High-temperature roasting device and treatment method thereof

A technology of high-temperature roasting and processing methods, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of short maintenance period, high processing cost, and difficult processing, and achieve high production safety performance, simple process flow, and systematic running stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

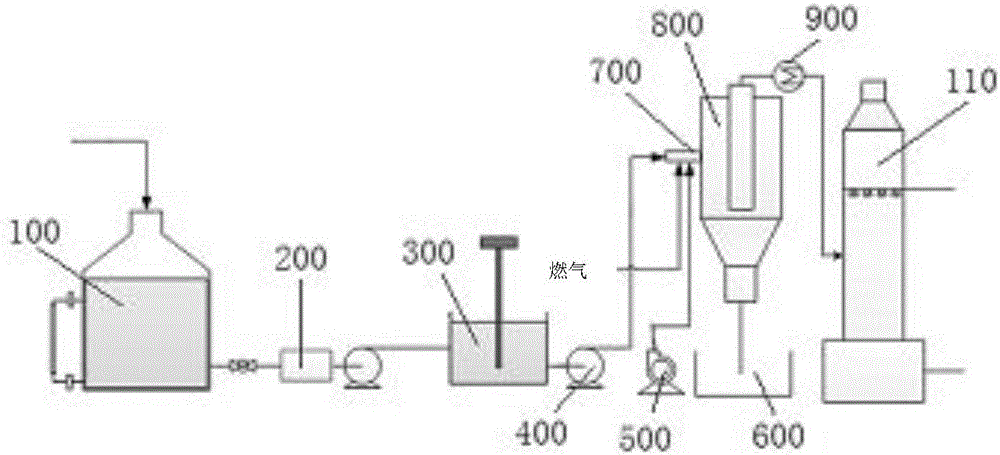

[0057] Such as figure 1 , figure 2 with image 3 , a high-temperature roasting device provided in Embodiment 1 of the present invention, including a waste liquid tank 100 , a high-pressure pump 400 , a cooling tank 600 , a spray combustion system, a combustion-supporting fan 500 and a spray device 110 .

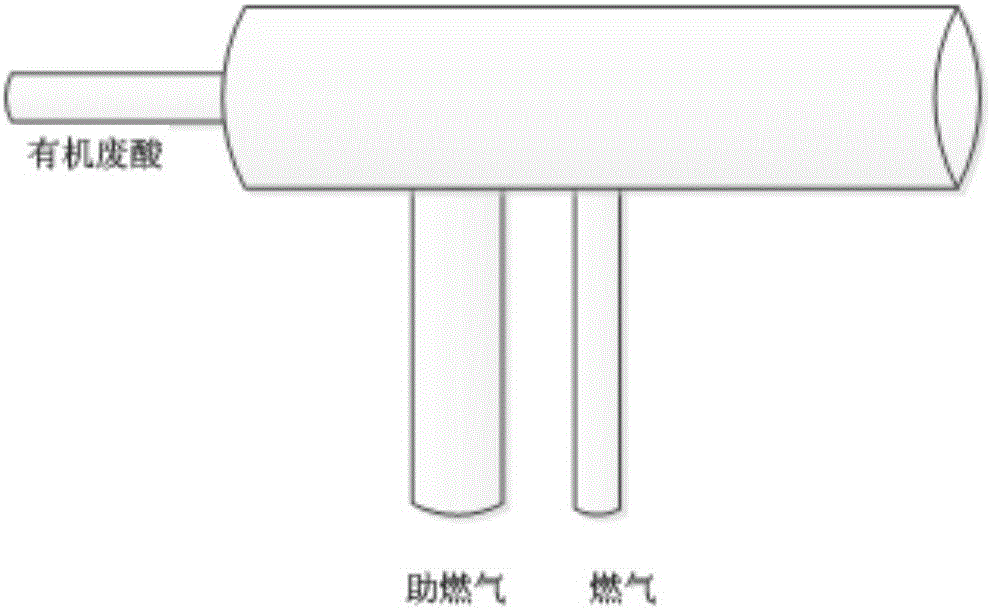

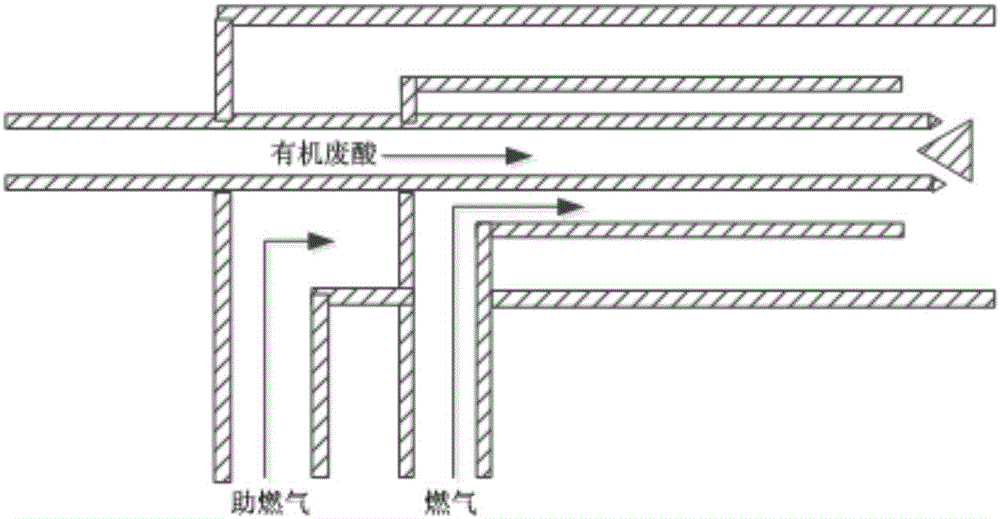

[0058] The spray combustion system includes a waste liquid pipeline, a gas pipeline, a gas-supporting pipeline, a spray combustion device 700, an atomization roaster 800 and a mist pipeline.

[0059]The spray combustion device 700 is installed tangentially inside the atomization roasting furnace 800. As a preferred embodiment, the spray combustion device 700 is installed tangentially from the top of the furnace body of the atomization roaster 800 and the surface of the furnace body, and the installation angle is lower than the horizontal line and The included angle with the horizontal line is 2°-10°, more preferably, the installation angle is 8°. The tangential installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com