Injection type spiral stirrer for molten iron desulphurization

A spiral agitator and molten iron desulfurization technology, applied to mixers with rotary agitation devices, agitation devices, chemical instruments and methods, etc., can solve the problems of shortening the service life of agitation blades, reduce shear power consumption, increase Entrainment circulation flow, the effect of improving the stress situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

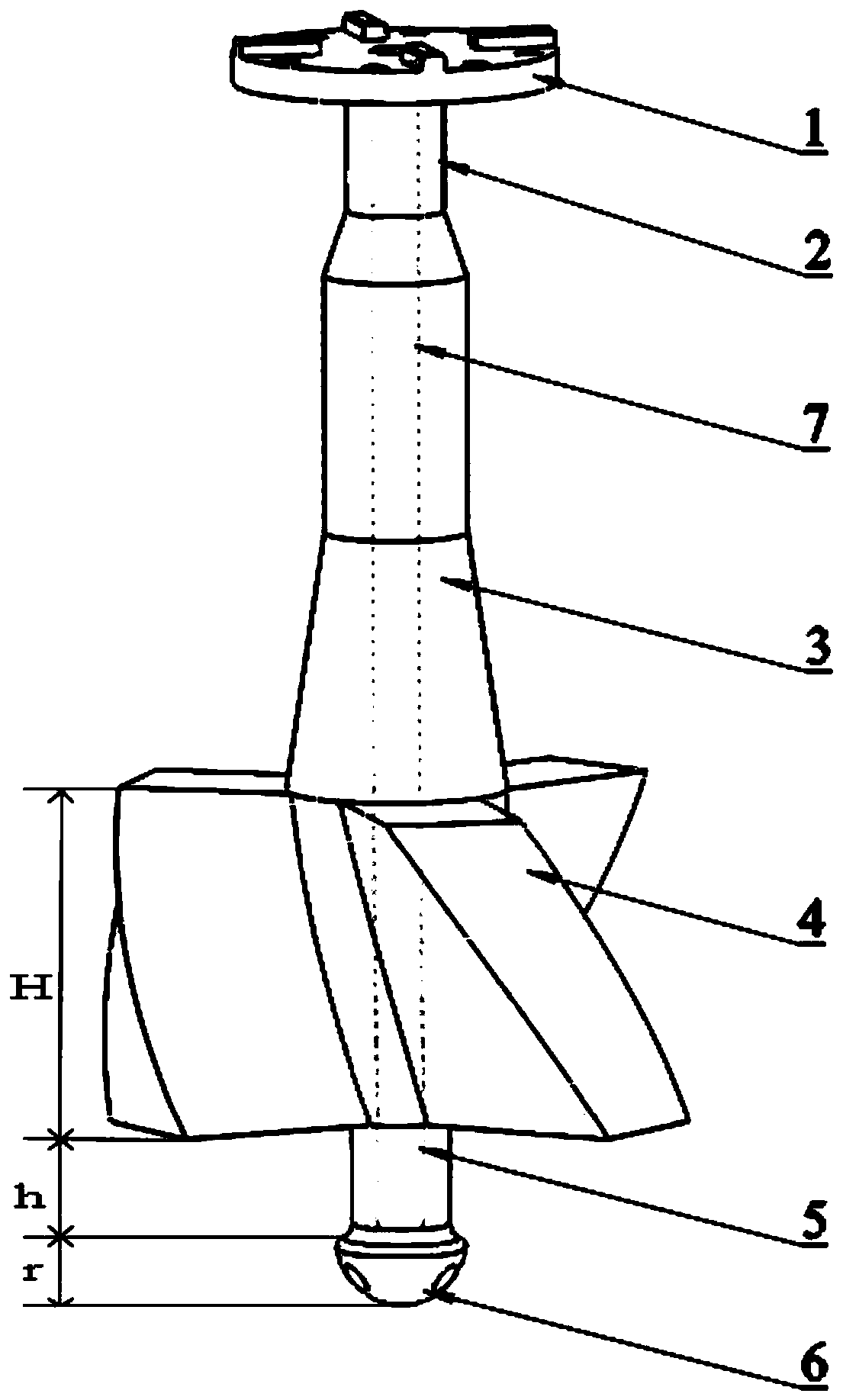

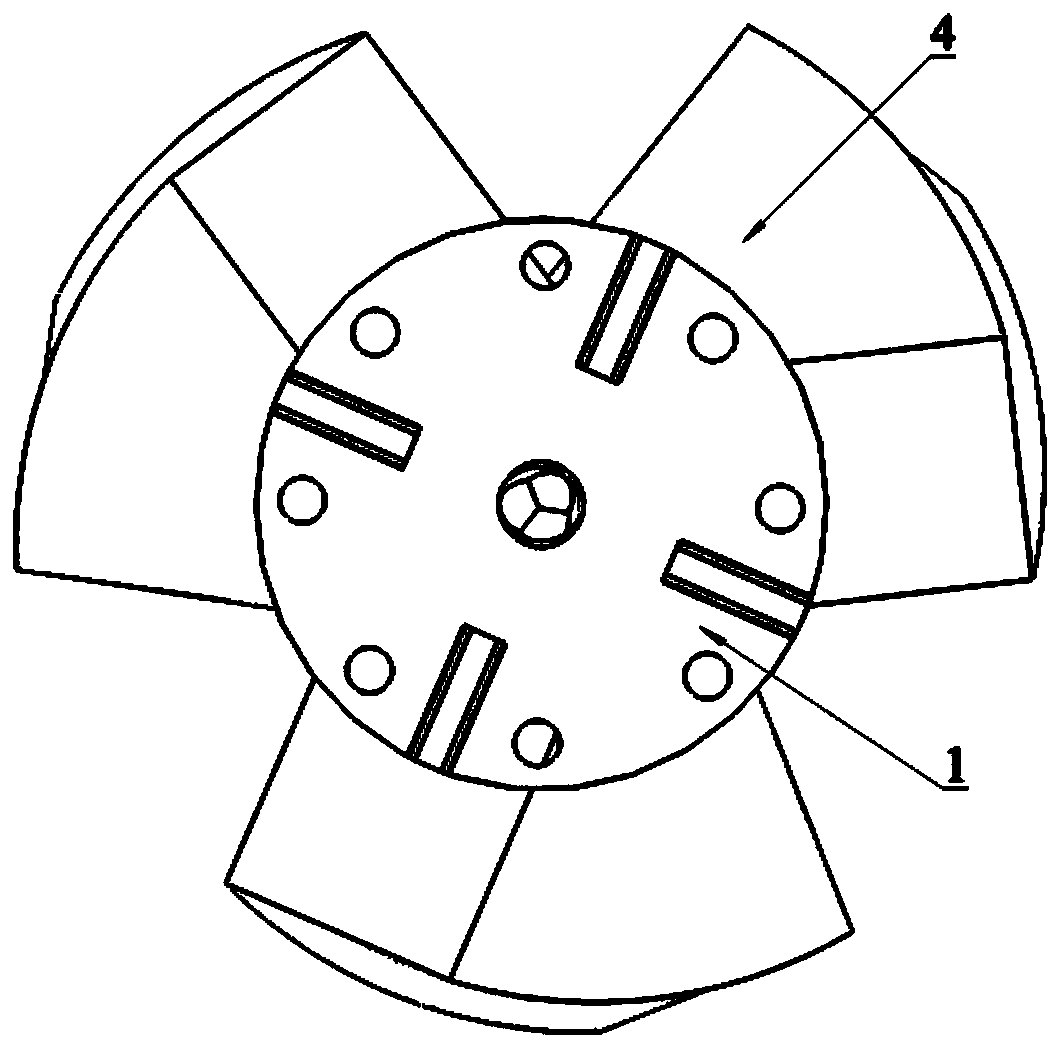

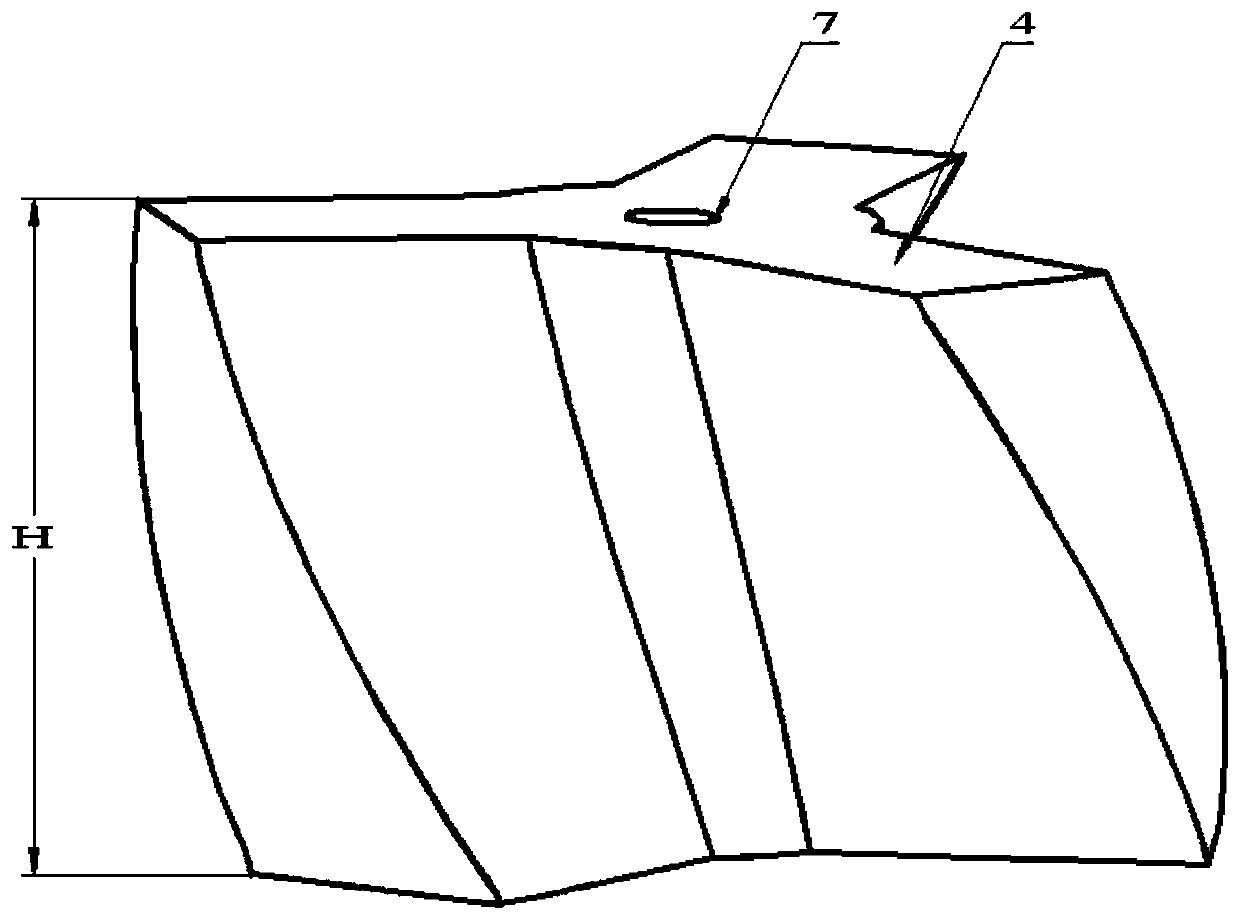

[0044] Stirring blade 4 adopts three helical stirring blades to be evenly arranged around the circumference of the stirring shaft. The angle α of the stirring blade facing the iron surface is 3°, and the radial inclination angle of the stirring blade from bottom to top is 1.5°. Each stirring blade The reverse torsion angle γ is 60°; three small blowing conduits are used at the stirring and blowing head, the diameter of the straight blowing pipe 7 is 25mm, and the diameter of the small blowing conduit is 15mm, and any small blowing conduit 8 and The angle δ of the central axis is 45°, and the other contents are exactly the same as those described above.

Embodiment 2

[0046] The stirring blade 4 adopts four helical stirring blades that are evenly arranged around the circumference of the stirring shaft. The angle α of the stirring blade facing the iron surface is 1.5°, and the radial inclination β angle of the stirring blade from bottom to top is 0.75°. Each stirring blade The reverse torsion angle γ is 30°; four small blowing conduits are used at the stirring and blowing head, the diameter of the straight blowing pipe 7 is 25mm, and the diameter of the small blowing conduit is 10mm, and any small blowing conduit is connected to the center The angle δ of the axis is 60°, and the other contents are exactly the same as those described above.

[0047] The invention provides an injection-type spiral agitator for molten iron desulfurization. During the injection process, the high-pressure power gas carries the desulfurization particles through the straight-through injection pipe, and then sprays them evenly into the molten iron through multiple co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com