Material for shell of connector and preparation method thereof

A technology for connectors and shells, which is applied in the field of connector shell materials and its preparation, which can solve problems such as corrosion, aluminum substrate corrosion, and coating peeling off during use, so as to reduce surface scratches and improve corrosion resistance. , the effect of smooth surface

Active Publication Date: 2010-09-08

HUNAN YONGSHENG NEW MATERIALS

View PDF7 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, there are many problems in the existing method: Chinese patent CN1564381A mentions that the existing electric connector shell material with nickel plating on the aluminum substrate is not dense in different degrees due to the plating layer of electroplating and chemical plating. Corrosion is prone to occur in the medium, resulting in corrosion of the aluminum substrate, resulting in peeling of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

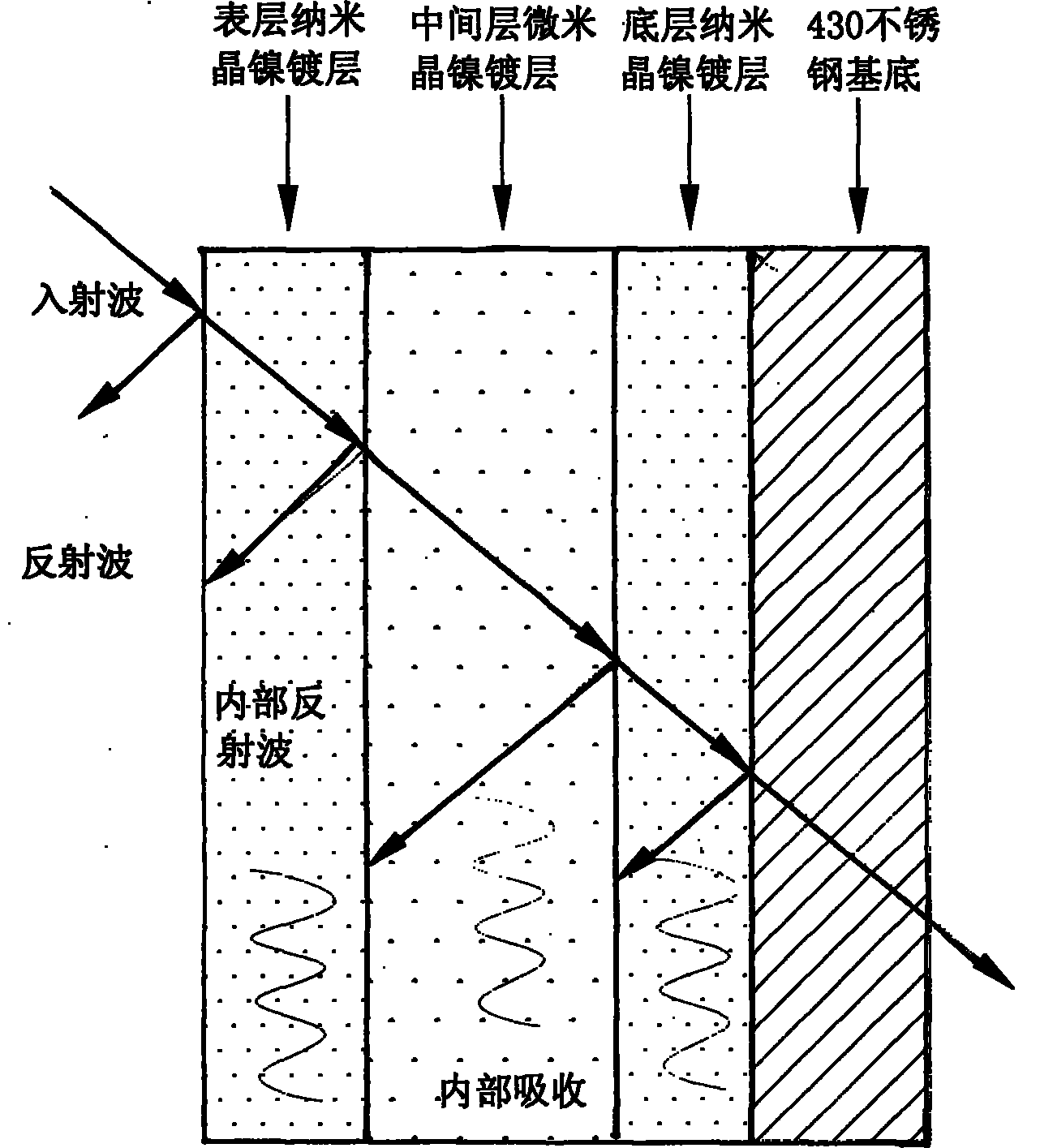

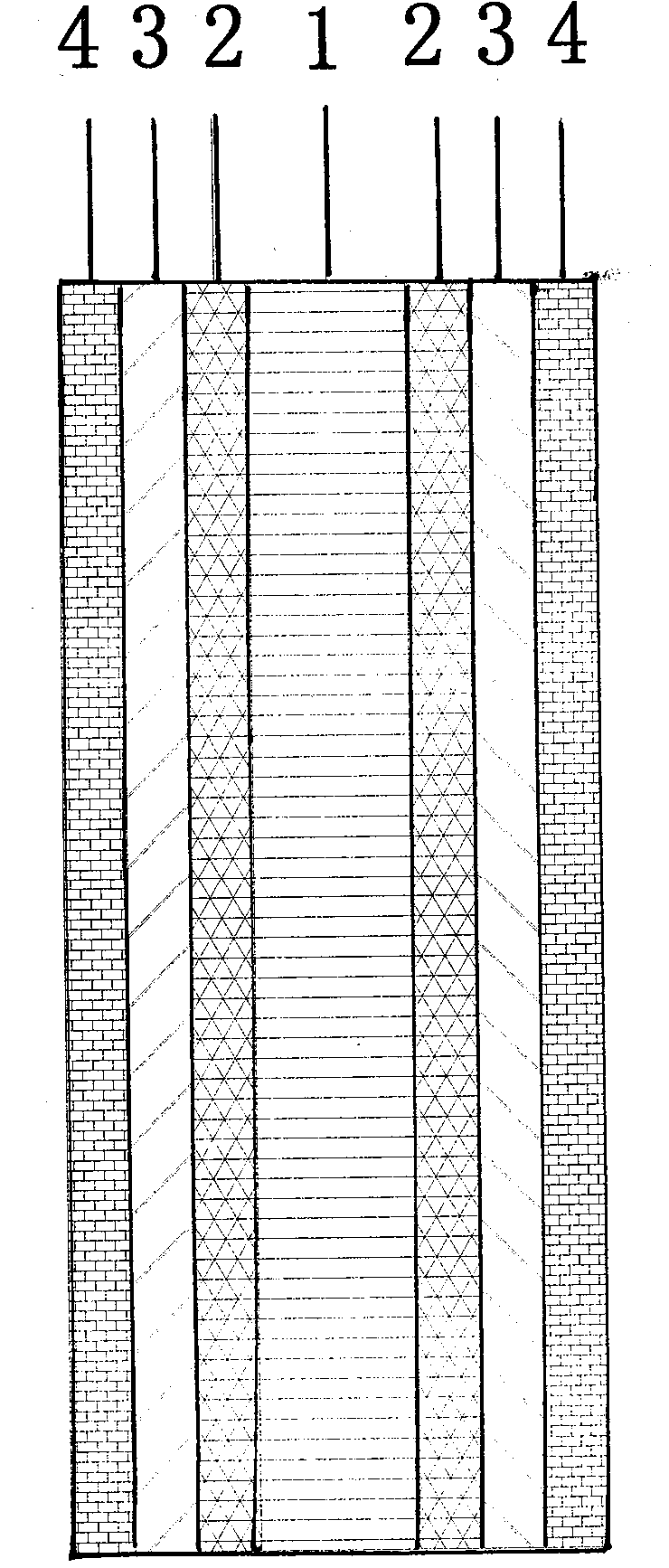

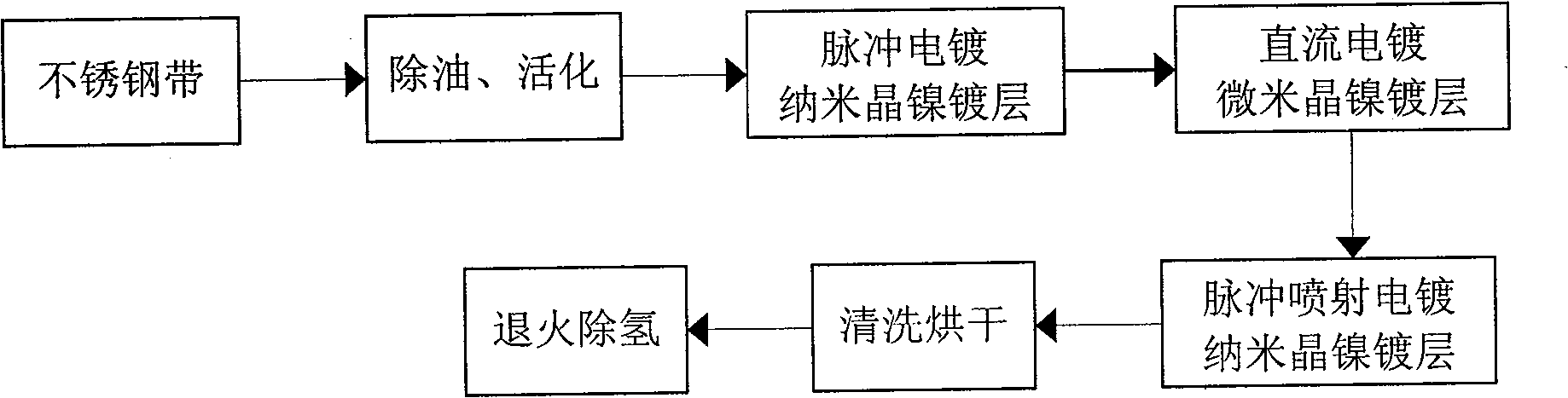

The invention discloses a material for a shell of a connector and a preparation method thereof, is suitable for preparing the shell of the connector and is particularly used for an RJ series network connector. The invention adopts a steel strip as a substrate. Both surfaces of the steel strip are respectively plated with three layers of nickel thin films with different grain sizes. By electroplating a plurality of film structures with different grain sizes on the substrate, the performances of the plating layers are optimized so as to obtain the material for the shell of the connector, which has excellent corrosion resistance, stamping performance and electromagnetic shielding performance. The invention also provides the preparation method of the material, which comprises the following steps: carrying out degreasing and activating on the cold rolling steel strip; firstly using a pulse electroplating method to electroplate a nanocrystalline nickel plating layer; then using a DC electroplating method to electroplate a nanocrystalline nickel plating layer; using a pulse injecting method to electroplate a nanocrystalline nickel plating layer; using distilled water to clean; drying the obtained product; and finally carrying out heat preservation and dehydrogenation on the dried obtained product.

Description

technical field [0001] The invention relates to a connector shell material and a preparation method thereof, belonging to the field of connector materials and preparation, in particular to RJ series network connectors. Background technique: [0002] With the rapid development of information and electronic technology, the application range of connectors has become wider and wider, and has been widely used in computers, telecommunications, communications, industrial electronics, transportation, aerospace transportation, medical equipment, automobile industry and other fields. However, external electromagnetic waves of various frequencies can easily cause poor transmission quality of the connector. In order to solve this problem, the shell of the connector is often set as a metal shell with electromagnetic shielding performance to avoid interference from external electromagnetic waves. Therefore, the shell material of the connector needs to have excellent electromagnetic shiel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01R13/46B32B15/01C25D7/06C25D5/18C25D5/08C25D5/14C25D5/36C25D3/16

Inventor 潘俊安向奎潘勇刘小铷尹业文

Owner HUNAN YONGSHENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com