Airlift reactor having spiral porous sieve plate

An airlift reactor and porous sieve plate technology, which is applied in the fields of chemical engineering, biological engineering and environmental engineering, can solve the problem of reducing the effective range of airlift reactors, unfavorable gas-liquid two-phase efficient mass transfer, and difficult reactor cleaning Operation and other issues, to achieve the effect of broadening the effective operating range, improving the gas-liquid mass transfer process, and strengthening microscopic mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

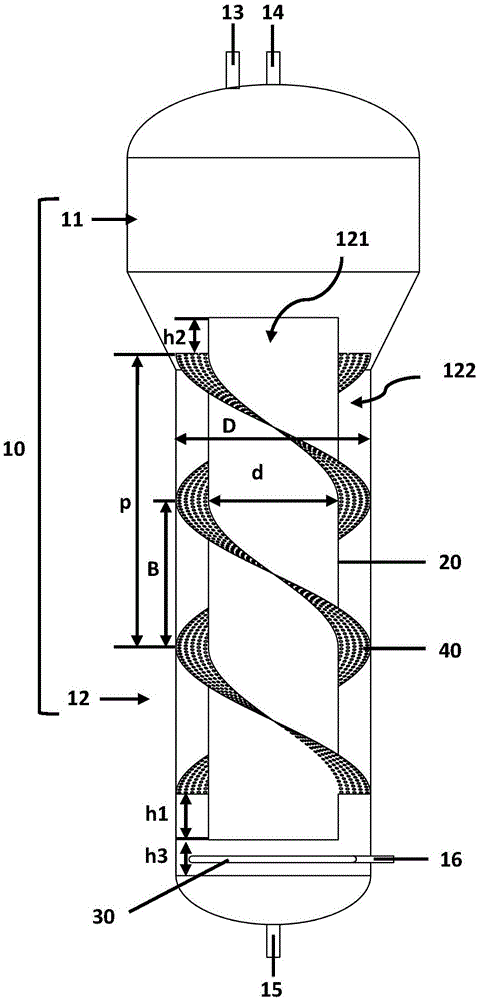

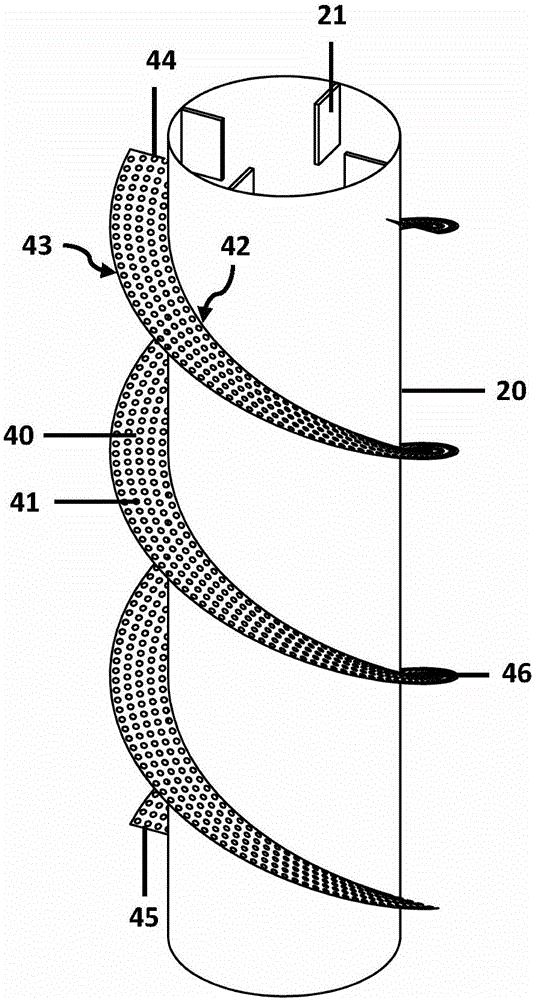

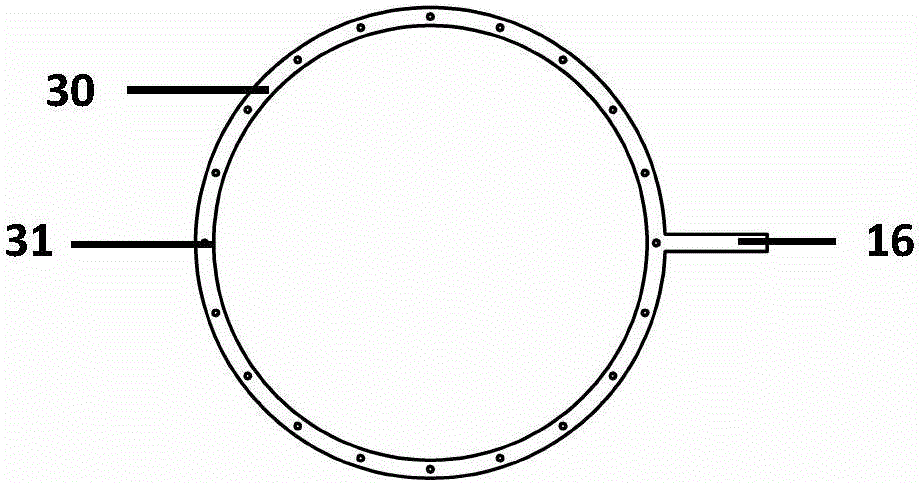

[0058] see Figure 1 to Figure 3 , as shown in the legend therein, an air-lift reactor with a spiral porous sieve plate is used for gas-liquid two-phase reaction, including a reaction tank body 10, and the internal space of the reaction tank body 10 is allocated as a gas-lift reactor located on the lower side The liquid mixing zone 12 and the gas-liquid separation zone 11 located on the upper side, the gas-liquid mixing zone 12 are provided with a guide tube 20 and a gas distributor 30 up and down, the guide tube 20 is coaxially arranged with the reaction tank body 10 and separates the gas-liquid The mixing zone 12 is divided into a circular descending section 121 located inside the draft tube 20 and an annular rising section 122 located outside the draft tube 20. The gas distributor 30 feeds air into the annular rising section 122, and the airlift reactor also Including the spiral perforated sieve plate 40 installed in the annular ascending section 122 , the plate body of the...

Embodiment 2

[0081] see Figure 4 to Figure 6 , as shown in the legend therein, an air-lift reactor with a spiral porous sieve plate is used for gas-liquid two-phase reaction, including a reaction tank body 10, and the internal space of the reaction tank body 10 is allocated as a gas-lift reactor located on the lower side The liquid mixing zone 12 and the gas-liquid separation zone 11 located on the upper side, the gas-liquid mixing zone 12 are provided with a guide tube 20 and a gas distributor 30 up and down, the guide tube 20 is coaxially arranged with the reaction tank body 10 and separates the gas-liquid The mixing zone 12 is divided into a circular rising section 123 located inside the draft tube 20 and an annular descending section 124 located outside the draft tube 20. The gas distributor 30 feeds air into the circular rising section 123, and the airlift reactor It also includes a spiral perforated sieve plate 40 installed in the circular ascending section 123 , the plate body of t...

Embodiment 3

[0106] All the other are identical with embodiment one, and difference is that the airlift reactor among the present embodiment is used for ventilated culture microorganism, animal cell and plant cell, air flow (m 3 / min) and culture medium volume (m 3 ) ratio of 0.1 to 3, the value tends to the upper limit for small-scale reactors, and the lower limit for medium-scale and large-scale reactions, but the specific operating parameters should be determined according to the actual oxygen consumption requirements of microorganisms. The operating pressure (gauge pressure) is generally 0.2 to 2.0 atm.

[0107] In one embodiment, the reaction tank body, the draft tube and the spiral porous sieve plate are made of transparent materials, so as to be suitable for the photoreaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com