Anti-overflow structure for plastic spray head of emulsion pump

A lotion pump and nozzle technology, which is applied in the field of lotion pumps, can solve problems such as looseness and detachment of the nozzle and lotion pump, poor consumer experience, and lotion overflow, so as to reduce the waste of lotion, reduce the probability of occurrence, and improve the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

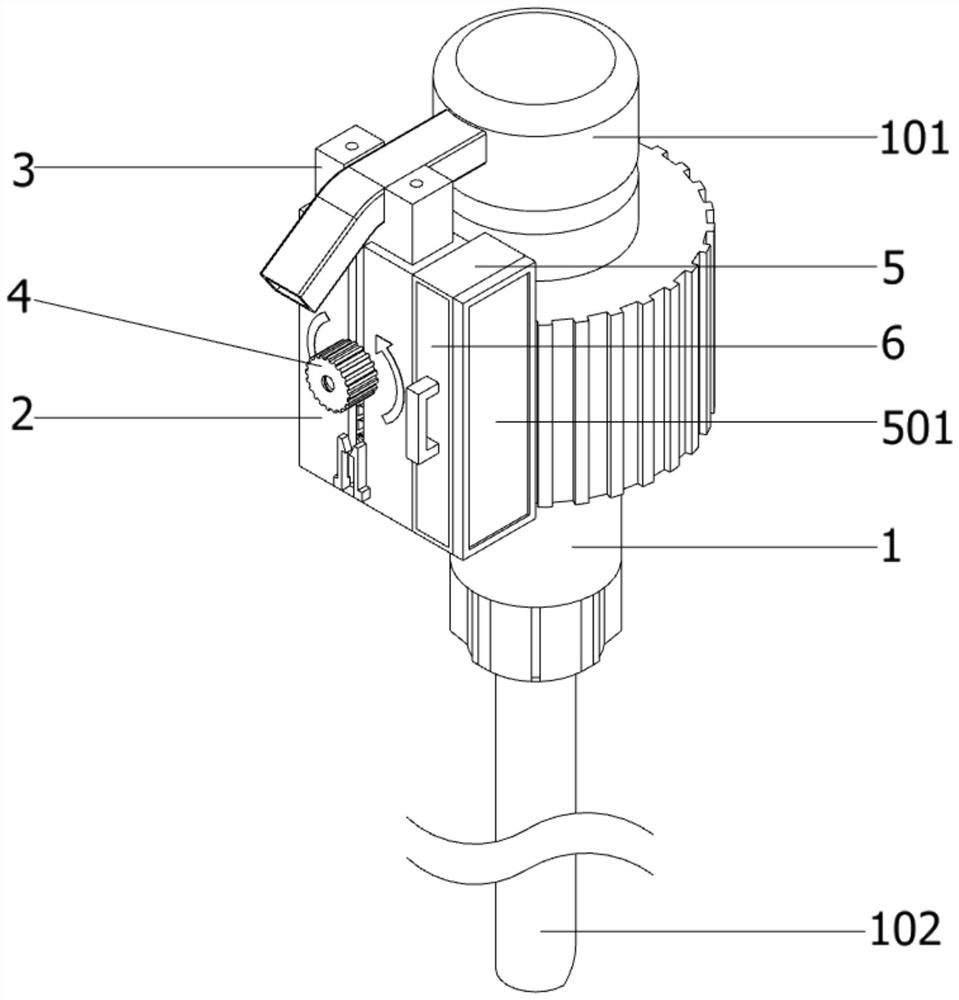

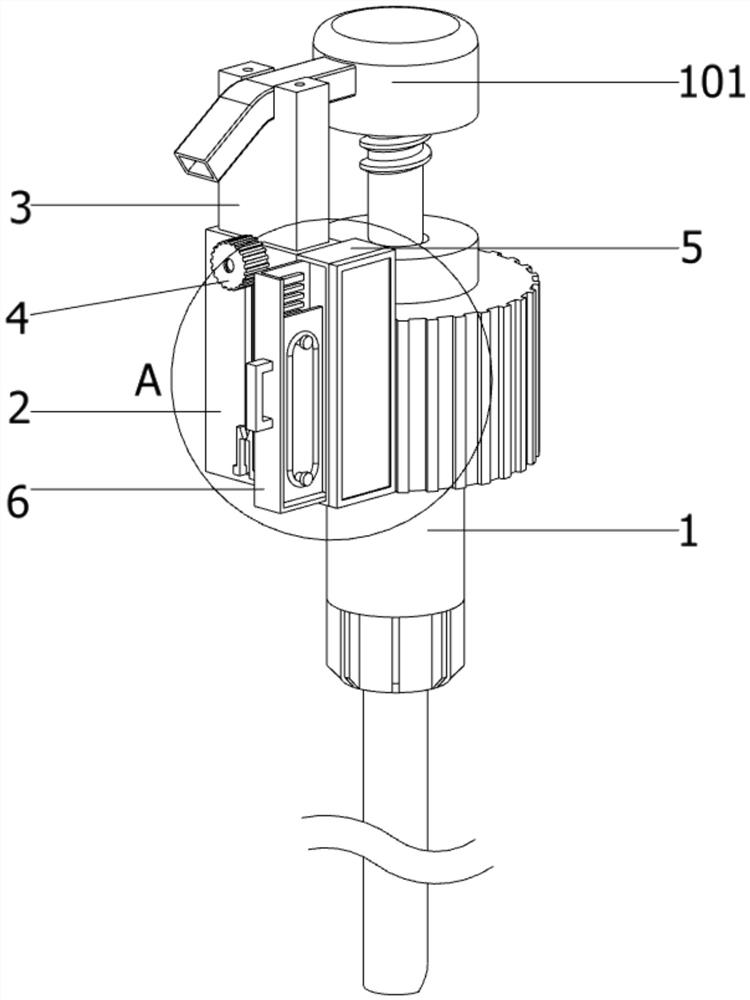

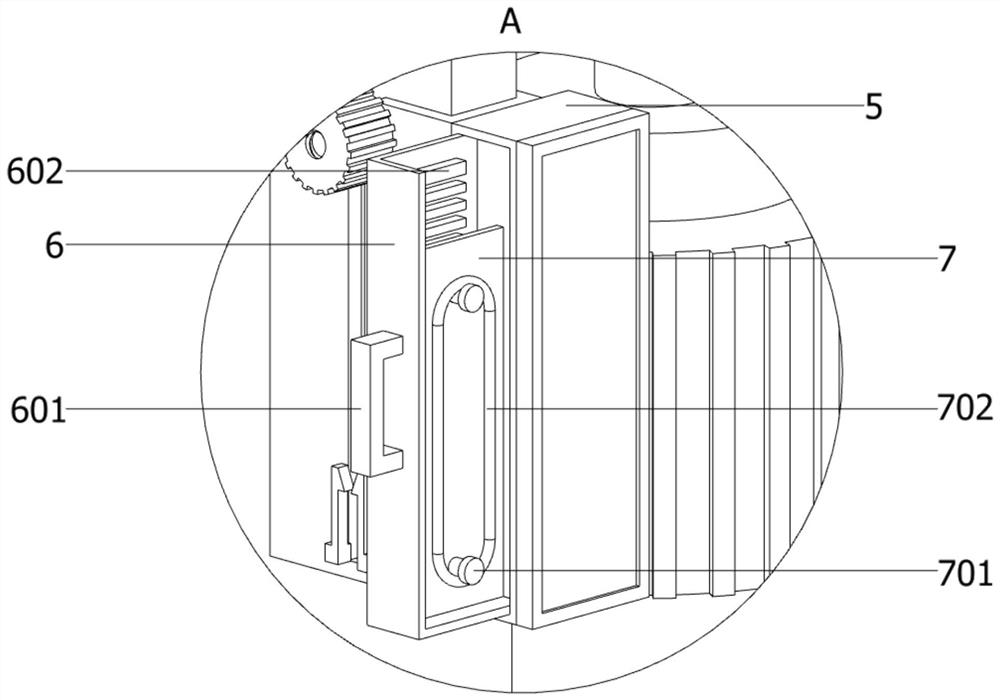

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The present invention provides an anti-spill structure for plastic nozzles of lotion pumps, including a pump body 1, a rectangular chute 2 is arranged on the upper front side of the pump body 1, and the rectangular chute 2 also includes a rectangular opening 201 and an elastic block 202 , sliding column 203, spring 204 and rotation indicator arrow 205, the middle part of the front end of the rectangular chute 2 is provided with a rectangular opening 201, so that the stud 302 will not be hindered when sliding up and down, and the bottom of the front end of the rectangular chute 2 is left-right symmetrical There are two elastic blocks 202, as attached Figure 4 As shown, through the setting of the elastic clamping block 202, people do not need to pull down the concave slider 3 all the time when pulling down the concave slider 3, which improves the convenience when the nozzle 101 is separated from the concave slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com