Preparation method of modified biomass iron ore sintering additive

A technology for sintering additives and biomass, which is applied to the preparation of modified biomass iron ore sintering additives and the preparation of biomass additives, can solve the problems of complex process flow, small applicable fields, and improvement, and achieve high temperature retention time. , the effect of reducing SOx emissions and optimizing mass transfer conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of modified biomass iron ore sintering additive, the specific method comprises the following steps:

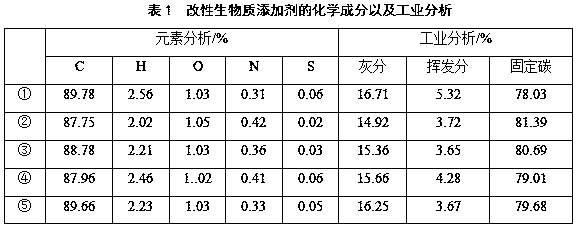

[0029] (1) After natural drying of straw, upgraded coal powder, bamboo materials, activated carbon and ginkgo leaves, crush to a particle size of about 0.3-0.5mm, and the moisture content is not higher than 3%. Then mix thoroughly according to the proportion.

[0030] (2) Place the biomass material mixed in step (1) in an industrial microwave for modification treatment; the treatment process parameters are microwave power of 0W, 200W, 300W, 400W and 500W, and the modification treatment time is 10min.

[0031] (3) Configure Ca 2+ Mother liquor: the mother liquor configured in this embodiment is Ca 2+ hydrochloride solution, weighed CaCl 2 350g powder reagent, mixed with 1000g pure water for blending and stirring, add a certain amount of CaO powder, check the pH of the mother liquor with pH test paper, so that the CaO in the prepared mother liquor ...

Embodiment 2

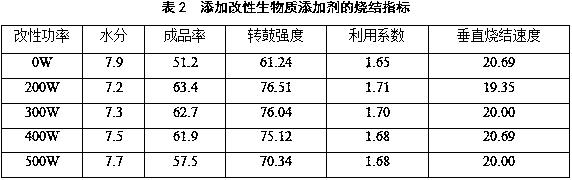

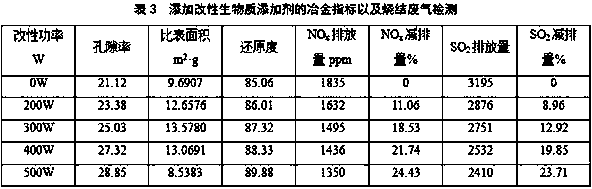

[0037] The mass batching method is used for batching, according to sintered ore TFe57%, SiO 2 4.82%, MgO2.0%, and alkalinity of 2.0 ore blending require ore blending, adding modified biomass additives with a ratio of 0.15%, sintering the blended iron ore mixture, and sintering each Item indicators are shown in Table 2. The metallurgical indicators and sintering waste gas detection results of adding modified biomass additives are shown in Table 3.

[0038] The finished product rate of sintered ore refers to the ratio of finished sintered ore to the total amount of sintered ore. The high yield of sintered ore affects the actual sintering productivity, and also affects the cost reduction and efficiency increase of sintering production and energy saving and emission reduction.

[0039]The higher the strength of the sintering drum, the less pulverized it is, and the better the air permeability in the blast furnace. To a certain extent, the better the drum index, the better the qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com