Method for recycling waste foundry sand through compound roasting device

A technology of foundry waste sand and equipment pairing, which is applied in the direction of casting molding equipment, metal processing equipment, lighting and heating equipment, etc. It can solve the problems of high heat loss, poor environmental protection effect, insufficient combustion of foundry waste sand and exhaust gas, etc. To achieve the effect of improving the demoulding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

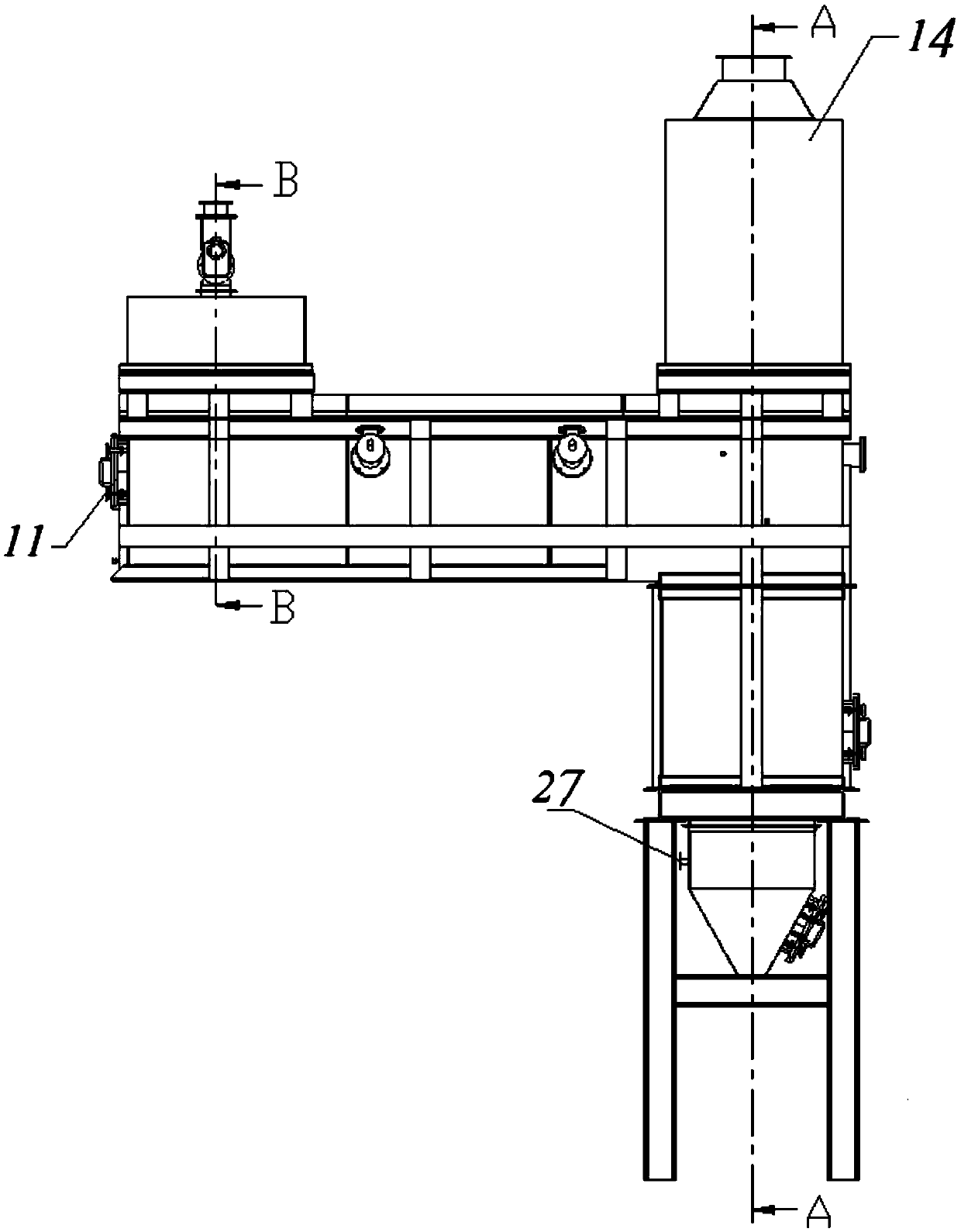

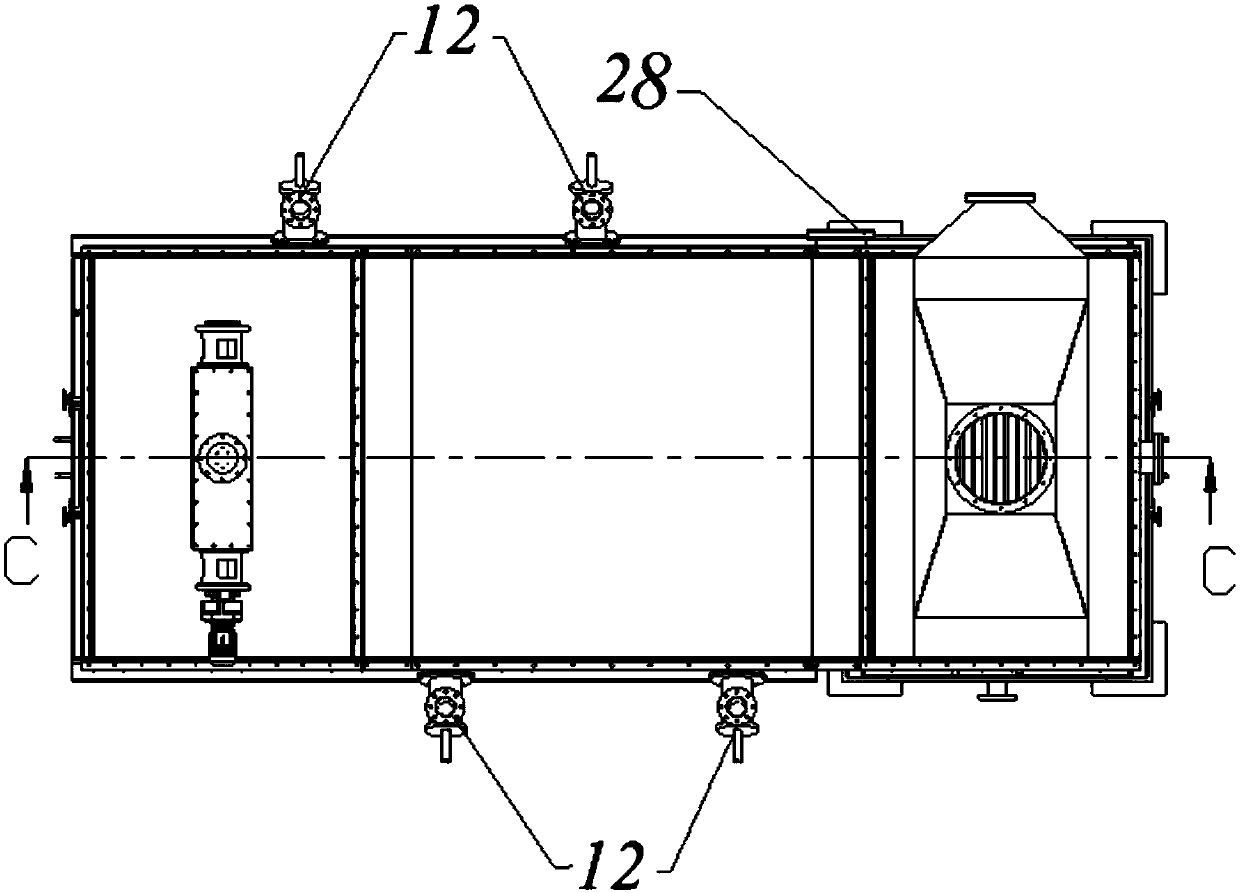

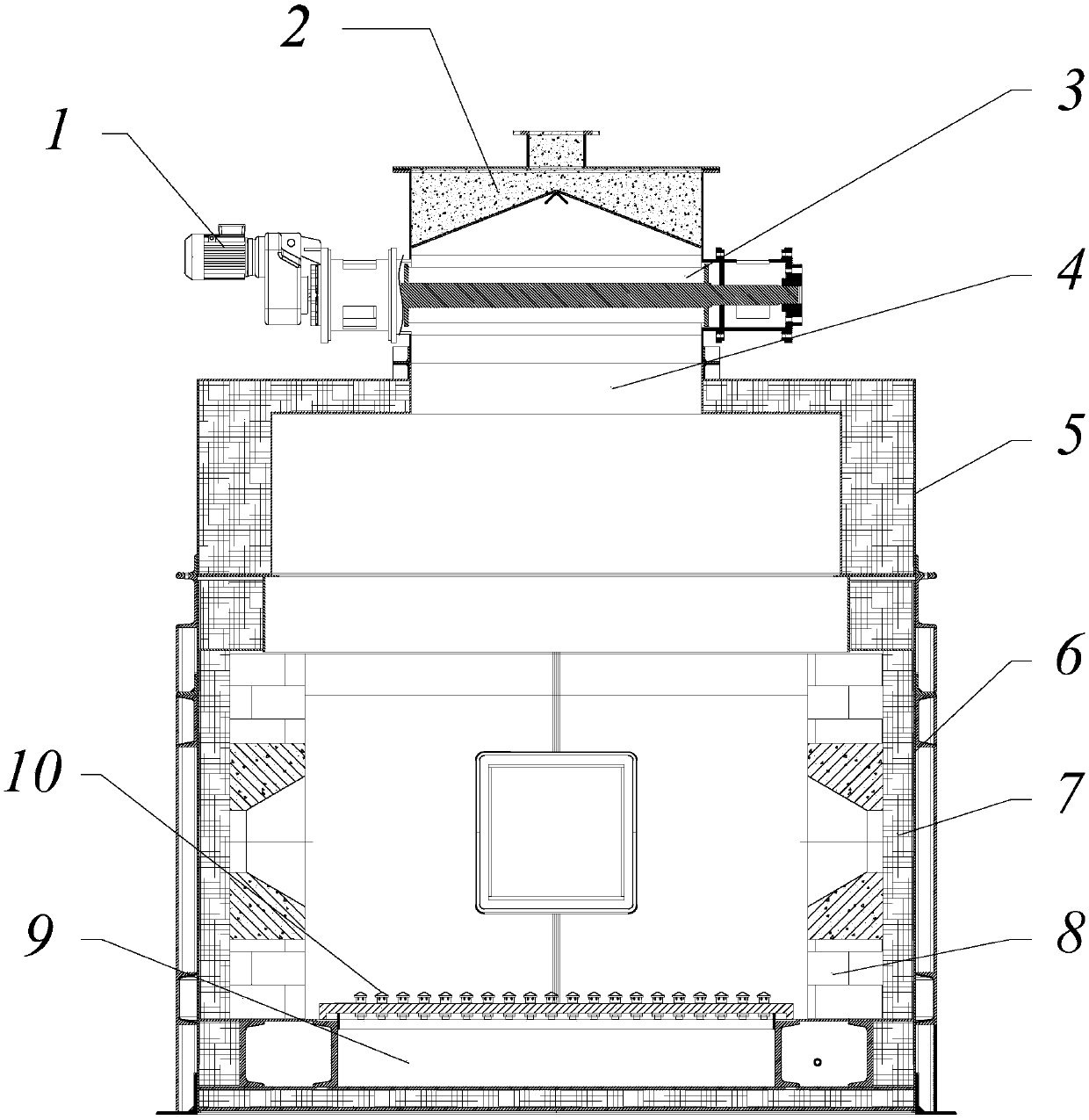

[0038]A method for recycling foundry waste sand based on compound roasting equipment, comprising the following steps:

[0039] S1. The material enters the receiving trough through the equalizing plate (not shown in the drawings), then enters the feeding protection device through the impeller and then enters the combustion chamber of the horizontal combustion chamber;

[0040] S2. The material is blown and boiled by the hot air at the bottom of the combustion chamber, and flows from the combustion chamber to the air separation and miscellaneous removal chamber. During this period, the three-stage roasting is carried out sequentially through the combustion gun. The temperature of the first-stage roasting is 300°C, and the time is 10s; The temperature is 600°C, and the time is 240s; the temperature of the three-stage roasting is 850°C, and the time is 10s;

[0041] S3. After the material is roasted, it falls into the air preheating chamber from the air separation and miscellaneou...

Embodiment 2

[0049] A method for recycling foundry waste sand based on compound roasting equipment, comprising the following steps:

[0050] S1. The material enters the receiving trough through the equalizing plate (not shown in the drawings), then enters the feeding protection device through the impeller and then enters the combustion chamber of the horizontal combustion chamber;

[0051] S2. The material is blown and boiled by the hot air at the bottom of the combustion chamber, and flows from the combustion chamber to the air separation and miscellaneous removal chamber. During this period, the three-stage roasting is carried out sequentially through the combustion gun. The temperature of the first-stage roasting is 400°C, and the time is 20s; The temperature is 800°C, and the time is 180s; the temperature of the three-stage roasting is 900°C, and the time is 20s;

[0052] S3. After the material is roasted, it falls into the air preheating chamber from the air separation and miscellaneo...

Embodiment 3

[0059] A method for recycling foundry waste sand based on compound roasting equipment, characterized in that it comprises the following steps:

[0060] S1. The material enters the receiving trough through the equalizing plate (not shown in the drawings), then enters the feeding protection device through the impeller and then enters the combustion chamber of the horizontal combustion chamber;

[0061] S2. The material is blown and boiled by the hot air at the bottom of the combustion chamber, and flows from the combustion chamber to the air separation and miscellaneous removal chamber. During this period, the three-stage roasting is carried out sequentially through the combustion gun. The temperature of the first-stage roasting is 400 ° C, and the time is 15s; The temperature is 700°C, and the time is 240s; the temperature of the three-stage roasting is 850°C, and the time is 10s;

[0062] S3. After the material is roasted, it falls into the air preheating chamber from the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com