In-situ repairing method of heavy metal polluted soil

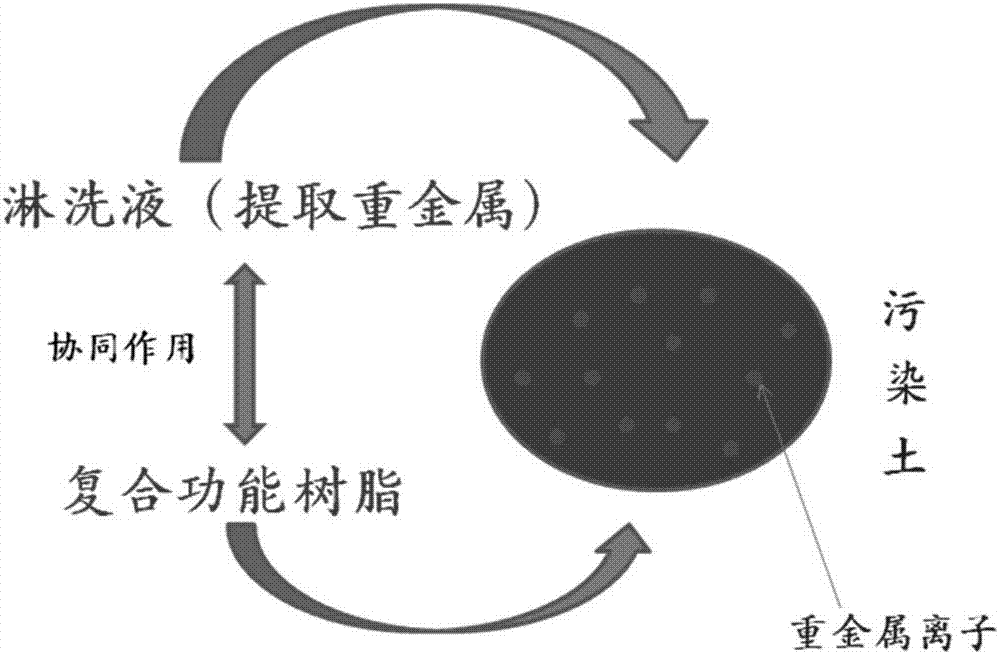

An in-situ remediation and contaminated soil technology, applied in the field of remediation of heavy metal-contaminated soil, can solve the problems of high remediation cost, secondary pollution, and inability to remediate heavy metal-contaminated soil in situ, achieving cost reduction, high economic benefits, and good application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

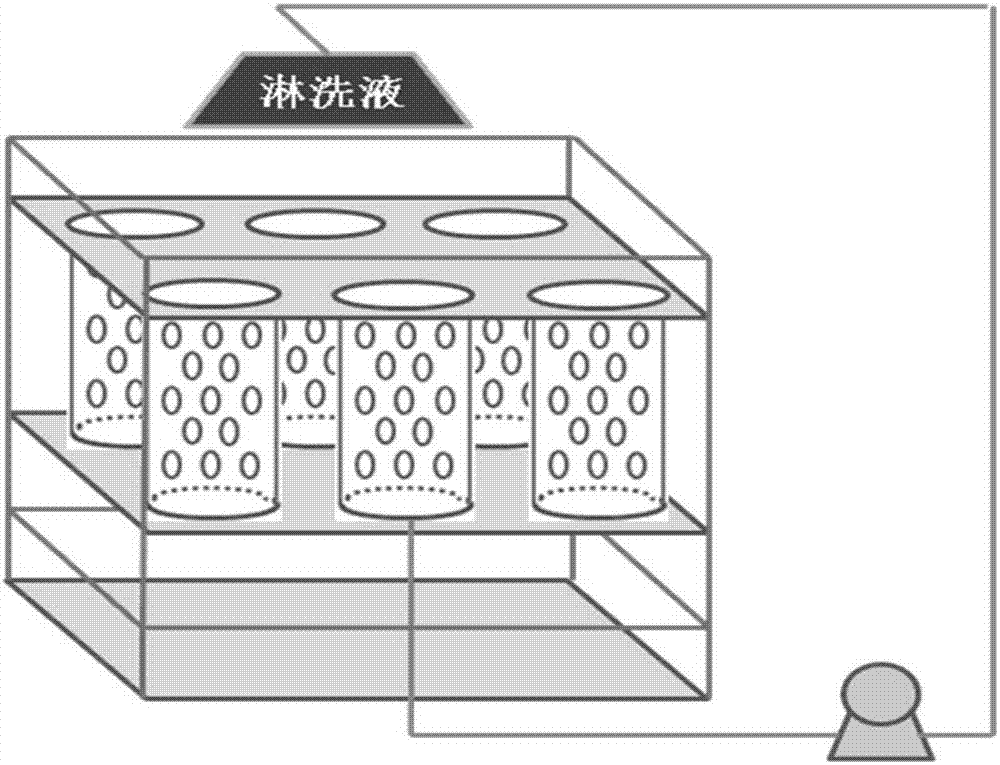

Method used

Image

Examples

Embodiment 1

[0042] Preparation of ion exchange resin loaded with zirconium phosphate:

[0043]Take by weighing 20g cation exchange resin D001, the massfraction that it is placed in 100mL is the ZrOCl of 5% (calculated as Zr) 2 The solution was fully stirred at 25°C for 20h. Then, filter out the resin particles and add them to 500mL of phosphoric acid solution with a volume fraction of 20%, and react at 60°C. Drying at lower temperature for 5 hours to obtain a composite functional resin with a zirconium loading of 13 wt%.

[0044] Preparation of ion exchange resin loaded with zirconia:

[0045] Take by weighing 50g cation exchange resin D001, it is placed in the ZrOCl of 5% (in terms of Zr) that it is placed in 200mL mass fraction 2 In the solution, react at a constant temperature of 50°C for 4 hours to fully diffuse the zirconium salt to the inner surface of the resin pores, then filter and place it in 1000mL of 5% sodium hydroxide solution, fully stir and react at room temperature for...

Embodiment 2

[0047] The concentration of lead in heavy metal lead polluted soil is 200mg / kg;

[0048] Take 3g of the above polluted soil and put it into a 100mL beaker, then disperse and bury 0.3g of composite functional resin into the polluted soil, then mix 3mL of ammonium nitrate eluent with a concentration of 0.01mol / L with the polluted soil, and mix the above Place the beaker in a horizontal shaker and vibrate for 1 day;

[0049] Wherein, the zirconium loading of the composite functional resin is 12wt%, the loaded metal compound is zirconium phosphate, and the carrier is D001 macroporous strongly acidic cation exchange resin;

[0050] The lead concentration in the polluted soil was determined to be 57mg / kg, and the remediation rate of the polluted soil can reach 71.5%.

Embodiment 3

[0052] The concentration of lead in heavy metal lead polluted soil is 1000mg / kg;

[0053] Take 3g of the above-mentioned polluted soil and put it into a 100mL beaker, then disperse and bury 0.3g of composite functional resin into the polluted soil, then mix 3mL of ammonium nitrate eluent with a concentration of 0.1mol / L with the polluted soil, and mix the above-mentioned Place the beaker in a horizontal shaker and vibrate for 1 day;

[0054] Wherein, the zirconium loading of the composite functional resin is 10wt%; the loaded metal compound is zirconium phosphate, and the carrier is D001 macroporous strongly acidic cation exchange resin;

[0055] The concentration of lead in the measured soil is 346mg / kg, and the remediation rate of contaminated soil can reach 65.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com