Desulfurization spraying gun

A desulfurization spray gun and spray gun technology, applied in the field of rotary multi-stage magnesium spraying desulfurization spray gun, can solve the problems of low utilization rate of magnesium and achieve the effects of improving utilization rate, improving dynamic conditions, and improving dynamic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

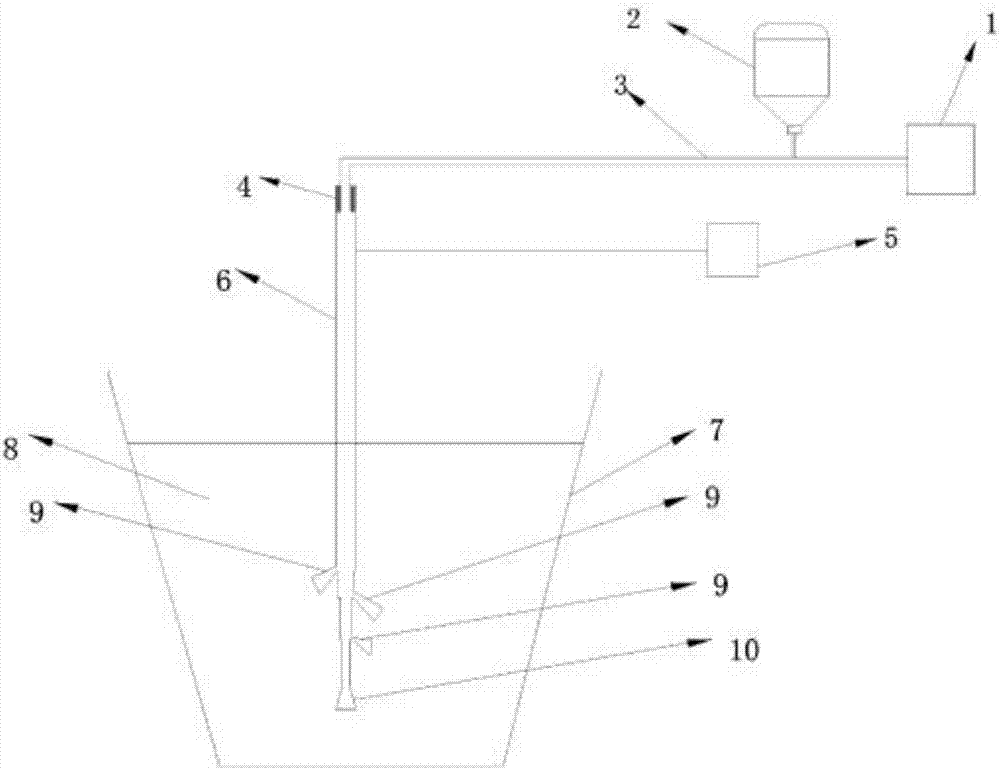

[0034] Such as figure 1 , figure 2 , image 3 As shown in the rotary multi-stage magnesium spraying desulfurization gun, the gun body 6 of the rotary multi-stage magnesium spraying desulfurization gun is connected to the nitrogen gas storage source 1 and the passivated magnesium storage tank 2 through the blowing hose 3, and the spray gun body 6 is connected to the The blowing hose 3 is connected through the sealed bearing 4, and the spray gun body 6 is also connected with the transmission mechanism 5. During the magnesium spray desulfurization process, the transmission mechanism 5 drives the rotary multi-stage magnesium spray desulfurization gun to perform spin motion.

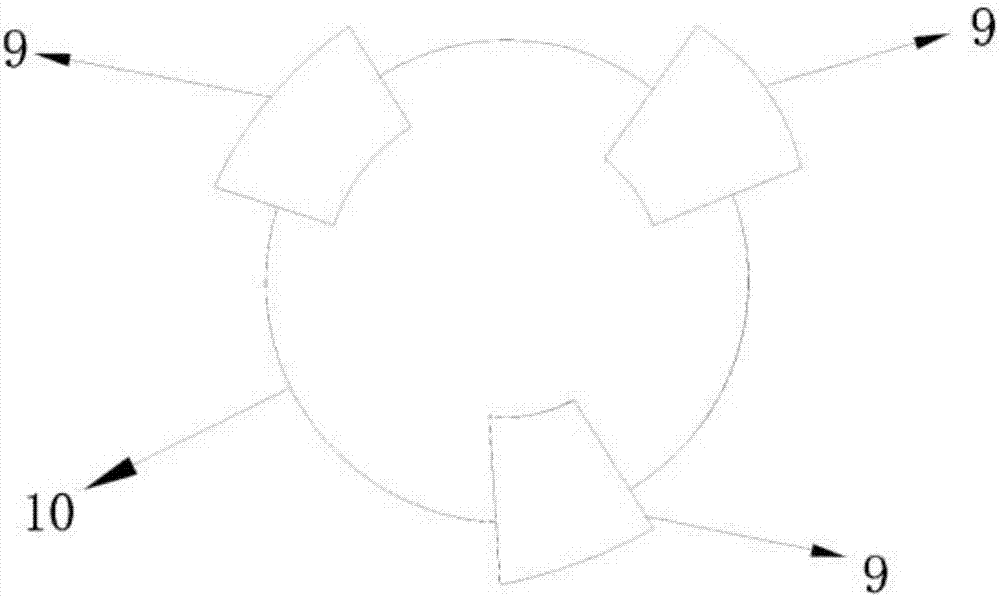

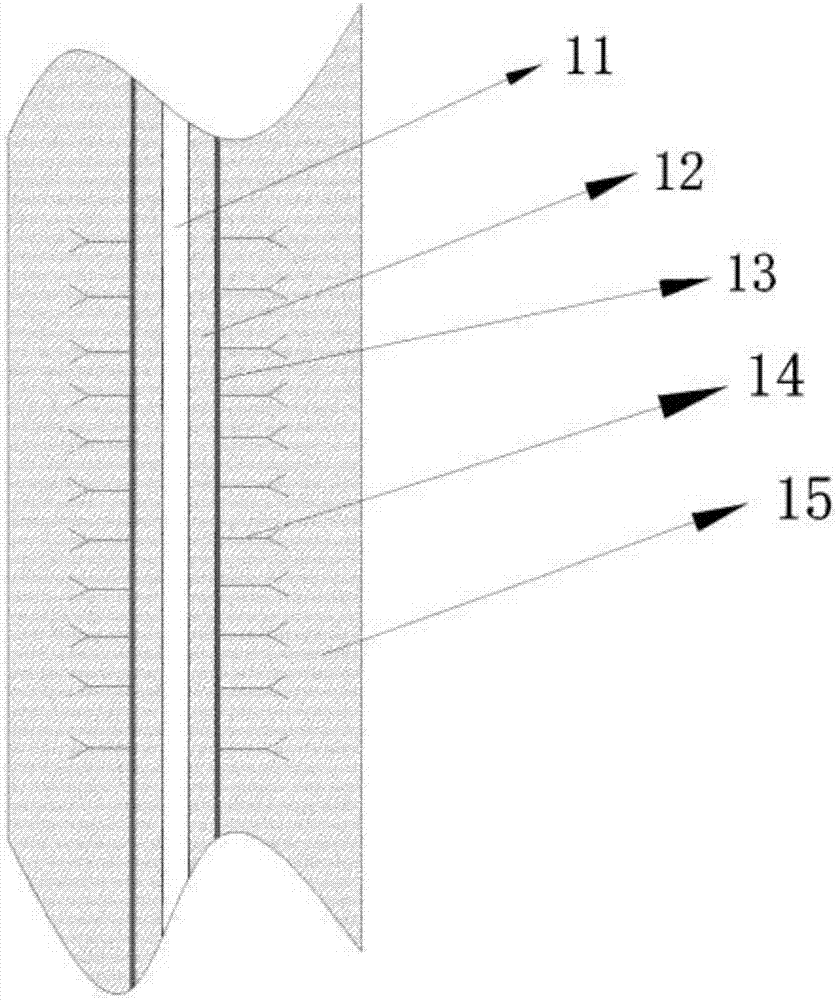

[0035] The outer diameter of the magnesium-spraying desulfurization gun is 350 mm, the inner diameter of the injection channel 11 inside the magnesium-spraying desulfurization gun is 15 mm, the nozzle at the bottom of the magnesium-spraying desulfurization gun is the main nozzle 10, which is in the shape of...

Embodiment 2

[0040] processed as figure 1 , figure 2 , image 3 As shown in the rotary multi-stage magnesium spraying desulfurization gun, the gun body 6 of the rotary multi-stage magnesium spraying desulfurization gun is connected to the nitrogen gas storage source 1 and the passivated magnesium storage tank 2 through the blowing hose 3, and the spray gun body 6 is connected to the The blowing hose 3 is connected through the sealed bearing 4, and the spray gun body 6 is also connected with the transmission mechanism 5. During the magnesium spray desulfurization process, the transmission mechanism 5 drives the rotary multi-stage magnesium spray desulfurization gun to perform spin motion.

[0041] The outer diameter of the magnesium-spraying desulfurization gun is 400mm, the inner diameter of the injection channel 11 inside the magnesium-spraying desulfurization gun is 20mm, the nozzle at the bottom of the spray gun is the main nozzle 10, which is in the shape of a trumpet, and except for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com