Slurry pump cylinder sleeve internal surface electroplating restoration anode rotation vibrating apparatus

A technology of vibrating device and rotating device, applied in the direction of electrodes, etc., can solve problems such as difficult operation of electroplating repair device, difficult gas precipitation on the surface of plated parts, etc., so as to improve concentration polarization, improve coating compactness, and improve mass transfer conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the drawings:

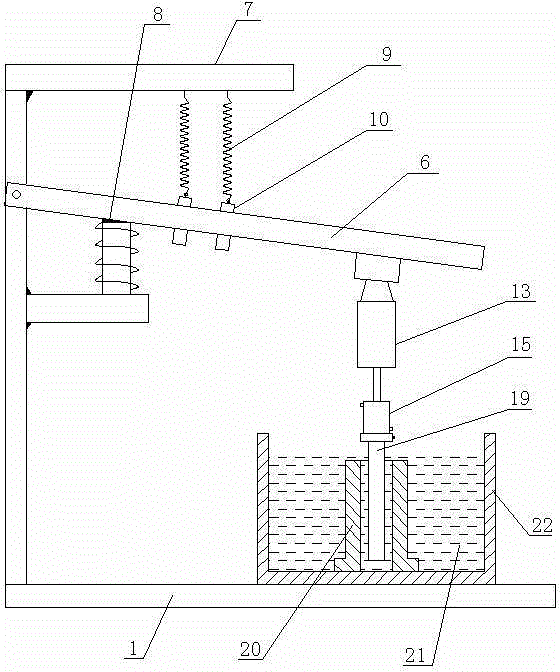

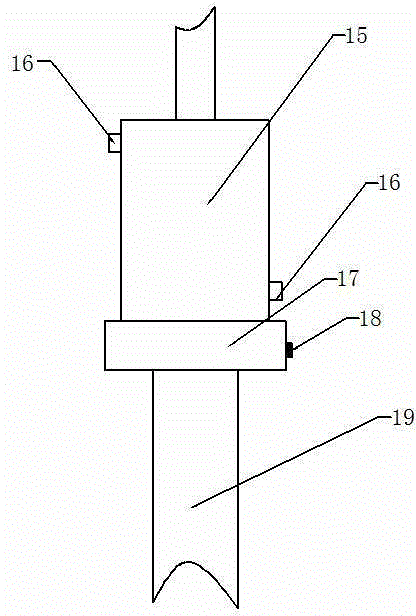

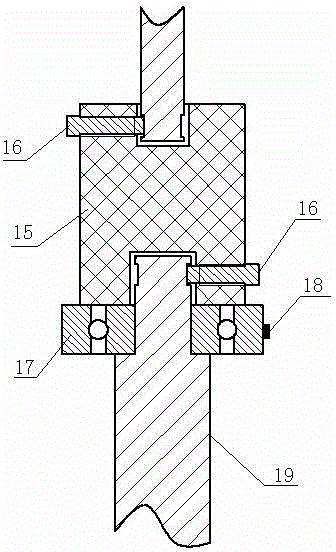

[0032] Combine figure 1 , figure 2 As shown, the anode rotary vibration device for electroplating repair on the inner surface of the mud pump cylinder liner includes a bracket, a vibration beam 6, an electromagnet 4, a spring 9, an anode rotation device, a plating tank 21, a programmable logic controller PLC, and a vibration beam 6 One end is movably connected to the bracket through a pin 5. Two springs 9 are installed between the vibrating beam 6 and the upper bracket beam 7, and the upper ends of the two springs 9 are welded to the lower end surface of the beam 7, and the lower ends of the two springs 9 pass The fixed adjustment knob 10 is connected with the vibration beam 6, refer to Figure 5 , The adjusting knob 10 is a bolt with a ring, the ring is set at the end of the screw, the vibration beam 6 is provided with a screw hole, the bolt 16 is threaded with the vibration beam 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com