Pellet roasting system and method based on sintering machine

A sintering machine and pelletizing technology, applied in the field of pellet roasting, can solve the problems of poor cooling effect, large floor space and high cost, and achieve the effects of increasing production capacity, reducing floor space and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

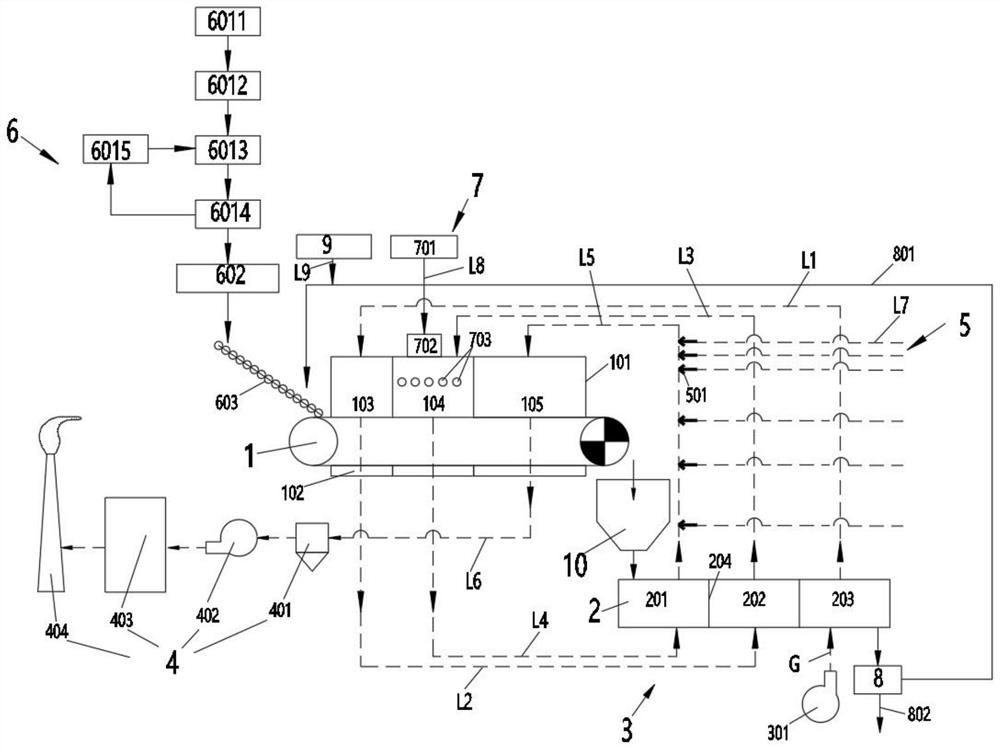

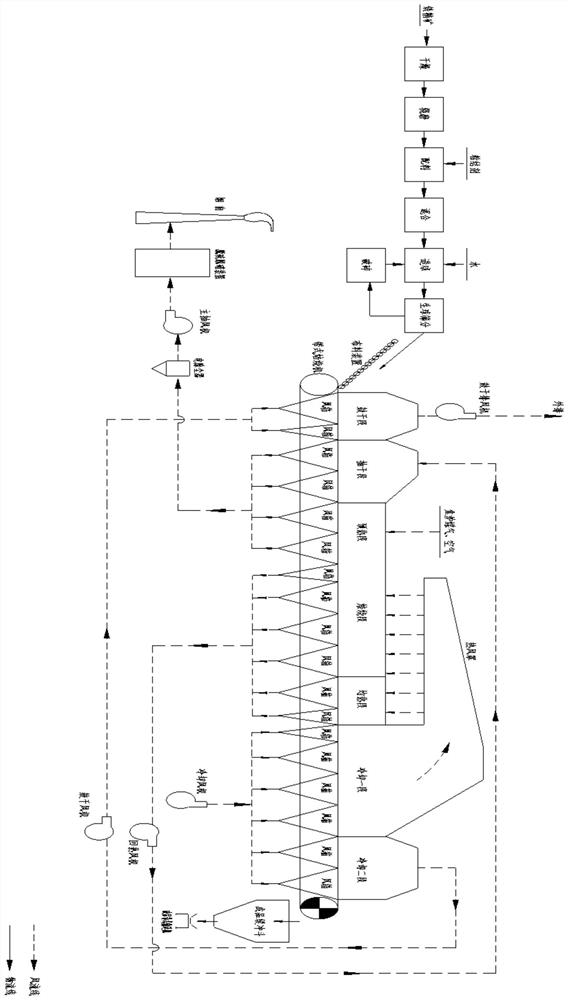

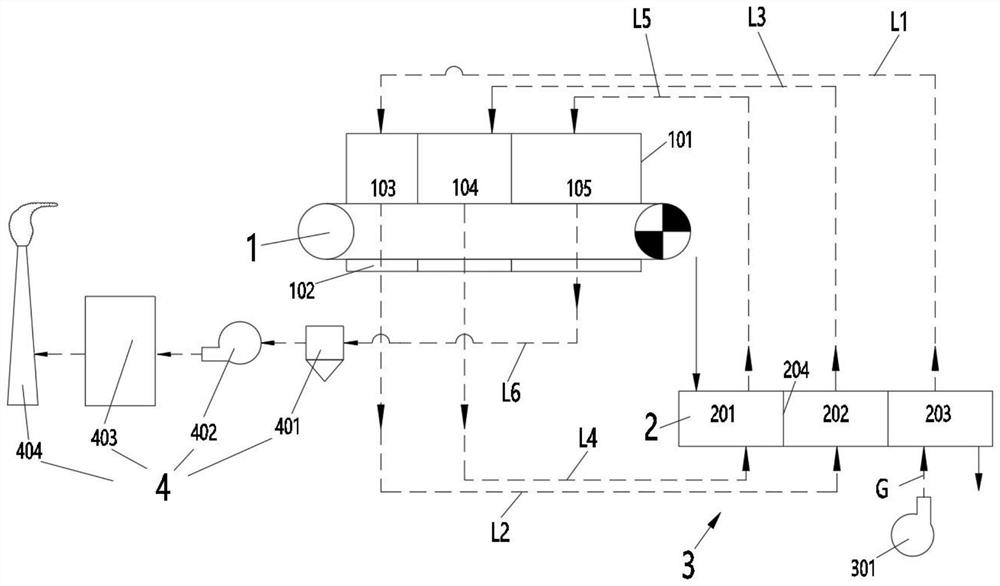

[0103] A pellet roasting system based on a sintering machine, the system includes: a sintering machine 1 , an annular cooler 2 , a circulating air flow unit 3 and a flue gas treatment unit 4 . The discharge port of the sintering machine 1 is connected with the feed port of the annular cooler 2 . The circulating air flow unit 3 is arranged between the sintering machine 1 , the annular cooler 2 and the flue gas treatment unit 4 . A fume hood 101 is arranged above the sintering machine 1 , and a wind box 102 is arranged below it. According to the direction of materials, the fume hood 101 located above the sintering machine 1 is divided into a preheating section 103 , a combustion section 104 and a roasting section 105 in sequence. The annular cooler 2 is sequentially divided into a first annular cooling section 201 , a second annular cooling section 202 and a third annular cooling section 203 . The wind boxes 102 located at the bottoms of the roasting section 105, the combustio...

Embodiment 2

[0105] Such as figure 2 As shown, Embodiment 1 is repeated, except that the air circulation unit 3 includes a cooling fan 301 and a circulation pipeline. The circulation pipeline specifically includes: the cooling fan 301 communicates with the air inlet of the third ring cooling section 203 through the air inlet pipe G. The air outlet of the third ring cooling section 203 communicates with the air inlet of the preheating section 103 through the first gas pipeline L1. The air outlet of the preheating section 103 communicates with the air inlet of the second ring cooling section 202 through the second gas pipeline L2. The air outlet of the second ring cooling section 202 communicates with the air inlet of the combustion section 104 through the third gas pipeline L3. The air outlet of the combustion section 104 communicates with the air inlet of the ring cooling section 201 through the fourth gas pipeline L4. The air outlet of the annular cooling section 201 is connected with ...

Embodiment 3

[0107] Example 2 is repeated, except that the fifth gas pipeline L5 is provided with a supplementary heat device 5 . The heating device 5 includes a burner 501 and a gas delivery pipeline L7. The burner 501 is arranged in the fifth gas pipeline L5. The air inlet of the burner 501 communicates with the air outlet of the gas delivery pipeline L7.

[0108] The heating device 5 includes several burners 501 . The several burners 501 are all arranged in the fifth gas pipeline L5, and the several burners 501 are independently connected to the gas delivery pipeline L7. In the fifth gas pipeline L5, along the direction of the gas flow, the number of burners 501 is distributed in an increasing manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com