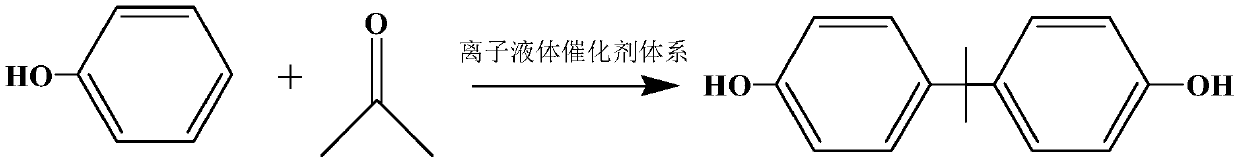

Ionic liquid catalyst system for bisphenol A synthesis and preparation method thereof

An ionic liquid, acidic ionic liquid technology, applied in the preparation of organic compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as poor thermal stability and poor swelling, and achieve quality Good, selective, and speed-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

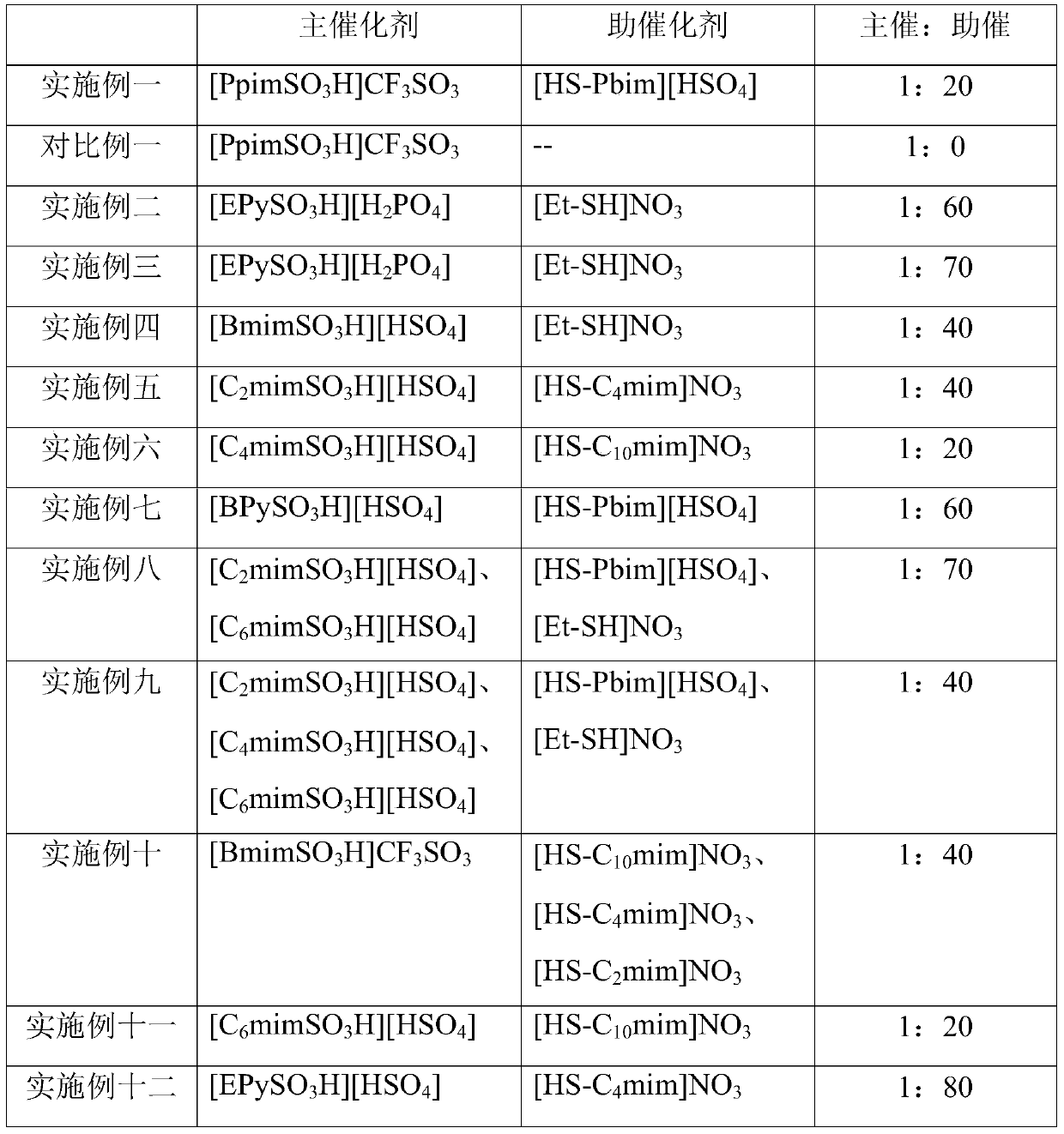

[0027] In addition, for the ionic liquid catalyst system provided by the present invention, the present invention specifically provides a preparation method, comprising the following steps: uniformly mixing the sulfonated acidic ionic liquid and the mercapto-functionalized ionic liquid to obtain the catalyst system.

[0028] In addition, the invention provides an application method of the ionic liquid catalyst system, which is applied in the synthesis process of bisphenol A. Specifically, the invention provides a method for synthesizing bisphenol A, comprising the following steps:

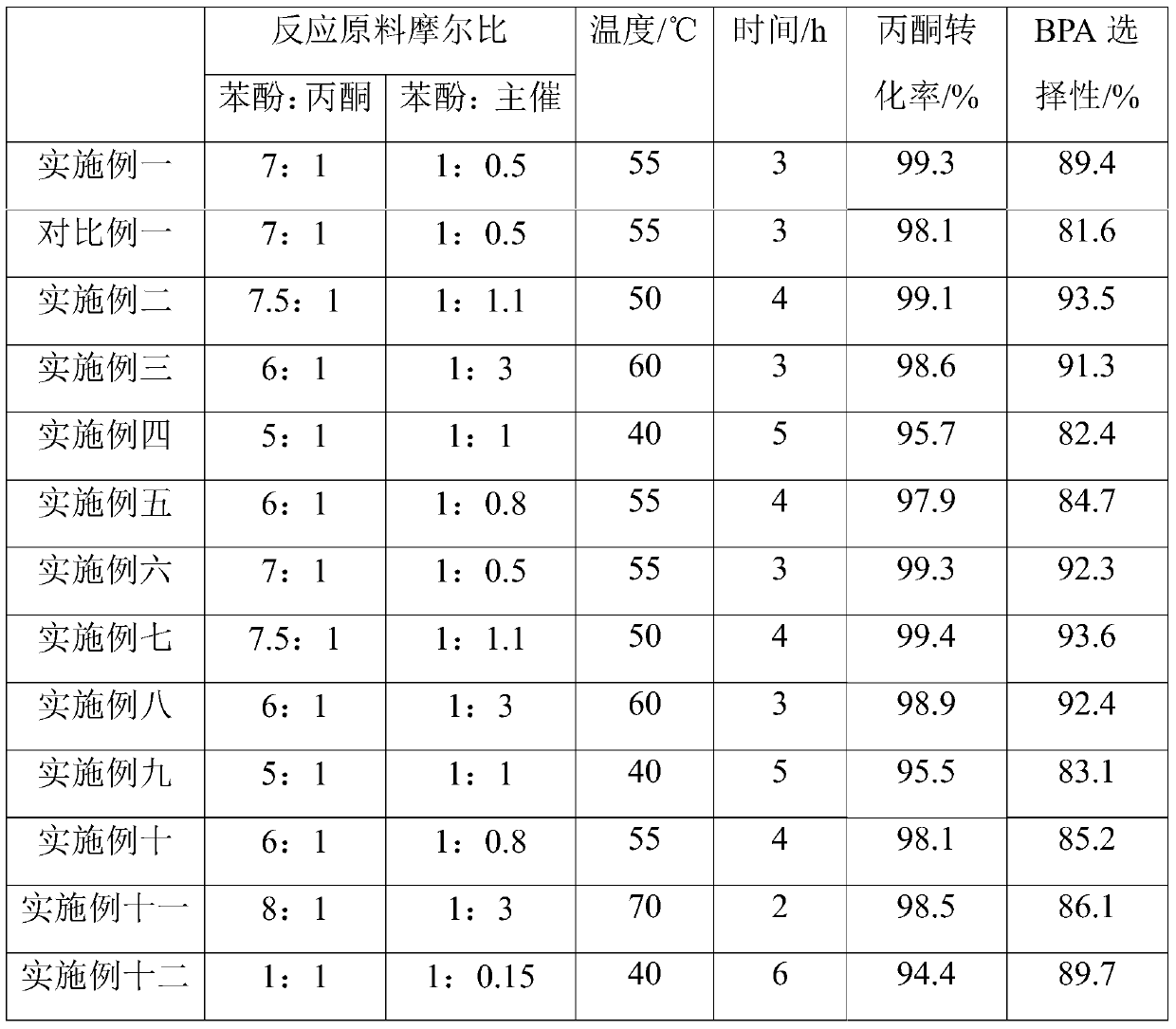

[0029] S101: uniformly mix phenol and acetone according to a preset molar ratio to obtain a reaction mixture; then add the ionic liquid catalyst system in claims 1 to 4, and stir at a preset temperature for a preset time. Among them, in S101, the molar ratio of phenol to acetone is (8-1):1; the molar ratio of phenol to sulfonated acidic ionic liquid in the ionic liquid catalyst system is 1:(0.15-3)...

Embodiment 1

[0034] (1) Preparation of ionic liquid catalyst system

[0035] The sulfonated acidic ionic liquid catalyst is compounded with the sulfhydryl functionalized ionic liquid in a certain ratio to obtain the ionic liquid catalyst system.

[0036] Among them, the sulfhydryl functionalized ionic liquid is [HS-Pbim][HSO 4 ], the sulfonated acidic ionic liquid is [PpimSO 3 H]CF 3 SO 3 ; The molar ratio of sulfhydryl functionalized ionic liquid to sulfonated acidic ionic liquid is 1:20.

[0037] (2) Synthesis of bisphenol A

[0038] S101: Mix phenol and acetone evenly according to a preset molar ratio to obtain a reaction mixture; then add the ionic catalyst system of this embodiment, and stir at a preset temperature for a preset time. Among them, the molar ratio of phenol and acetone is 7:1, phenol and [PpimSO 3 H]CF 3 SO 3 The molar ratio is 1:0.5, the reaction temperature is 55°C, and the reaction time is 3h.

[0039] S102: Separating the product obtained in S102, followed b...

Embodiment 2

[0046] (1) Preparation of ionic liquid catalyst system

[0047] The sulfonated acidic ionic liquid catalyst is compounded with the sulfhydryl functionalized ionic liquid in a certain ratio to obtain the ionic liquid catalyst system.

[0048] Among them, the sulfhydryl functionalized ionic liquid is [Et-SH]NO 3 , the sulfonated acidic ionic liquid is [EPySO 3 H][H 2 PO 4 ]; The molar ratio of sulfhydryl-functionalized ionic liquid to sulfonated acidic ionic liquid was 1:60.

[0049] (2) Synthesis of bisphenol A

[0050] S101: Mix phenol and acetone evenly according to a preset molar ratio to obtain a reaction mixture; then add the ionic catalyst system of this embodiment, and stir at a preset temperature for a preset time. Among them, the molar ratio of phenol to acetone is 7.5:1, phenol and [EPySO 3 H][H 2 PO 4 ] The molar ratio is 1:1.1, the reaction temperature is 50°C, and the reaction time is 4h.

[0051] S102: Separating the product obtained in S102, followed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com