Method for preparing type II anhydrous gypsum by fluidizing and roasting beta-semi-hydrated gypsum

A fluidized roasting and hemihydrate gypsum technology, which is applied in the field of gypsum powder calcination, can solve the problems of low strength, inability to homogenize qualified products, and low output of type II anhydrite, achieve efficient mass and heat transfer, and improve roasting. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

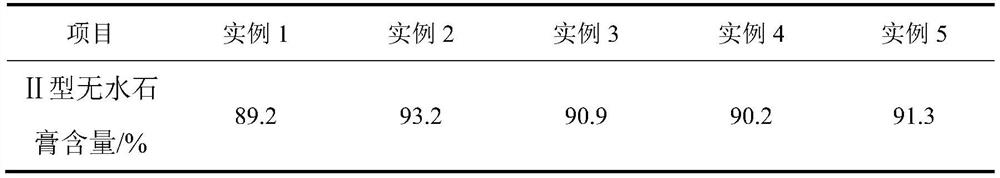

Examples

Embodiment 1

[0018] Embodiment 1: β-hemihydrate gypsum powder raw material is crossed 80 order sample sieves, takes by weighing 110g and puts into the small-sized fluidized bed, and the control gas-solid ratio is 0.2409L (g min)-1 to reach better fluidized state. Heating to 800°C at a heating rate of 10°C / min, fluidized heat preservation and roasting for 120min, after the roasting, naturally cooling to room temperature, and finally obtaining type II anhydrous gypsum.

Embodiment 2

[0019] Embodiment 2: β-hemihydrate gypsum powder raw material is crossed 80 order sample sieves, takes by weighing 110g and puts into the small-sized fluidized bed, and the control gas-solid ratio is 0.2409L (g min)-1 to reach better fluidized state. Heating to 800°C at a heating rate of 10°C / min, fluidized heat preservation and roasting for 150 minutes, after the roasting, naturally cooling to room temperature, and finally obtaining type II anhydrous gypsum.

Embodiment 3

[0020] Embodiment 3: β-hemihydrate gypsum powder raw material is crossed 80 order sub-sieves, takes by weighing 110g and puts into the small-sized fluidized bed, and the control gas-solid ratio is 0.2409L (g min)-1 to reach better fluidized state. Heating to 800°C at a heating rate of 10°C / min, fluidized heat preservation and roasting for 180min, after the roasting, naturally cooling to room temperature, and finally obtaining type II anhydrous gypsum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com