Method of patterning ultra-small structures

a patterning and ultra-small technology, applied in the field of patterning ultra-small structures, can solve the problems of difficult production of compact, nonporous and smooth vertical surfaces, limited reaction rate,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

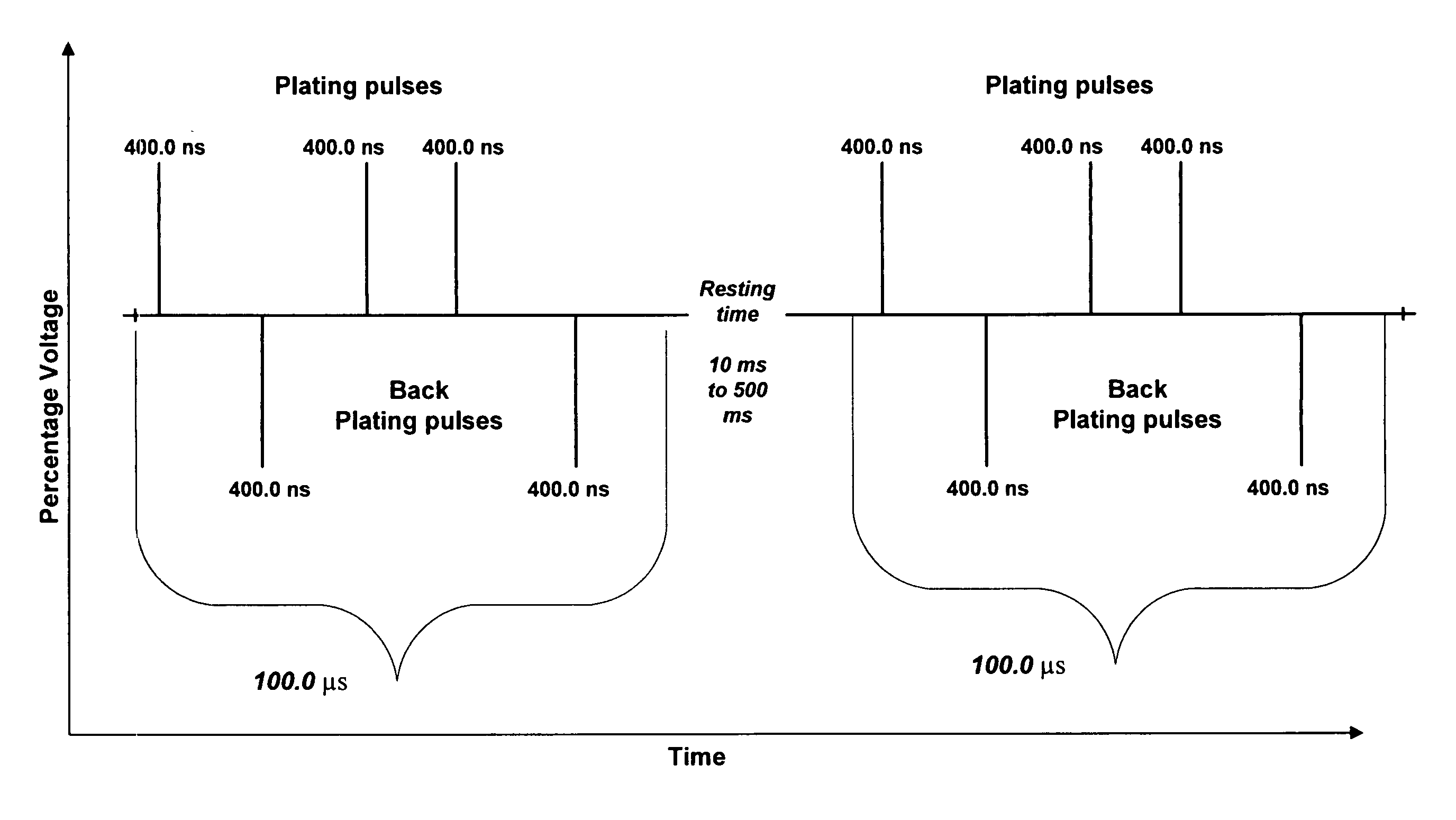

Embodiment Construction

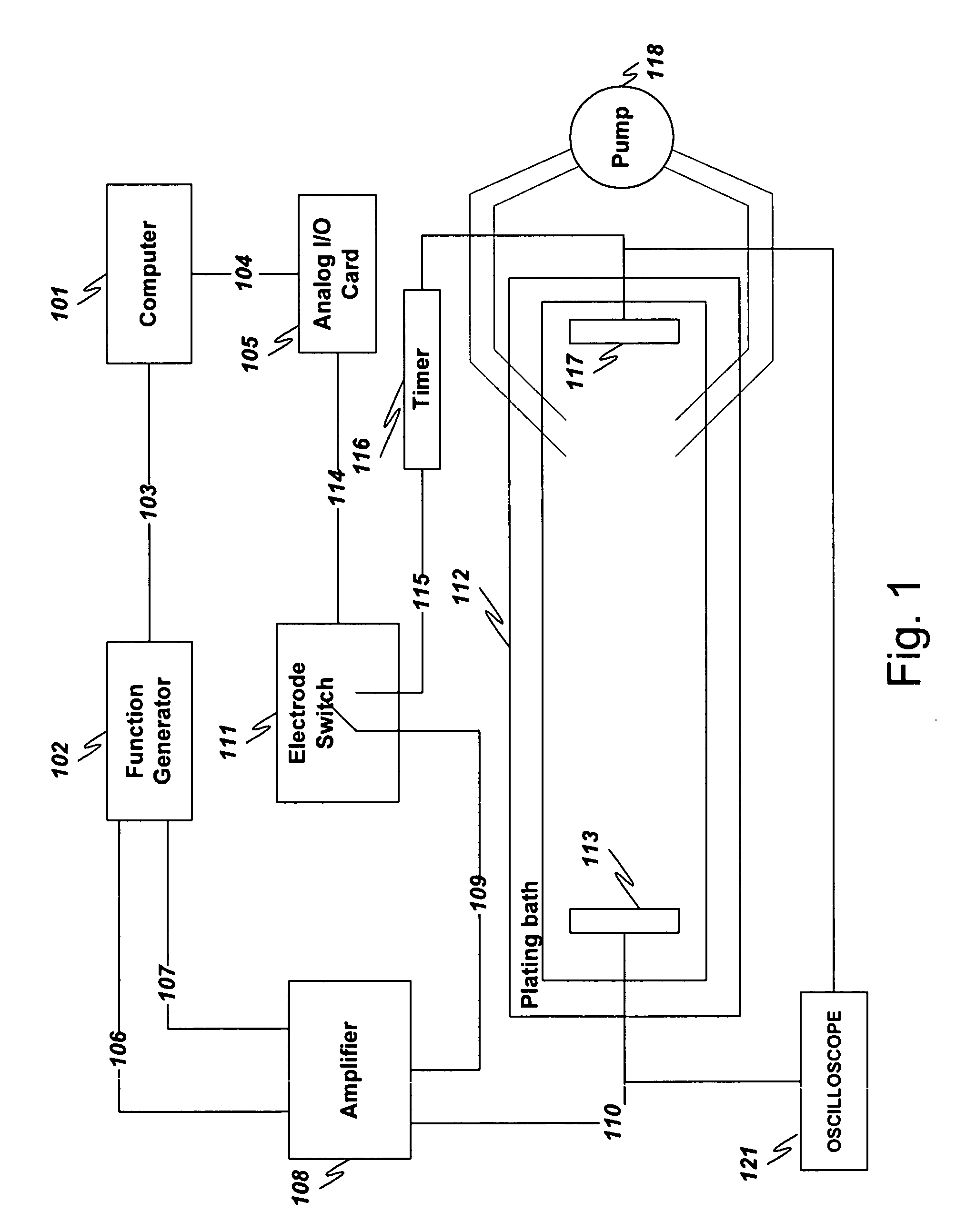

[0025]FIG. 1 is a schematic drawing of a configuration of an example coating apparatus according to embodiments of the present invention. A computer such as personal computer 101 is connected to a function generator 102, e.g., by a standard cable such as USB cable 103. Personal computer 101 is also connected to analog input-output card 105, e.g., by standard USB cable 104.

[0026] Waveform functions on the personal computer 101 are drawn using a standard program included with function generator 102. After the personal computer 101 downloads the waveforms to function generator 102, the function generator sets characteristics such as amplitude, period, and offset of its output electrical signal. The output of function generator 102 is sent to the current amplifier 108 along cables 106 and 107. The cables 106 and 107 may be, e.g., standard USB cables.

[0027] In cases where the output current of the function generator is insufficient to carry out the plating, an amplifier 108 can be intr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| positive voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com