Through hole pulse electroplating solution and through hole pulse electroplating coating method

A technology of pulse electroplating and electroplating solution, which is applied to the formation of electrical connections of electrodes and printed components, etc. It can solve the problems of reducing factory production efficiency and increasing the cost of raw materials-copper, so as to reduce workload, increase organic matter consumption, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

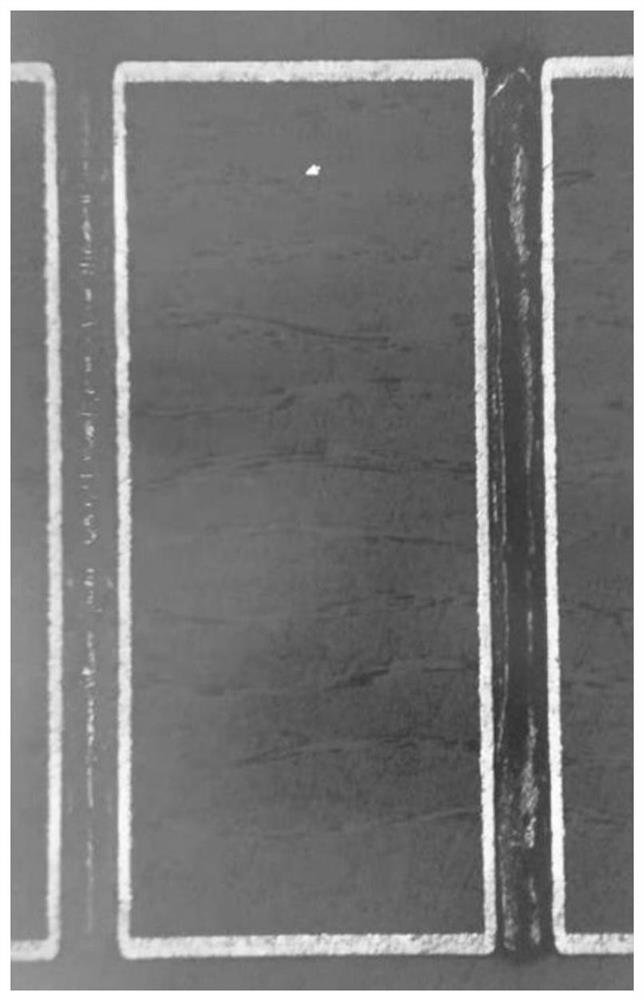

[0039] Copper plating is performed on an epoxy resin substrate with a through hole diameter of 0.2mm, a thickness of 1.6mm, and an aspect ratio of 8:1.

[0040] Composition of copper sulfate plating solution:

[0041] Copper sulfate pentahydrate: 70g / L;

[0042] Sulfuric acid (mass fraction 98%): 230g / L;

[0043] Chloride ion: 70mg / L (added by 37% hydrochloric acid);

[0044] Wetting agent: The wetting agent contains ethylene oxide / propylene oxide copolymer and polyethylene glycol, among which the ethylene oxide and propylene oxide copolymer is BASF Pluronic PE6100 with a content of 500mg / L; polyethylene glycol Select polyethylene glycol 8000 for use, and the content is 500mg / L;

[0045] Brightener: sodium dithiopropane sulfonate, 3mg / L;

[0046] Heptahydrate ferrous sulfate: 50g / L;

[0047] Fe(III): 1.3g / L.

[0048] Plating conditions:

[0049] Bath temperature: 25°C;

[0050] Cathode current density: 3A / dm 2 ;

[0051] Plating time 60min;

[0052]

[0053] Stir...

Embodiment 2

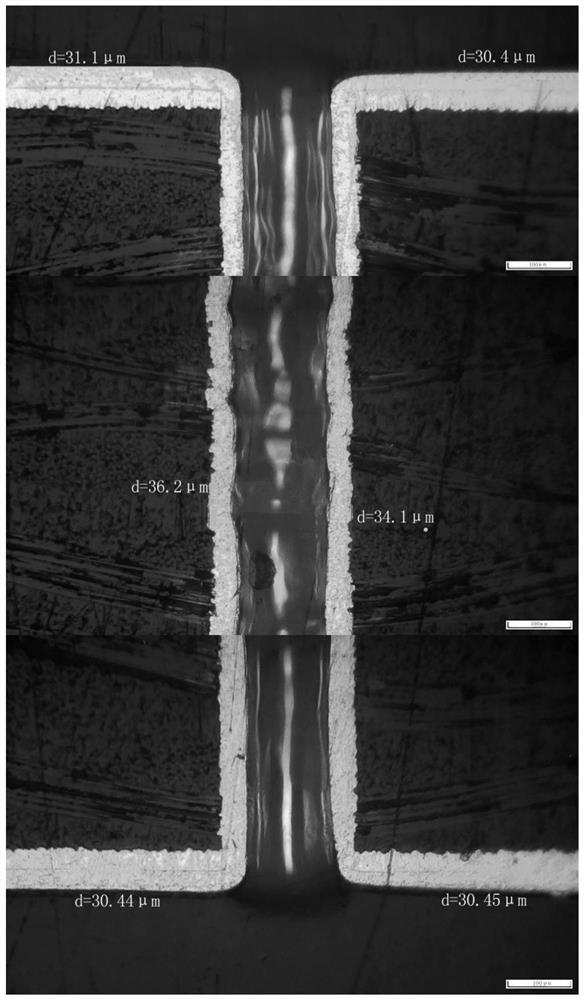

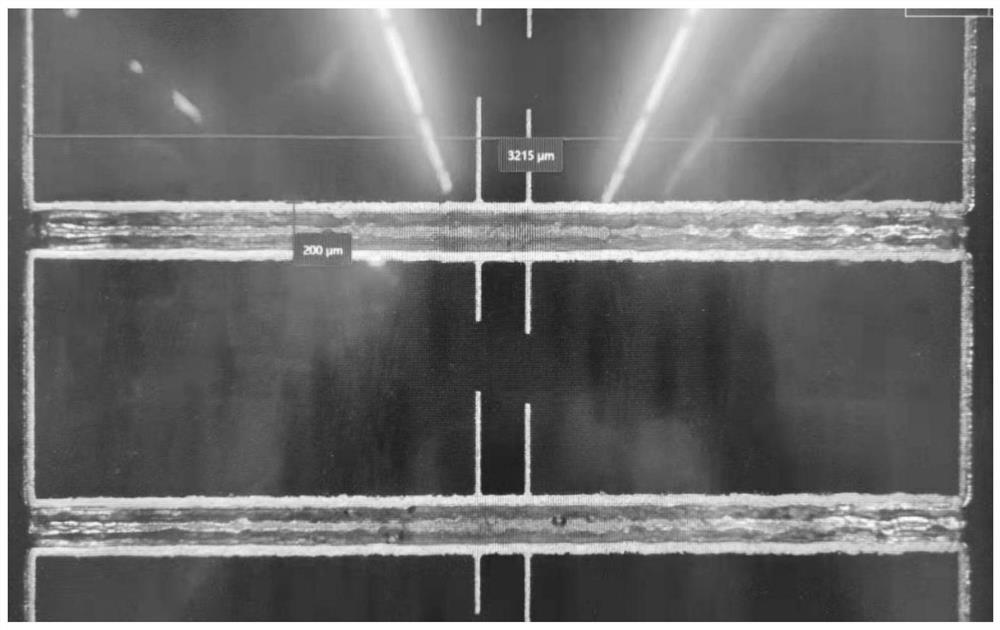

[0056] Copper plating is performed on an epoxy resin substrate with a through hole diameter of 0.2mm, a thickness of 3.2mm, and an aspect ratio of 16:1.

[0057] Composition of copper sulfate plating solution:

[0058] Copper sulfate pentahydrate: 70g / L;

[0059] Sulfuric acid (mass fraction 98%): 230g / L;

[0060] Chloride ion: 70mg / L (added by 37% hydrochloric acid);

[0061] Wetting agent: ethylene oxide / propylene oxide copolymer, Dow Ucon 50HB-2000, 800mg / L;

[0062] Brightener: sodium dithiopropane sulfonate, 2mg / L;

[0063] Heptahydrate ferrous sulfate: 50g / L;

[0064] Fe(III): 1.3g / L.

[0065] Plating conditions:

[0066] Bath temperature: 25°C;

[0067] Cathode current density: 2A / dm 2 ;

[0068] Plating time 90min;

[0069] DC first pulse second pulse third pulse DC Forward current density A / dm 2

[0070] Stirring: jet flow + air stirring.

Embodiment 3

[0072] Copper plating is performed on an epoxy resin substrate with a through hole diameter of 0.2 mm, a thickness of 4.0 mm, and an aspect ratio of 20:1.

[0073] Composition of copper sulfate plating solution:

[0074] Copper sulfate pentahydrate: 70g / L;

[0075] Sulfuric acid: 240g / L;

[0076] Chloride ion: 70mg / L (added by 37% hydrochloric acid);

[0077] Wetting agent: wetting agent includes copolymer and polyethylene glycol, among which the ethylene oxide / propylene oxide copolymer is DowUcon50HB-660, the concentration is 1000mg / L; the polyethylene glycol is polyethylene glycol 20000, the content 500mg / L;

[0078] Brightener: sodium dithiopropane sulfonate: 4mg / L;

[0079] Heptahydrate ferrous sulfate: 50g / L;

[0080] Fe(III): 1.5g / L.

[0081] Plating conditions:

[0082] Bath temperature: 25°C;

[0083] Cathode current density: 1.5 / dm 2 ;

[0084] Plating time 120min;

[0085]

[0086] Stirring: jet flow + air stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com