufficient SO2 concentration, unfavorable recovery of valuable metals in leaching slag, and insufficient waste heat recovery efficiency, so as to achieve good energy saving effects, facilitate SO2 recovery, and improve waste heat recovery efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a treatment method for sulfur-containing leaching slag, and the composition of the sulfur-containing leaching slag to be treated is shown in the following table:

[0058] composition

Zn

Pb

S

Fe

Ag(g / t)

As

wt%

17.15

1.14

57.40

5.25

0.17

0.02

[0059] The processing method is as follows:

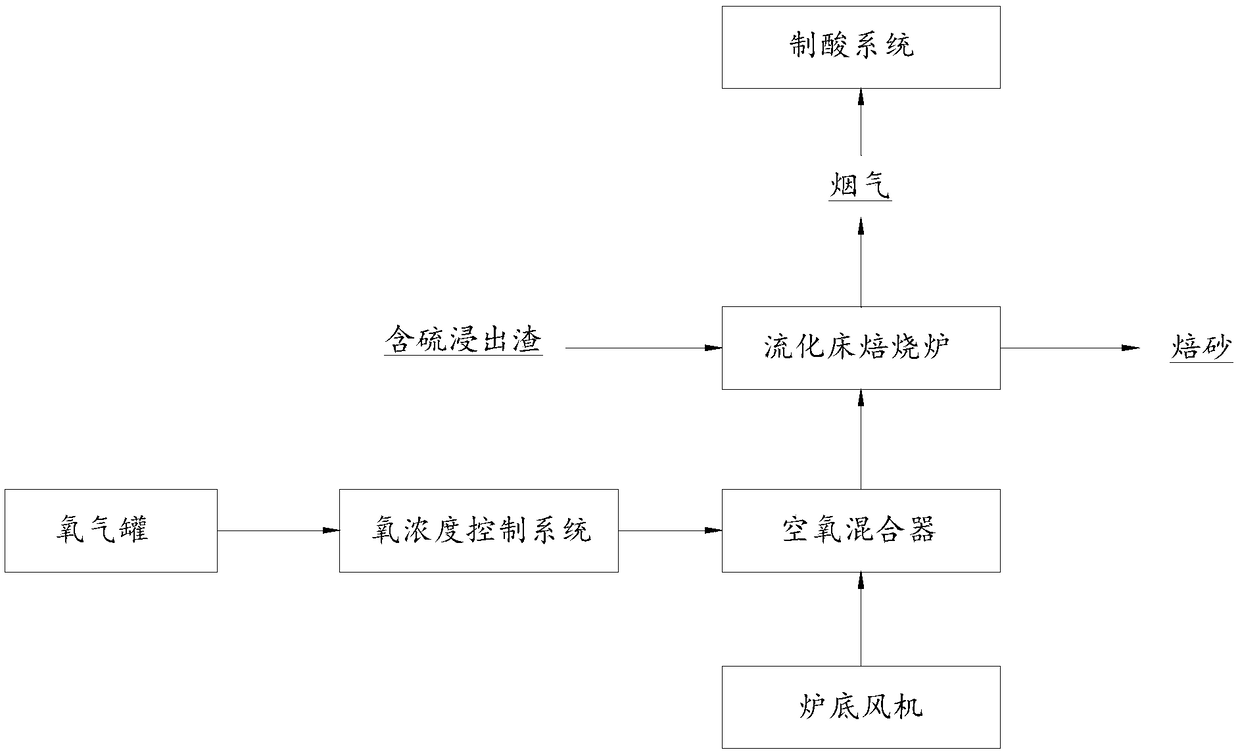

[0060] The oxygen in the oxygen tank is regulated by the oxygen concentration control system and enters the air-oxygen mixer. The air-oxygen mixer mixes air and oxygen to form a mixed gas. The working pressure of the oxygen tank is 1.0MPa.

[0061] The oxygen concentration control system of this embodiment includes a flow meter for detecting the flow of oxygen, a pressure gauge for detecting the pressure of oxygen, a pressure reducing valve for reducing the pressure of oxygen, and a regulating valve for adjusting the flow of oxygen. After the oxygen is decompressed by the pressure reducing valve, the...

Embodiment 2

[0069] This embodiment provides a treatment method for sulfur-containing leaching slag, and the composition of the sulfur-containing leaching slag to be treated is shown in the following table:

[0070] composition

Zn

Pb

S

Fe

Ag(g / t)

As

wt%

17.15

1.14

57.40

5.25

0.17

0.02

[0071] The processing method is as follows:

[0072] The oxygen in the oxygen tank is adjusted by the oxygen concentration control system and then enters the air-oxygen mixer. The air-oxygen mixer mixes air and oxygen to form a mixed gas. The working pressure of the oxygen tank is 1.3MPa.

[0073] The oxygen concentration control system of this embodiment includes a flow meter for detecting the flow of oxygen, a pressure gauge for detecting the pressure of oxygen, a pressure reducing valve for reducing the pressure of oxygen, and a regulating valve for adjusting the flow of oxygen. After the oxygen is decompressed by the pressure reducing valve,...

Embodiment 3

[0081] This embodiment provides a treatment method for sulfur-containing leaching slag, and the composition of the sulfur-containing leaching slag to be treated is shown in the following table:

[0082] composition

Zn

Pb

S

Fe

Ag(g / t)

As

wt%

17.15

1.14

57.40

5.25

0.17

0.02

[0083] The processing method is as follows:

[0084] The oxygen in the oxygen tank is adjusted by the oxygen concentration control system and then enters the air-oxygen mixer. The air-oxygen mixer mixes air and oxygen to form a mixed gas. The working pressure of the oxygen tank is 1.6MPa.

[0085] The oxygen concentration control system of this embodiment includes a flow meter for detecting the flow of oxygen, a pressure gauge for detecting the pressure of oxygen, a pressure reducing valve for reducing the pressure of oxygen, and a regulating valve for adjusting the flow of oxygen. After the oxygen is decompressed by the pressure reducing valve,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com