Device for fully roasting pellets in belt type roasting machine

A belt roaster and full roasting technology, applied in the furnace type, furnace, lighting and heating equipment, etc., can solve the problems of affecting the quality of pellets, inconsistent roasting of raw meal layers, etc., to ensure roasting, prevent sticking, improve Effect of pellet roasting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

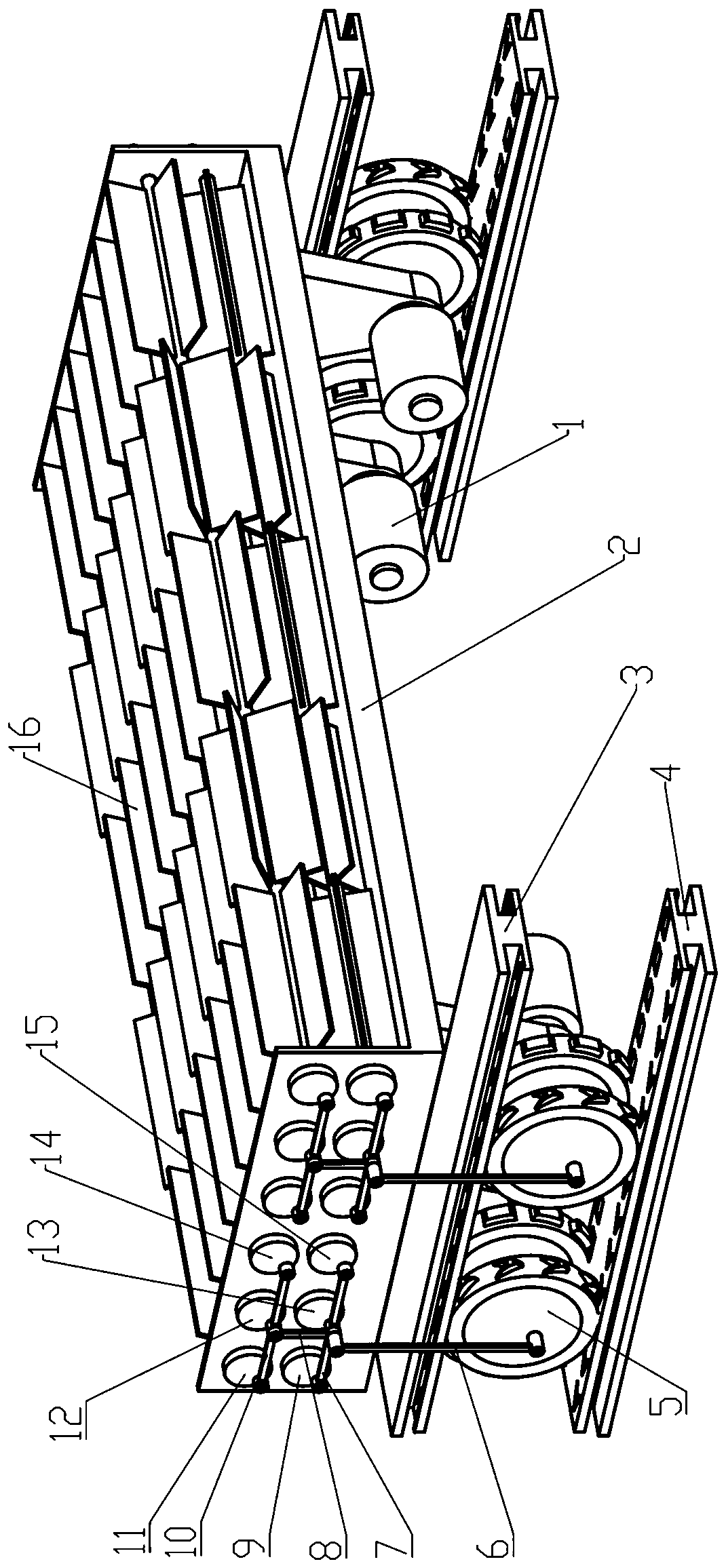

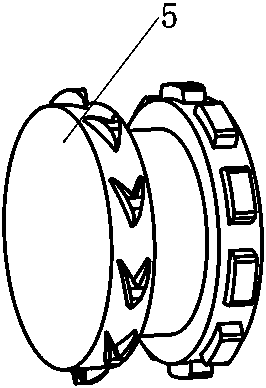

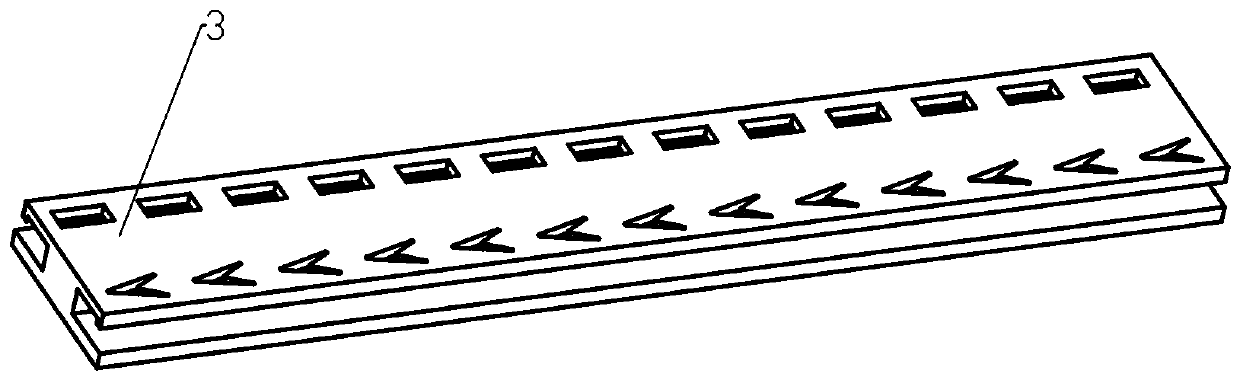

[0023] Such as Figure 1-3 As shown, a device for fully roasting pellets in a belt roaster according to the present invention, the power system is mainly composed of double meshing wheels 5, upper guide rail 3, lower guide rail 4, roller 1, power Composed of connecting rods 6, two front and rear rollers 1 are arranged on both sides of the lower end of the trolley 2, and the two rollers 1 are fixed coaxially with the double meshing wheels 5 respectively, and the double meshing wheels 5 are arranged between the upper guide rail 3 and the lower guide rail 4, The roller 1 corresponds to the planetary wheel in the belt roaster and is in a state of being moved by the double meshing wheel 5 to make the trolley 2 move between the upper and lower guide rails on both sides; the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com