Method of electroplating graphene-metal composite material plating layer by using complex pulses, PCB and motor

A metal composite material, pulse electroplating technology, applied in metal pattern materials, electrolytic coatings, coatings, etc., can solve problems such as limited development, and achieve the effect of simple process, easy regeneration, and ion concentration restoration balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method for utilizing complex pulse electroplating graphene-metal composite coatings. Compared with the prior art, such as water-based electroplating, powder firing and pressing, and chemical vapor deposition, this method is more environmentally friendly. It can be applied to the production of large-area graphene composite material coatings or films, and has low cost, simple process, and does not require high-temperature, high-vacuum and other preparation environments.

[0056] The method specifically includes: using an ionic liquid as an electroplating liquid, wherein graphene oxide is dispersed in the ionic liquid, and metal ions are also contained in the ionic liquid; the graphene-metal composite is obtained by depositing a current control pulse on a cathode substrate. Material coating, the current control pulse includes a forward pulse period in which the current and voltage are negative on the deposition surface, a reverse pulse period in w...

specific Embodiment approach 1

[0059] The ionic liquid system uses choline chloride and ethylene glycol system, and the molar ratio of choline chloride and ethylene glycol is 1:2. The metal ions contained in the ionic liquid are copper ions, and the concentration of the copper ions is 15 mM. The concentration of graphene oxide in the ionic liquid is 0.5g / L.

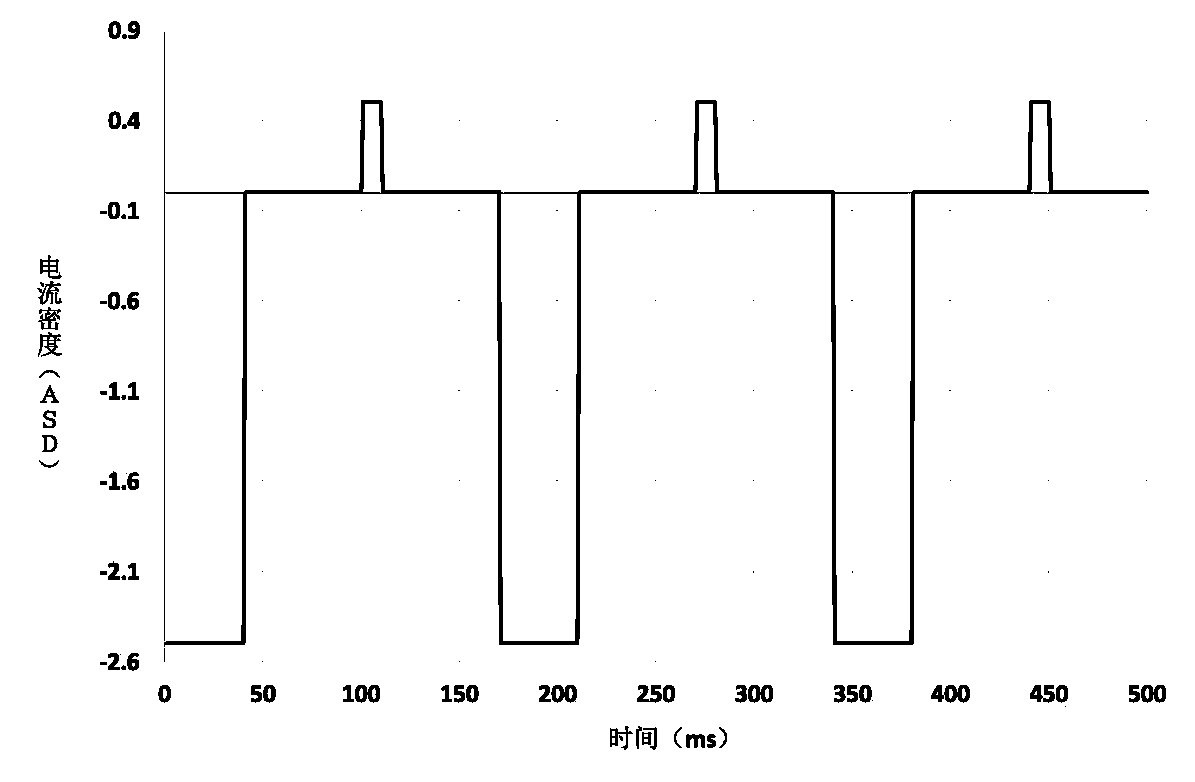

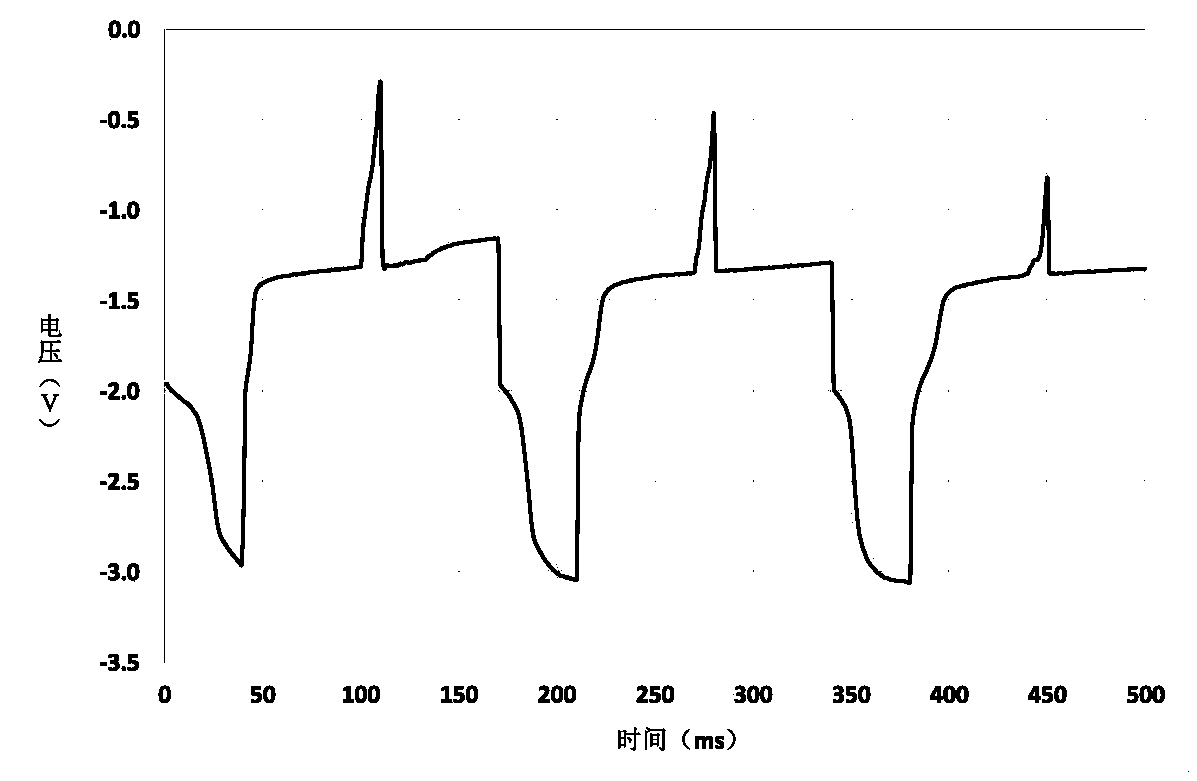

[0060] The graphene-metal composite coating is obtained by depositing on the cathode substrate (copper sheet) with current control pulse. Among them, the working time of the forward pulse period in each complex waveform pulse is 40ms, and the current density is -2.5ASD; the working time of the reverse pulse period is 10ms, and the current density is 0.5ASD; the pause time is 60ms. Pulse current density and corresponding voltage change see figure 1 and figure 2 .

[0061] During complex pulse electroplating, this specific embodiment also uses a stirrer to stir the ionic liquid, so that the concentration of graphene oxide and the concentration of co...

specific Embodiment approach 2

[0064] The ionic liquid system uses choline chloride and ethylene glycol system, and the molar ratio of choline chloride and ethylene glycol is 1:2. The metal ions contained in the ionic liquid are copper ions, and the concentration of the copper ions is 20 mM. The concentration of graphene oxide in the ionic liquid is 0.6g / L.

[0065] The graphene-metal composite material coating was deposited on the cathode substrate (stainless steel sheet) with current control pulse. Among them, the working time of the forward pulse period in each complex waveform pulse is 40ms, and the current density is -3.5ASD; the working time of the reverse pulse period is 15ms, and the current density is 1.0ASD; the pause time is 60ms. Pulse current density and corresponding voltage change see Figure 5 and Image 6 .

[0066] During complex pulse electroplating, this specific embodiment also uses a stirrer to stir the ionic liquid, so that the concentration of graphene oxide and the concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com