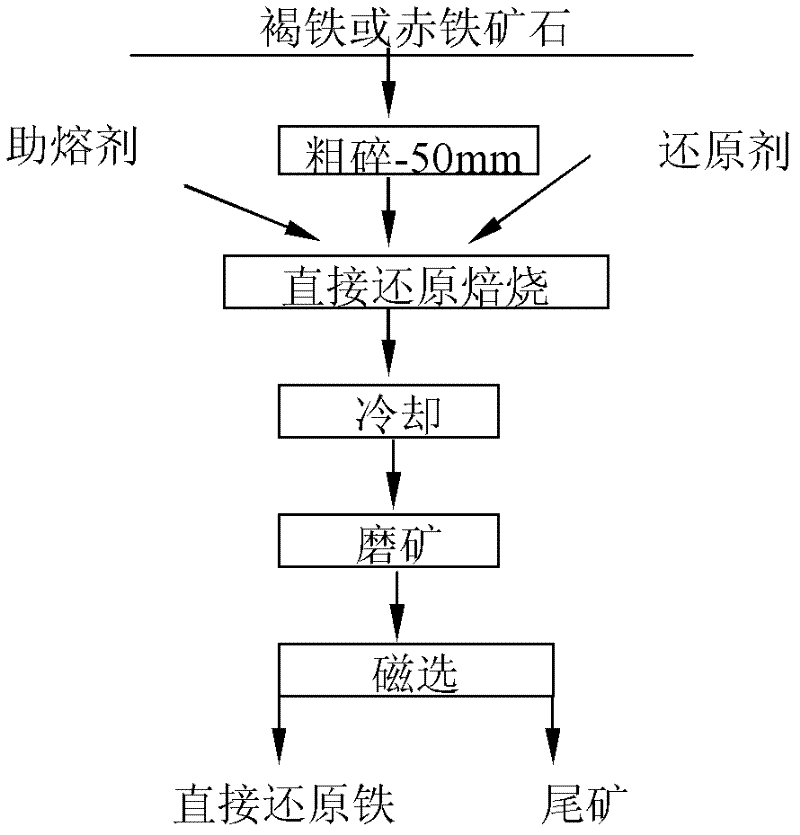

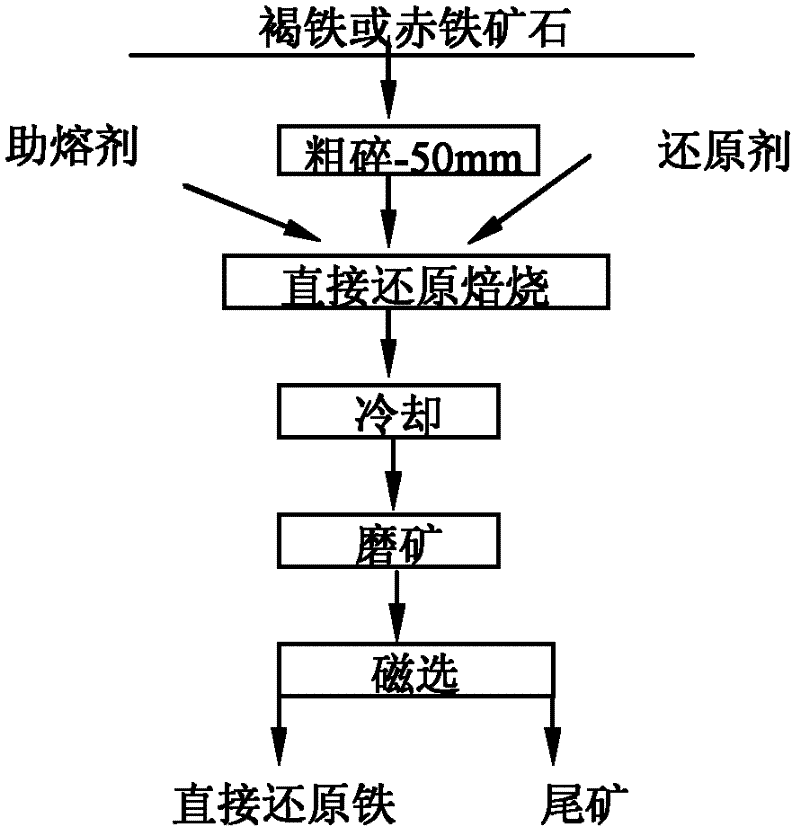

A process for producing direct reduced iron from large-grained limonite and hematite ores

A process method and iron ore technology, applied in the direction of fluidized bed furnace, etc., can solve the problem of limited scale of reduced iron, and achieve the effects of saving investment costs, expanding production scale, and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The total iron content of a limonite is 49.55%, and the main gangue mineral is quartz. 500g of raw ore is roughly crushed to 100% -50mm, adding reducing agent and flux, the amount of reducing agent is 30%; after mixing, reduce and roast at 1200°C for 120min; cool; grind at a concentration of about 60% to a particle size of -0.074mm 51%, magnetic separation at a magnetic field strength of 198.73kA / m. Obtain direct reduced iron with an iron grade of 90.2% and an iron recovery rate of 89.3%.

Embodiment 2

[0016] The raw material is a hematite ore containing 33.48% iron, and the main gangue mineral is quartz. 500g of raw ore is coarsely crushed to 100% -50mm, adding reducing agent and fluxing agent, the amount of reducing agent is 30%; after mixing, reducing and roasting at 1200°C for 240min; cooling; two-stage grinding, magnetic separation at both ends, magnetic field strength 198.73kA / m. Direct reduced iron with an iron grade of 89.3% and a recovery rate of 83.37% was obtained.

Embodiment 3

[0018] The total iron content of a limonite is 33.75%, and the main gangue mineral is quartz. 500g of raw ore is coarsely crushed to 100% -50mm, adding reducing agent and fluxing agent, the amount of reducing agent is 30%, and fluxing agent is 5%; after mixing, reduce and roast at 1200°C for 180min; cool; grind at a concentration of about 60%. Ore 30min to particle size -0.074mm accounted for 85%, magnetic separation at a magnetic field strength of 198.73kA / m. Obtain direct reduced iron with an iron grade of 89.92% and an iron recovery rate of 94.93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com