A method for recovering valuable metal from waste lithium battery

A waste lithium battery and valuable metal technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problems of low metal recovery rate, complex production process, low grade of cobalt ore, etc., to improve the roasting efficiency , Optimize the working environment, the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

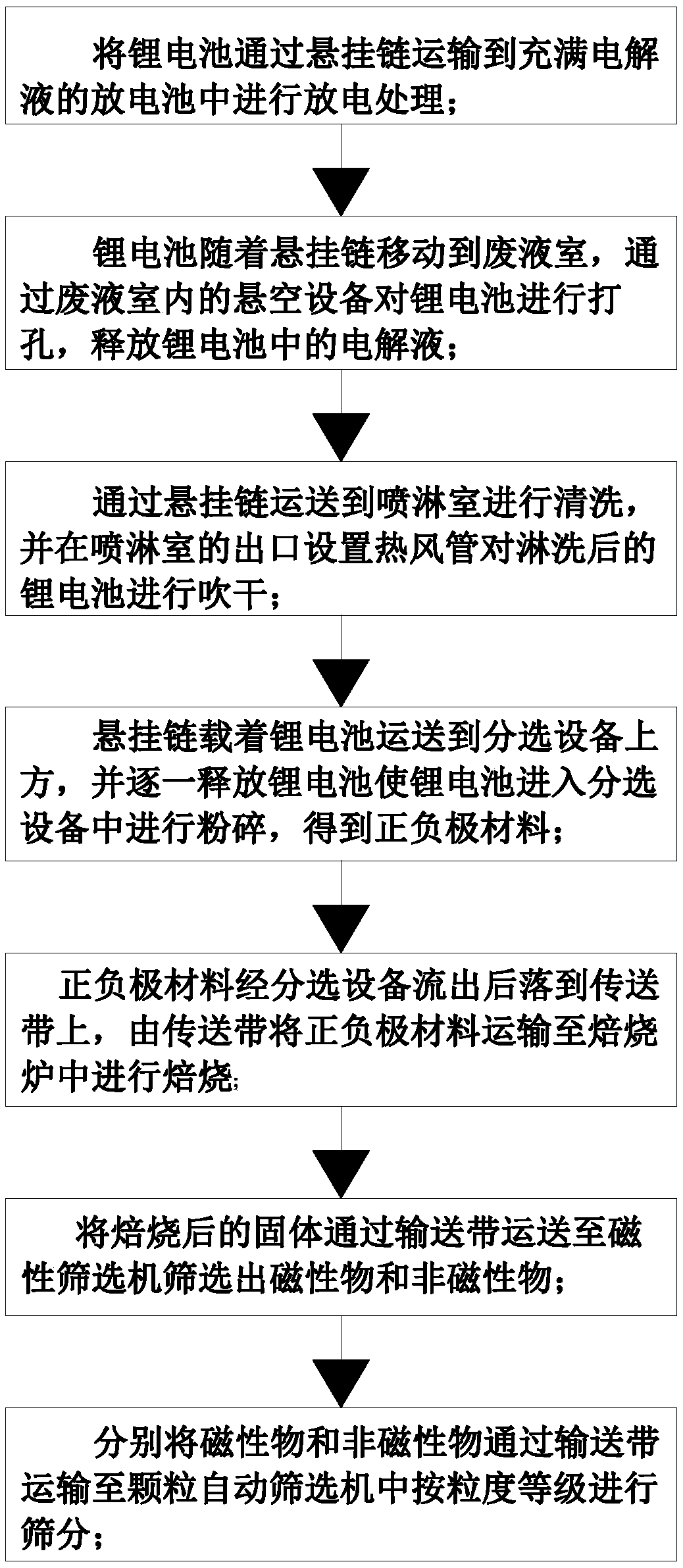

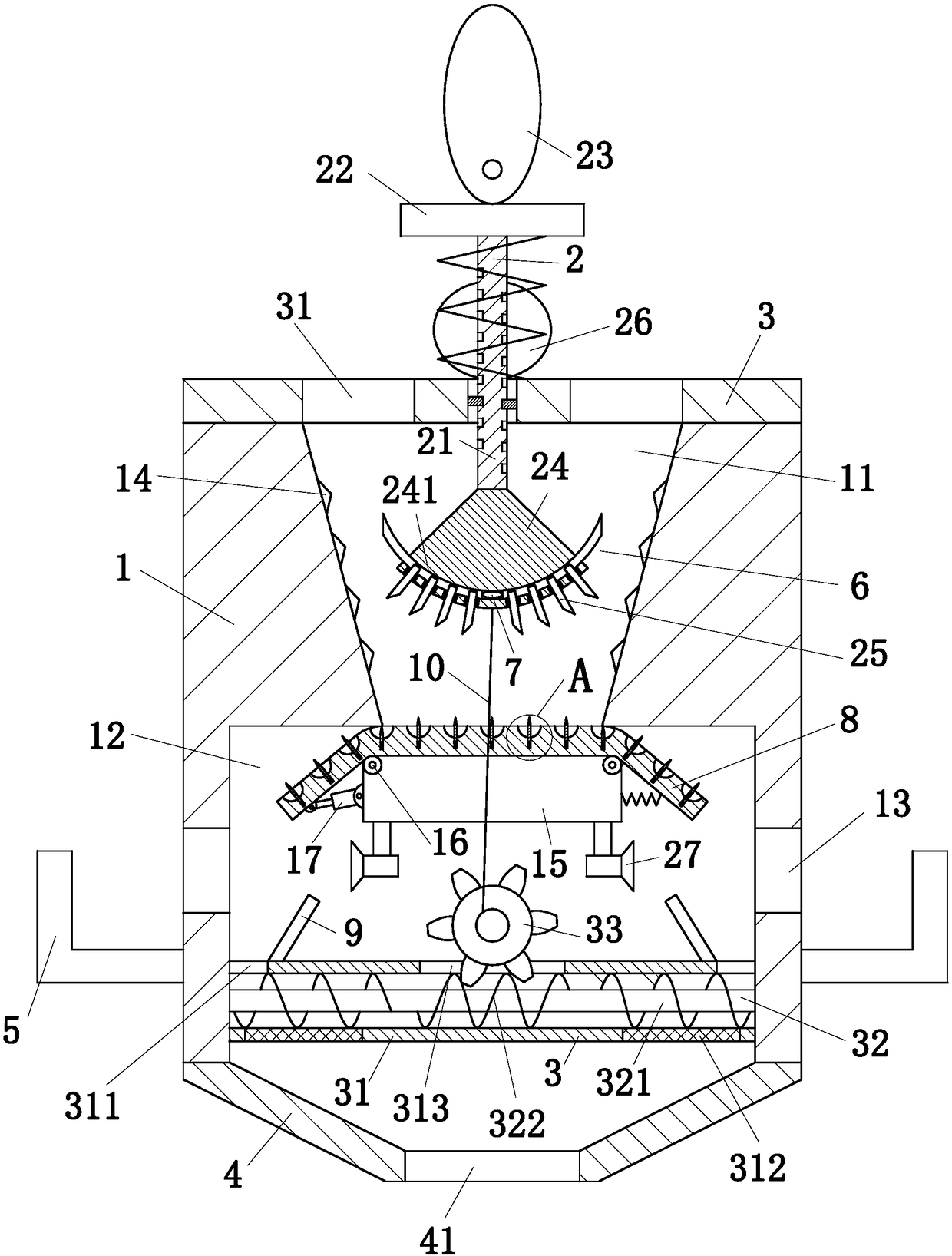

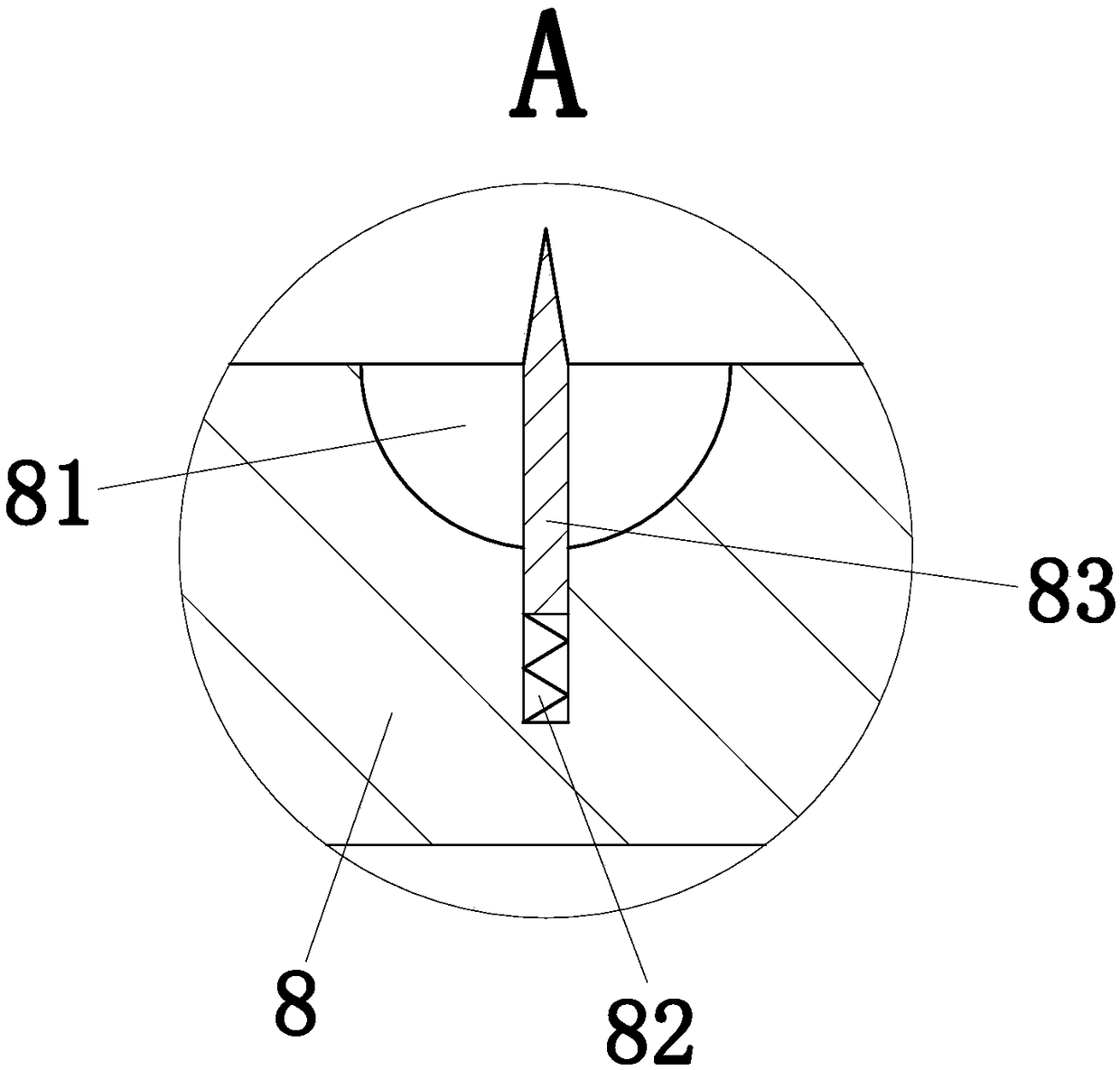

[0027] use Figure 1-Figure 3 A method for recovering valuable metals from waste lithium batteries according to an embodiment of the present invention is described as follows.

[0028] Such as figure 1 with figure 2 Shown, a kind of recovery method of the valuable metal of spent lithium battery of the present invention, this method comprises the steps:

[0029] S1: Transport the lithium battery to the discharge battery filled with electrolyte through the suspension chain for discharge treatment;

[0030] S2: After the lithium battery is discharged in S1, it moves to the waste liquid chamber with the suspension chain, and the lithium battery is punched through the suspended equipment in the waste liquid chamber to release the electrolyte in the lithium battery;

[0031] S3: After the lithium battery releases the electrolyte through S2, it is transported to the spray room for cleaning through the suspension chain, and a hot air pipe is installed at the outlet of the spray ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com