Solar battery coating equipment and coating method

A technology for solar cells and coating equipment, which is applied in the manufacture of circuits, electrical components, and final products. It can solve the problems of electroplating grid stripping, low nucleation density of metal films, and lack of timely replenishment of electroplating cations, etc., to reduce resistance, The effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] The purpose and effects of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

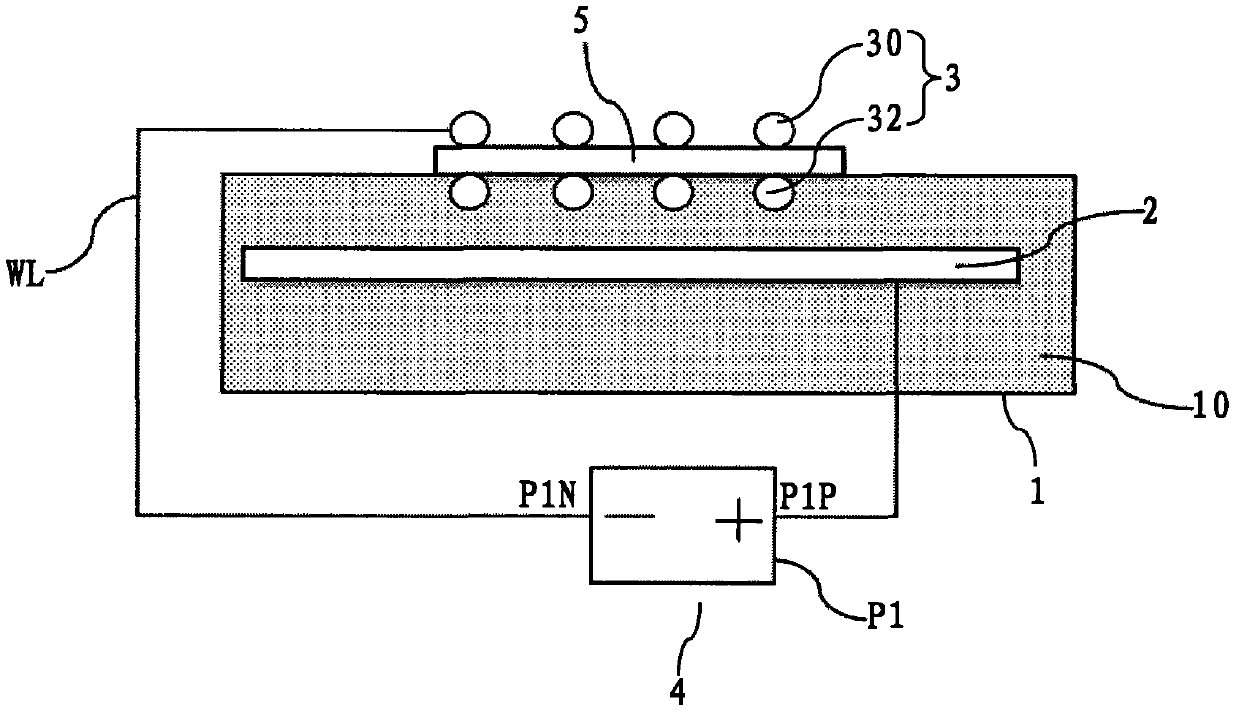

[0031] see figure 2 , which shows a schematic diagram of the composition and structure of the first embodiment of the solar cell coating equipment of the present invention, the solar cell coating equipment includes a coating tank 1, a metal rod 2, a solar cell transmission module 3 to be coated and a pulse excitation source 4. The solar cell coating equipment is used to coat the area to be coated on the light-receiving surface of the solar cell 5 to be coated, that is, the electrode area. The negative electrode and the positive electrode of the solar cell are respectively arranged on the light-receiving surface and the backlight surface of the solar cell 5 to be coated. In this embodiment, the pulse excitation source 4 is a pulse power supply P1.

[0032] In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com