Method for producing nickel carbonyl powder from nickel hydroxide

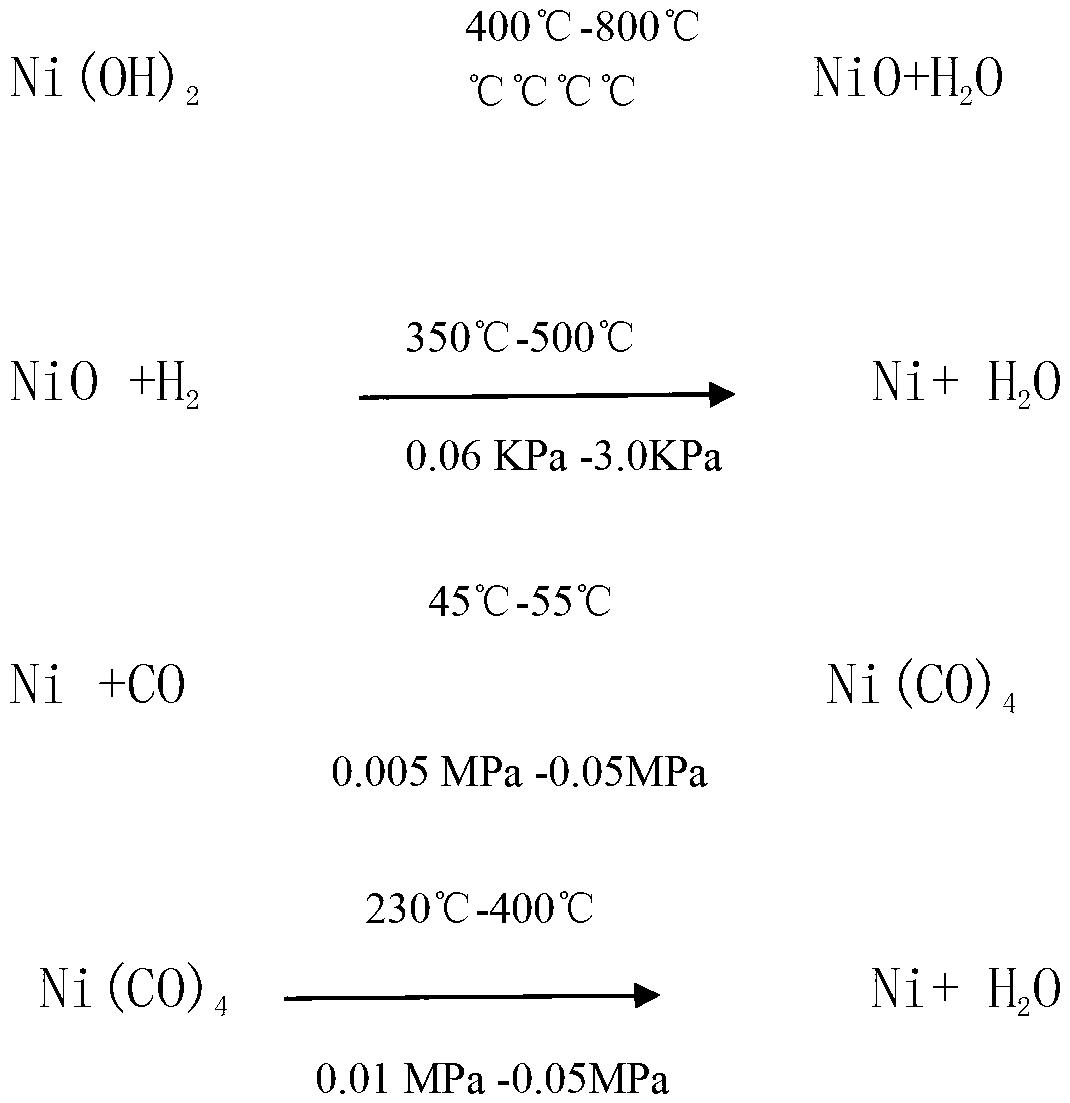

A technology of nickel hydroxide and nickel carbonyl powder, which is applied in the field of powder metallurgy, can solve the problems of limited production cost of carbonyl nickel powder, low degree of automation, and high raw material cost, and achieve high roasting and synthesis efficiency, simple production process, and low roasting temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Nickel hydroxide raw material composition:

[0028] Ni

[0029] Add nickel hydroxide raw material with the speed of 1000kg per hour in the rotary roaster, the raw material moisture content is 50%, the reaction kettle rotation rate is set as 1 rev / min, the material residence time is 1.5 hours, feed hot gas and air during the reaction, The reaction temperature is controlled at 450°C; the nickel oxide obtained by the reaction is transported to the hydrogen reduction furnace, the reaction temperature is 350°C, the reaction pressure is 0.06kpa, and the reduction is carried out under the hydrogen atmosphere to generate elemental active nickel; the elemental active nickel is passed through the screw conveyor Send it into the rotating nickel carbonyl synthesis reactor for oxo synthesis reaction with CO gas, the reaction time is 18 hours, the reaction pressure is 0.005MPa, CO and the material are in countercurrent contact; the synthesized nickel carbonyl gas is transpor...

Embodiment 2

[0031] Nickel hydroxide raw material composition:

[0032] Ni

[0033] Add the nickel hydroxide raw material with the speed of 1000kg per hour in the rotary roaster, the raw material moisture content is 60%, the reaction kettle rotation rate is set as 1.5 rev / min, the material residence time is 1 hour, feed hot gas and air during the reaction, The reaction temperature is controlled at 450°C; the nickel oxide obtained by the reaction is transported to the hydrogen reduction furnace, the reaction temperature is 400°C, the reaction pressure is 0.1kpa, and the reduction is carried out under the hydrogen atmosphere to generate elemental active nickel; the elemental active nickel passes through the screw conveyor Send it into the rotating nickel carbonyl synthesis reactor for oxo synthesis reaction with CO gas, the reaction time is 30 hours, the reaction pressure is 0.005MPa, CO and the material are in countercurrent contact; the synthesized nickel carbonyl gas is transport...

Embodiment 3

[0035] Nickel hydroxide raw material composition:

[0036] Ni

[0037] Add nickel hydroxide raw material with the speed of 1000kg per hour in the rotary roaster, the raw material moisture content is 50%, the reaction kettle rotation rate is set as 1 rev / min, the material residence time is 1.5 hours, feed hot gas and air during the reaction, The reaction temperature is controlled at 450°C; the nickel oxide obtained by the reaction is transported to the hydrogen reduction furnace, the reaction temperature is 400°C, the reaction pressure is 0.1kpa, and the reduction is carried out under the hydrogen atmosphere to generate elemental active nickel; the elemental active nickel passes through the screw conveyor Send it into the rotating nickel carbonyl synthesis reactor for oxo synthesis reaction with CO gas, the reaction time is 24 hours, the reaction pressure is 0.01MPa, CO and the material are in countercurrent contact; the synthesized nickel carbonyl gas is transported t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com