Steel strip plated with multi-layer micron/nano-crystal nickel films and preparation method thereof

A multi-layer film and nanocrystalline technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of insufficient attention to the stamping performance of steel strips, reduced corrosion resistance, and high production costs. To achieve the effect of reducing the possibility of surface scratches, reducing porosity, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

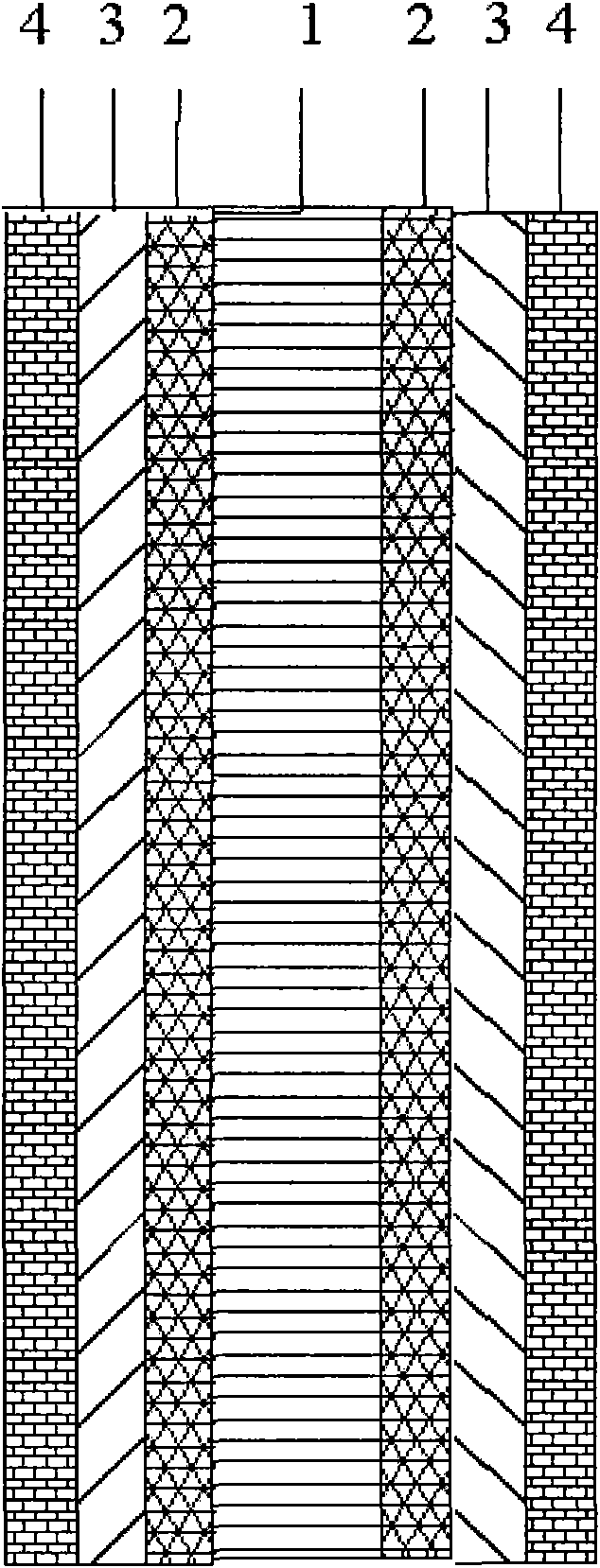

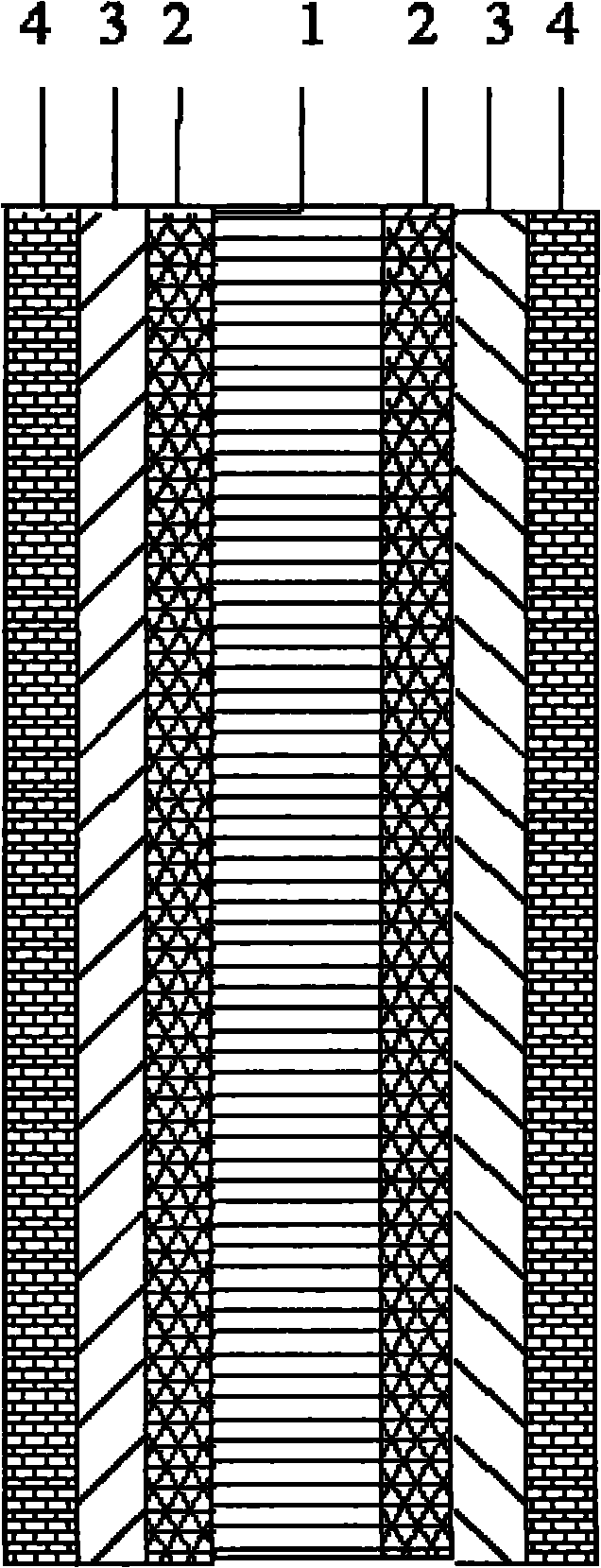

[0070] A steel strip coated with a micro / nanocrystalline nickel multilayer film of the present invention uses the steel strip as the base 1, and the two sides of the base 1 are respectively coated with a micro / nanocrystalline nickel multilayer film; the micro / nano The bottom layer 2 of the crystalline nickel multilayer film is a microcrystalline nickel coating with a grain size of 0.1-0.5 μm and a thickness of 0.5-2.0 μm; the middle layer 3 is a nano-crystalline nickel coating with a grain size of 50-100 nm and a thickness of 0.5-1.5 μm ; The surface layer 4 is a nanocrystalline nickel coating with a grain size of 20-50 nm and a thickness of 0.2-1 μm. Such as figure 1 shown.

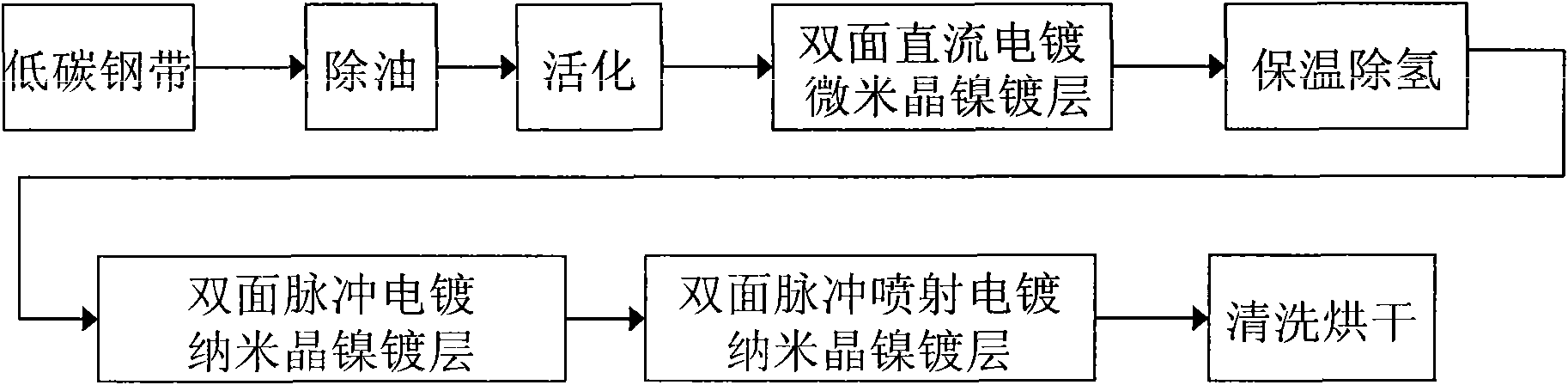

[0071] Technical process of the present invention sees figure 2 .

[0072] The special steel strip for BDCK batteries with a thickness of 0.25 mm produced by Shanghai Baoshan Iron and Steel Co., Ltd. was selected as the electroplating substrate.

[0073] Its chemical composition is: C: 0.029% (% mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com