Thiosulfate cyanide-free gold-plating electroplating liquid with added hydrazine hydrochloride and electroplating method

A technology of thiosulfate and thiosulfate is applied in the field of electroplating copper and tin, which can solve the problems of low quality of coating, poor performance of plating solution, restricting the promotion of cyanide-free gold electroplating, etc., and achieves high brightness and coating quality. Good results with excellent bath performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

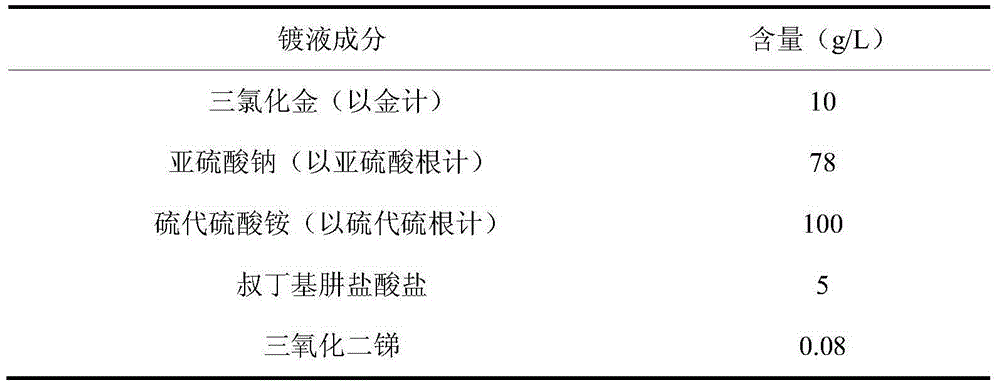

Embodiment 1

[0035] The formulation of the electroplating solution is as follows:

[0036]

[0037] Plating process conditions: the pulse width of single pulse square wave current is 0.5ms, the duty cycle is 30%, and the average current density is 0.5A / dm 2 ; The pH is 6, the temperature is 60°C, and the electroplating time is 40min.

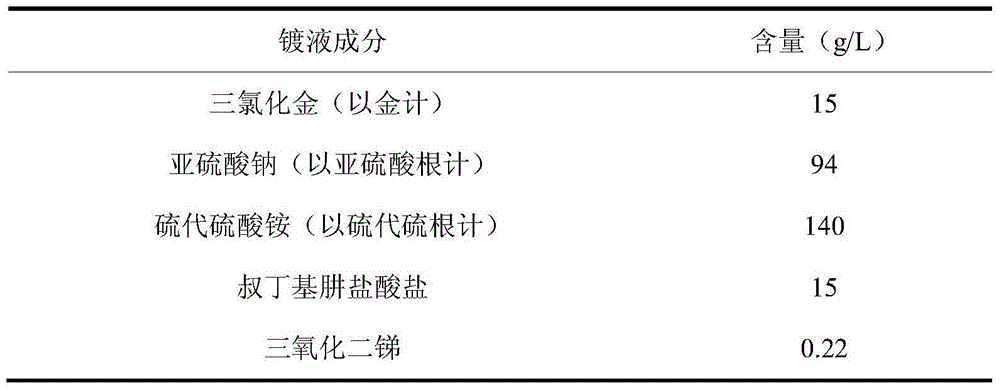

Embodiment 2

[0039] The formulation of the electroplating solution is as follows:

[0040]

[0041] Plating process conditions: the pulse width of single pulse square wave current is 0.6ms, the duty cycle is 25%, and the average current density is 0.6A / dm 2 ; The pH is 6.5, the temperature is 60°C, and the electroplating time is 35min.

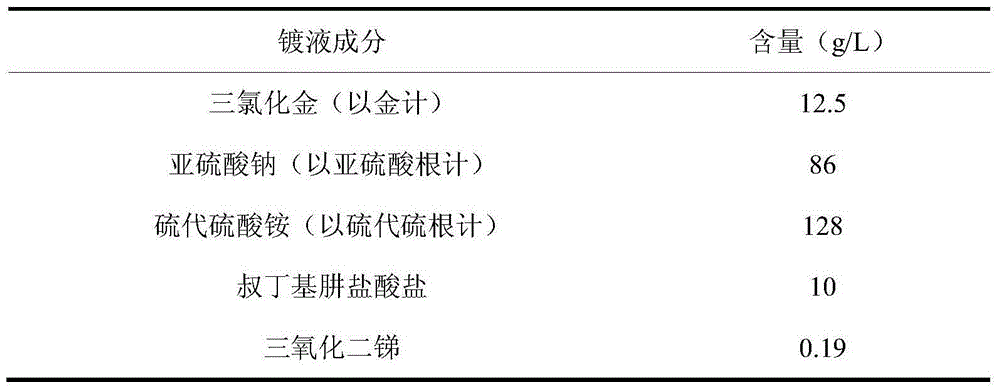

Embodiment 3

[0043] The formulation of the electroplating solution is as follows:

[0044]

[0045] Plating process conditions: the pulse width of single pulse square wave current is 0.8ms, the duty cycle is 20%, and the average current density is 1A / dm 2 ; The pH is 7, the temperature is 50° C., and the electroplating time is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com