Method for electroplating Ni-Cr-PTFE composite coating in ionic liquid

A composite coating, ionic liquid technology, used in coatings, electrolytic coatings, etc., can solve the problems that metal coatings cannot meet surface hardness, wear resistance, corrosion resistance, electrical conductivity and self-lubrication, and achieve uniform distribution of PTFE. , The effect of friction reduction and hardness improvement, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments.

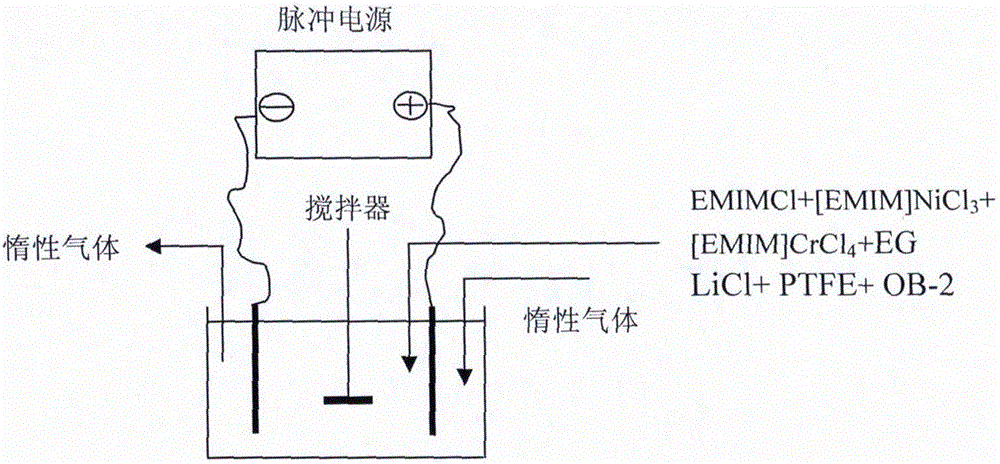

[0015] Step 1. In an inert gas environment, first take 300mL of anhydrous mixed solvent of 1-ethyl-3-methylimidazolium chloride (EMIMCl) and ethylene glycol (EG) with a molar ratio of 1:2 and put it into a self-made electrolytic cell , and then add 16 grams of nickel-containing ionic liquid [EMIM]NiCl to the anhydrous mixed solvent 3 , 18 grams of chromium-containing ionic liquid [EMIM]CrCl 4 , 2gLiCl, 12gPTFE and 6mL of dodecyl dimethyl amine oxide (OB-2), mechanically stirred and ultrasonically stirred for 10h to mix evenly to obtain an electroplating solution;

[0016] Step 2, as attached figure 1 As shown, the copper substrate is subjected to pretreatment processes such as alkaline degreasing, pickling, water washing, and drying as the cathode, and the platinum sheet as the anode. Put the cathode and anode into the electroplating solution obtained in step 1, and keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com