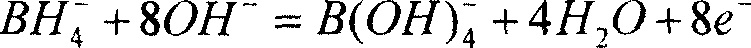

Method for using three-dimensional electrode as direct anode of hydroboron fuel cell

A borohydride electricity and borohydride technology, applied in the parts of fuel cells, fuel cells, battery electrodes, etc., can solve the problems of serious polarization, small anode reaction area, small battery output power, etc. Differential polarization, simple preparation method, and high battery output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

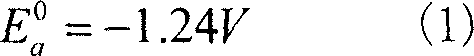

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024] Take a copper mesh with a length and width of 1cm and a hole diameter of 3mm and soak it in dilute sulfuric acid for half an hour, then rinse it with distilled water, and then soak it in ethanol for 1 hour, then polish it with coarse sandpaper and fine sandpaper in turn, and wash it with distilled water Rinse and wipe clean with filter paper; take three pieces of the above-mentioned copper mesh, stack them together, and assemble them into a packed bed. The copper mesh electrode is used as the anode of the direct borohydride fuel cell, and the carbon rod is used as the cathode, and placed in a closed electrochemical reaction tank , separated by a cation exchange membrane in the middle, and the electrolyte on the anode side consists of 2.0mol L -1 NaBH 4 with 2.5mol·L -1 The solution composed of NaOH adopts a through-flow feeding method parallel to the direction of the current, and the flow rate is 5ml min -1 ; Cathode side electrolyte is 2.5mol L -1 NaOH, the oxidant ...

Embodiment approach 2

[0026]Soak a copper plate with a thickness of 3mm in dilute sulfuric acid for half an hour, then rinse it with distilled water, then soak it in ethanol for 1 hour, then polish it with coarse sandpaper and fine sandpaper in turn, rinse it with distilled water, and wipe it clean with filter paper; Get the three above-mentioned copper plates whose length and width are each 1cm, stack them together, keep the distance of 5mm between each copper plate, assemble into a packed bed copper plate electrode as the anode of the direct borohydride fuel cell, and the porous carbon rod as the cathode, Put it into a closed electrochemical reaction tank, separated by an anion exchange membrane in the middle, and the electrolyte on the anode side is composed of 2.0mol L -1 NaBH4 and 1.0mol·L -1 The solution composed of NaOH adopts a through-flow feeding method perpendicular to the direction of the current, and the flow rate is 3ml min -1 ; Cathode side electrolyte is 3.0mol L -1 NaOH, the oxid...

Embodiment approach 3

[0028] Take a nickel mesh with a length and width of 1cm and a hole diameter of 3mm and soak it in dilute sulfuric acid for half an hour, then rinse it with distilled water, and then soak it in ethanol for 1 hour, then polish it with coarse sandpaper and fine sandpaper in turn, and then use distilled water to polish it. Rinse and wipe clean with filter paper; take three pieces of the above-mentioned nickel mesh, stack them together, and assemble them into a packed bed. The nickel mesh electrode is used as the anode of the direct borohydride fuel cell, and the carbon rod is used as the cathode, and placed in a closed electrochemical reaction tank , separated by a cation exchange membrane in the middle, and the electrolyte on the anode side consists of 0.005mol L -1 KBH4 and 5.0mol L -1 The solution composed of KOH adopts a through-flow feeding method perpendicular to the direction of the current, and the flow rate is 5ml min -1 ; Cathode side electrolyte is 5.0mol L -1 KOH, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com