Cyanide-free alkaline copper plating method for improving impermeable carbon copper film

A cyanide-free alkaline copper plating and carbon-copper film technology, applied in the field of technology, can solve the problems of impurity precipitation, hydrogen embrittlement, and the easy dissolution of single anode degreasing parts, so as to increase the bonding strength, improve the growth of mold, and reduce the The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

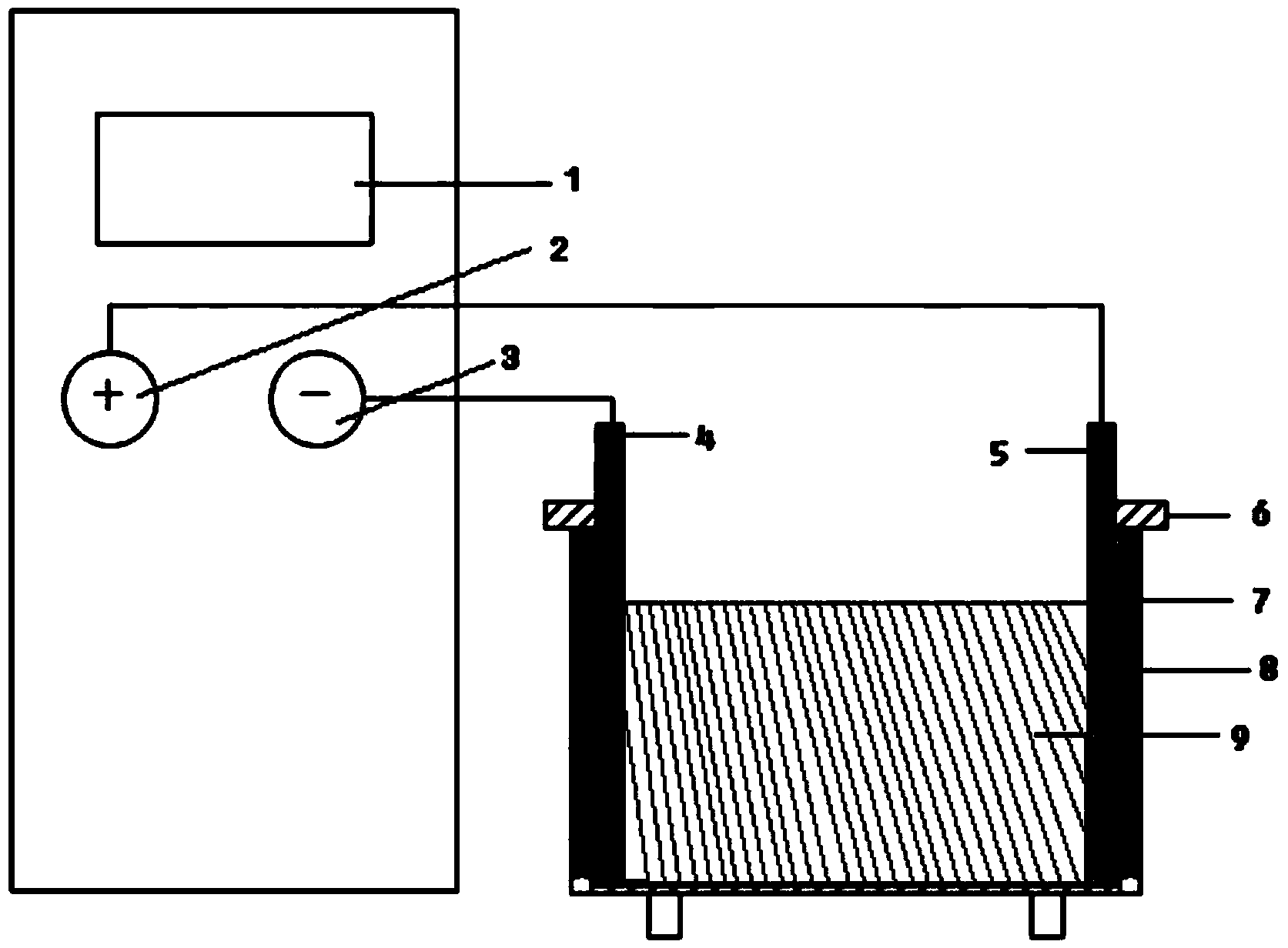

[0022] Specific implementation mode one: a kind of preparation method of the cyanide-free alkaline copper plating of improving anti-carburization copper film of this embodiment comprises the following steps:

[0023] 1. Electrochemical method to remove oil and dirt on the surface of the workpiece: place the workpiece to be treated in an electrochemical degreasing solution with a temperature of 60 ° C to 75 ° C, and use a pulse power supply for electrolytic degreasing;

[0024] Among them, the electrolytic degreasing conditions are as follows: the cathode current density is 6-8A / dm 2 , the pulse period is 0.02s~0.002s, the anode current density is 6~8A / dm 2 , the pulse period is 0.02s ~ 0.002s, the number ratio of cathode and anode pulses (3 ~ 10): 1;

[0025] The proportion of the electrochemical degreasing solution is as follows: each 1L solution contains a sodium hydroxide solution with a concentration of 15-25g / L, a sodium carbonate solution with a concentration of 20-30g / ...

specific Embodiment approach 2

[0035] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the electrolytic degreasing conditions described in step one are as follows: the cathode current density is 7A / dm 2 , the pulse period is 0.02s~0.01s, the anode current density is 7A / dm 2 , the pulse period is 0.02s ~ 0.01s, the number ratio of cathode and anode pulses (5 ~ 7): 1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the electrochemical degreasing solution described in step 1 is formulated as follows: every 1 L of solution contains sodium hydroxide with a concentration of 20-25 g / L Solution, sodium carbonate solution with a concentration of 25-30g / L and trisodium phosphate solution with a concentration of 15-20g / L. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com