Preparation method of carbon nanotube composite wire

A carbon nanotube composite and carbon nanotube fiber technology, which is used in the equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, electrical components, etc., can solve the problem of poor conductivity, low conductivity, and low strength. problems, to achieve the effect of increasing strength and electrical conductivity, improving interfacial bonding force, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

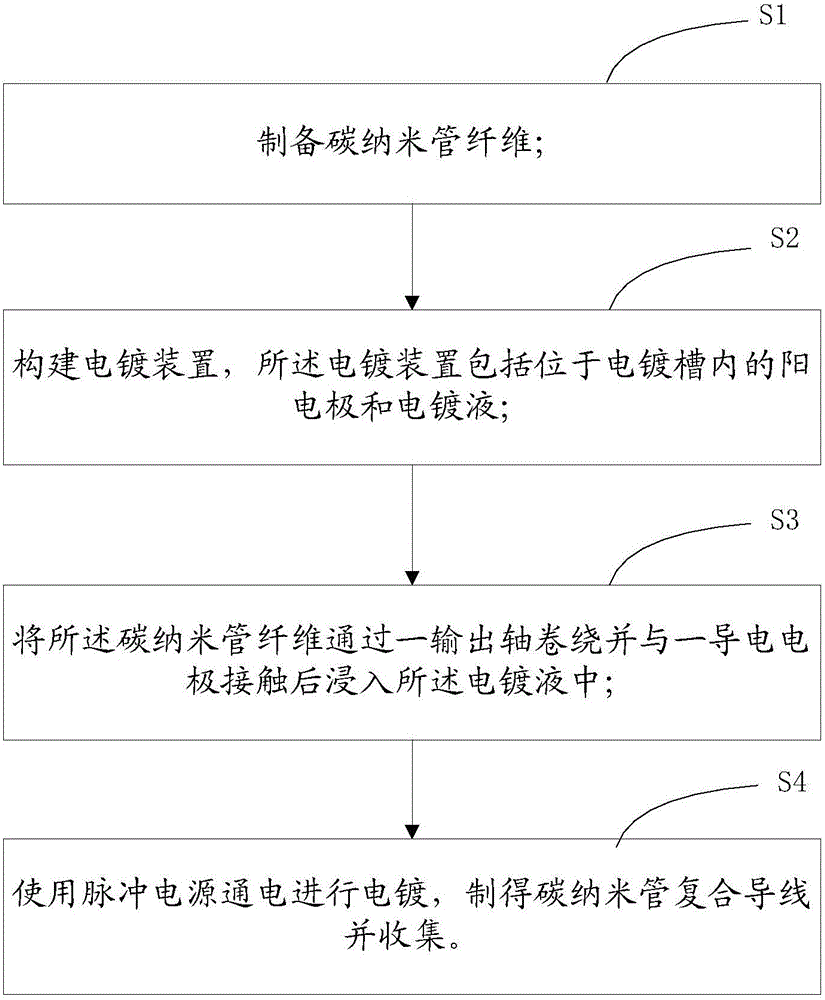

Method used

Image

Examples

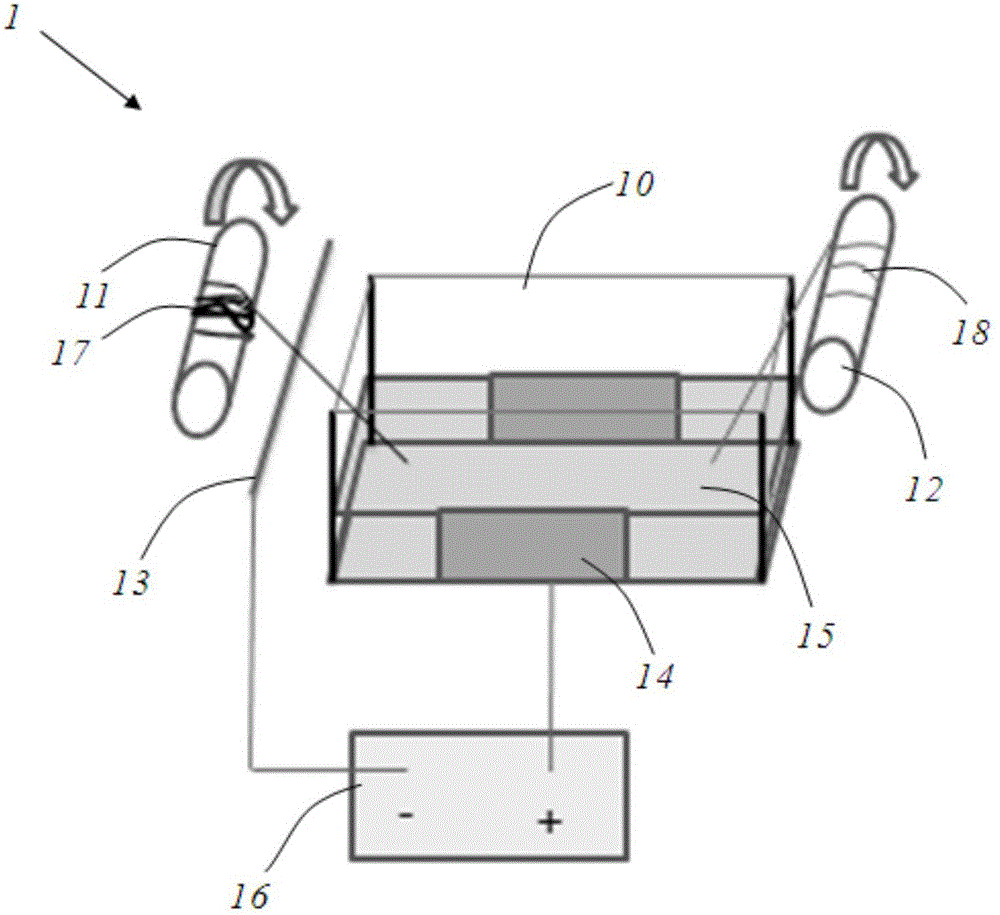

Embodiment 1

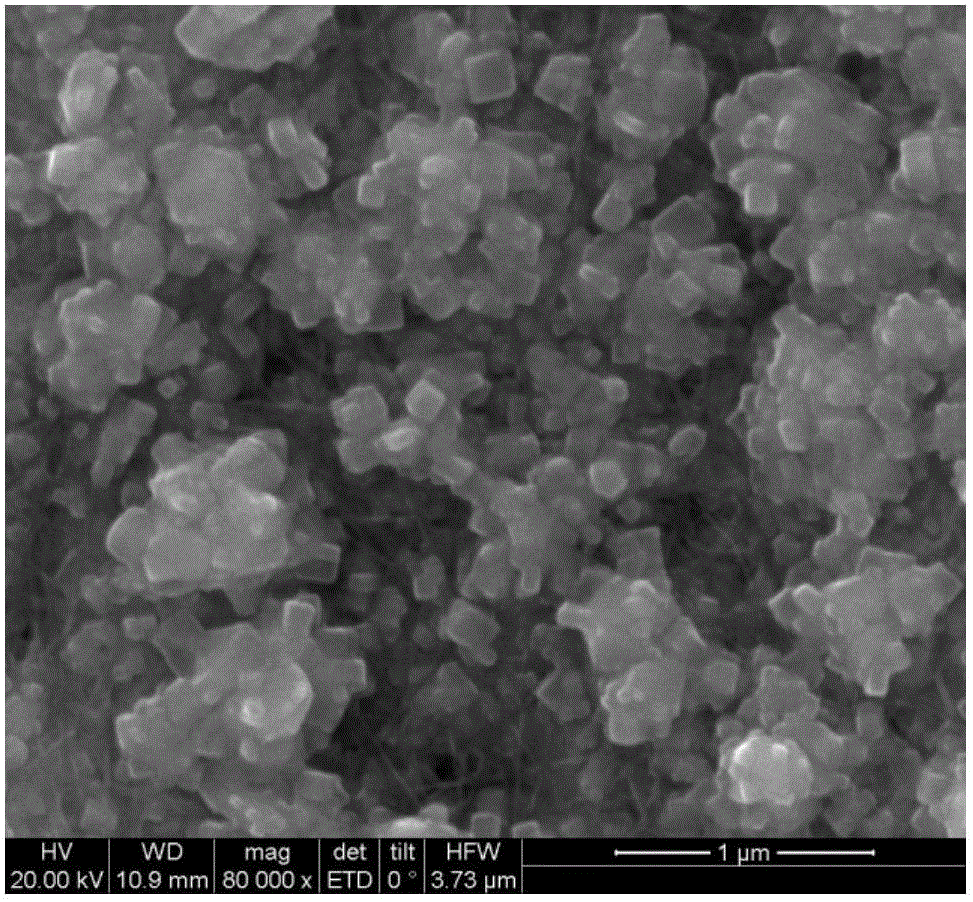

[0042] Select carbon nanotube fibers with a diameter of 100 microns and wind them on the output shaft 11. One end of the carbon nanotube fibers is released from the output shaft 11, and after being in contact with the conductive electrode 13, it is immersed in the electroplating solution 15 to stretch the carbon nanotubes. Fiber and its collection shaft 12, the rotating speed of setting collection shaft and output shaft is 5r / min. The concentration of copper sulfate pentahydrate in the electroplating solution is 120g / L, the concentration of sulfuric acid is 0.1mol / L, the temperature of the electroplating solution is kept at 25°C, and the electroplating is performed by using a pulse power supply with a current density of 0.01A / cm 2 , pulse width 0.25s ( Figure 6a ), the pulse interval is 2s, and the current disconnection time is 2s, and the carbon nanotube composite wire 18 is prepared. Its fiber cross-section is as Figure 6b As shown, it can be clearly seen that there are ...

Embodiment 2

[0044] Select carbon nanotube fibers with a diameter of 30 microns and wind them on the output shaft 11. One end of the carbon nanotube fibers is released from the output shaft 11, and after being in contact with the conductive electrode 13, it is immersed in the electroplating solution 15 to stretch the carbon nanotubes. Fiber and its collection shaft 12, the rotating speed of setting collection shaft and output shaft is 5r / min. The concentration of copper sulfate pentahydrate in the electroplating solution is 140g / L, the concentration of sulfuric acid is 0.1mol / L, the temperature of the electroplating solution is kept at 25°C, and the electroplating is performed by using a pulse power supply with a current density of 1A / cm 2 , pulse width 0.05s ( Figure 7a ), the pulse interval is 2s, and the current disconnection time is 2s, and the carbon nanotube composite wire 18 is prepared. Its fiber cross-section is as Figure 7b As shown, it can be clearly seen that there are copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com