Laser pulse electroplating system

A laser pulse and pulse electroplating technology, which is applied in the field of laser pulse electroplating systems, can solve the problems of not being able to obtain a positive square wave, a large degree of waveform distortion, and low frequency, and achieve high-precision controllable deposition, absorption, and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

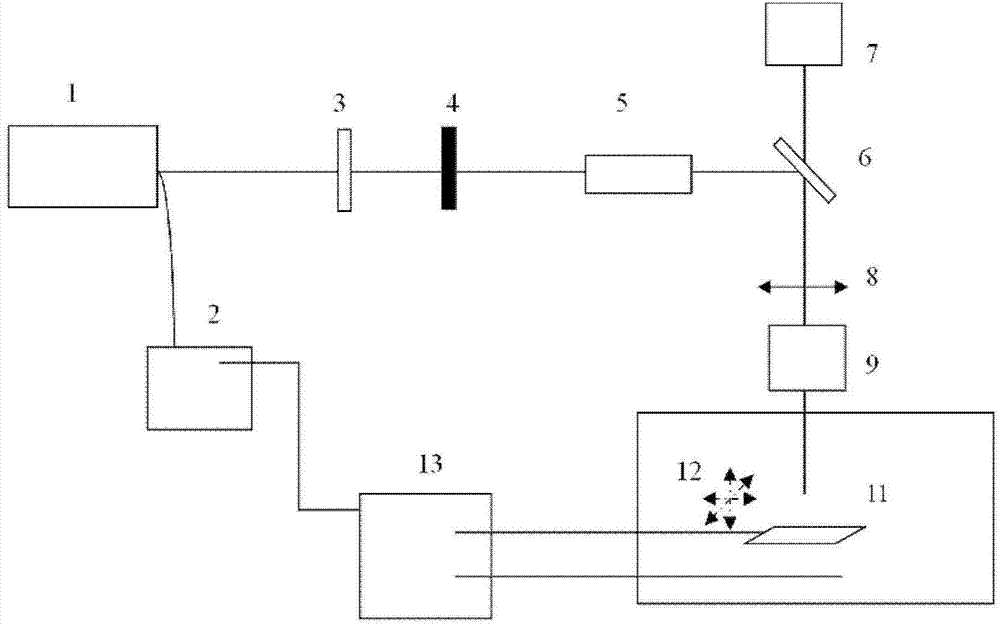

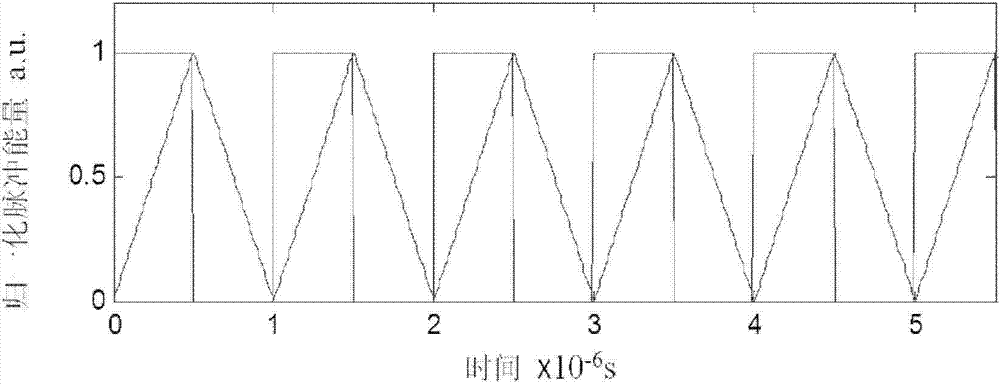

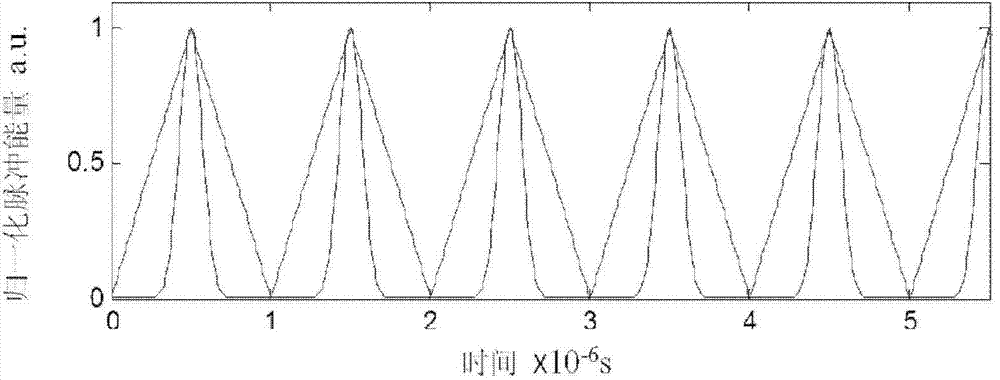

[0040] The following combination figure 1 The specific implementation of the laser pulse electroplating system of the present invention is described in detail: pulse laser 1 is that the laser beam wavelength of Q-switched YAG frequency doubled laser output is 532nm, and average power is 350mW, and pulse width is 100ns, and spot diameter after focusing is 500um, The working frequency is 1MHz; the pulse laser 1 and the pulse electroplating power supply 13 are connected to the pulse generation controller 2, and the pulse laser emitted by the pulse laser 1 and the power pulse sent by the pulse electroplating power supply 13 are controlled to be superimposed by the method of electrical signal modulation, and the instant delay difference is 0. The repetition frequency of the pulsed laser and the pulsed electroplating power supply must be consistent. A schematic comparison of ideal power pulses and actual power pulses is shown in Figure 2(a). Among them, the ideal power pulse (hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com