Titanium dioxide nano-cluster@carbon sphere multistage composite structure material as well as preparation method and application thereof

A technology of titanium dioxide and composite structure, applied in the field of photocatalytic materials, can solve cumbersome and complicated problems, achieve the effects of simple and efficient method, reduced electron-hole recombination rate, and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of a titanium dioxide nanocluster@carbon sphere multi-level composite structure material, comprising the following steps: mixing titanocene dichloride, liquid straight-chain carboxylic acid and liquid straight-chain alkane, performing solvothermal reaction, solidifying After liquid separation, titania nanoclusters@carbon spheres multilevel composite structure material was obtained.

[0027] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0028] In the present invention, the liquid linear carboxylic acid preferably includes one or more of formic acid, acetic acid, n-propionic acid, n-butyric acid, n-pentanoic acid, n-hexanoic acid, n-heptanoic acid and n-octanoic acid; Paraffins preferably include n-pentane, n-hexane, n-heptane, n-octane, n-nonane, n-decane, n-undecane, n-dodecane, n-tridecane, n-tetradecane, n-pentadecane One or more of ...

Embodiment 1

[0037] Use 0.15g titanocene dichloride as the titanium source, 5mL n-octanoic acid as the solvent, and 3mL n-heptane as the mixed solvent. After mixing, ultrasonically treat for 10min, stir for 20min, put it into the reactor for solvothermal reaction at 220°C for 24h, and centrifuge Separation, washing with ethanol and water, and drying in an oven at 60°C for 24 hours to finally obtain a titanium dioxide nanocluster@carbon sphere multilevel composite structure material.

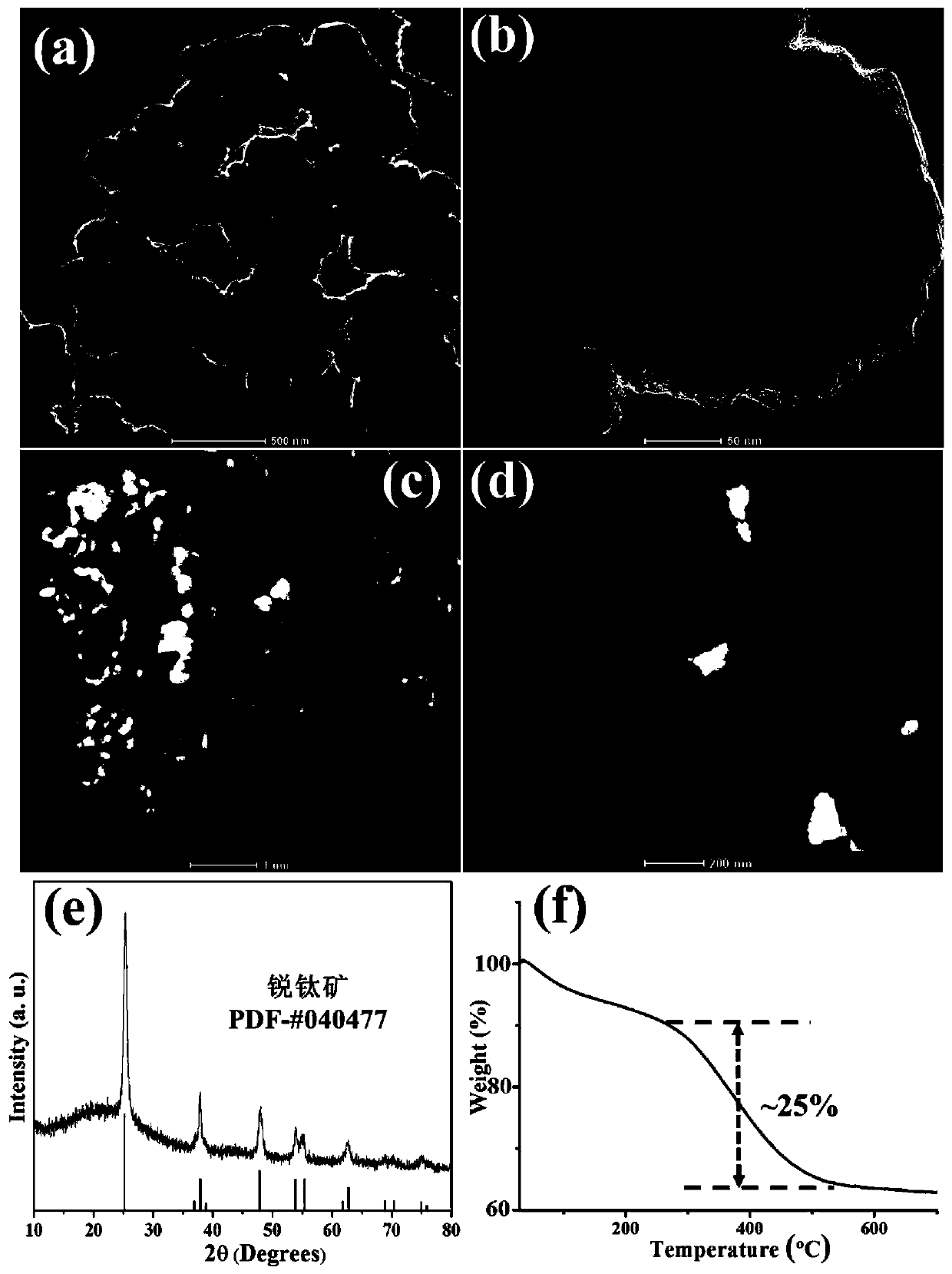

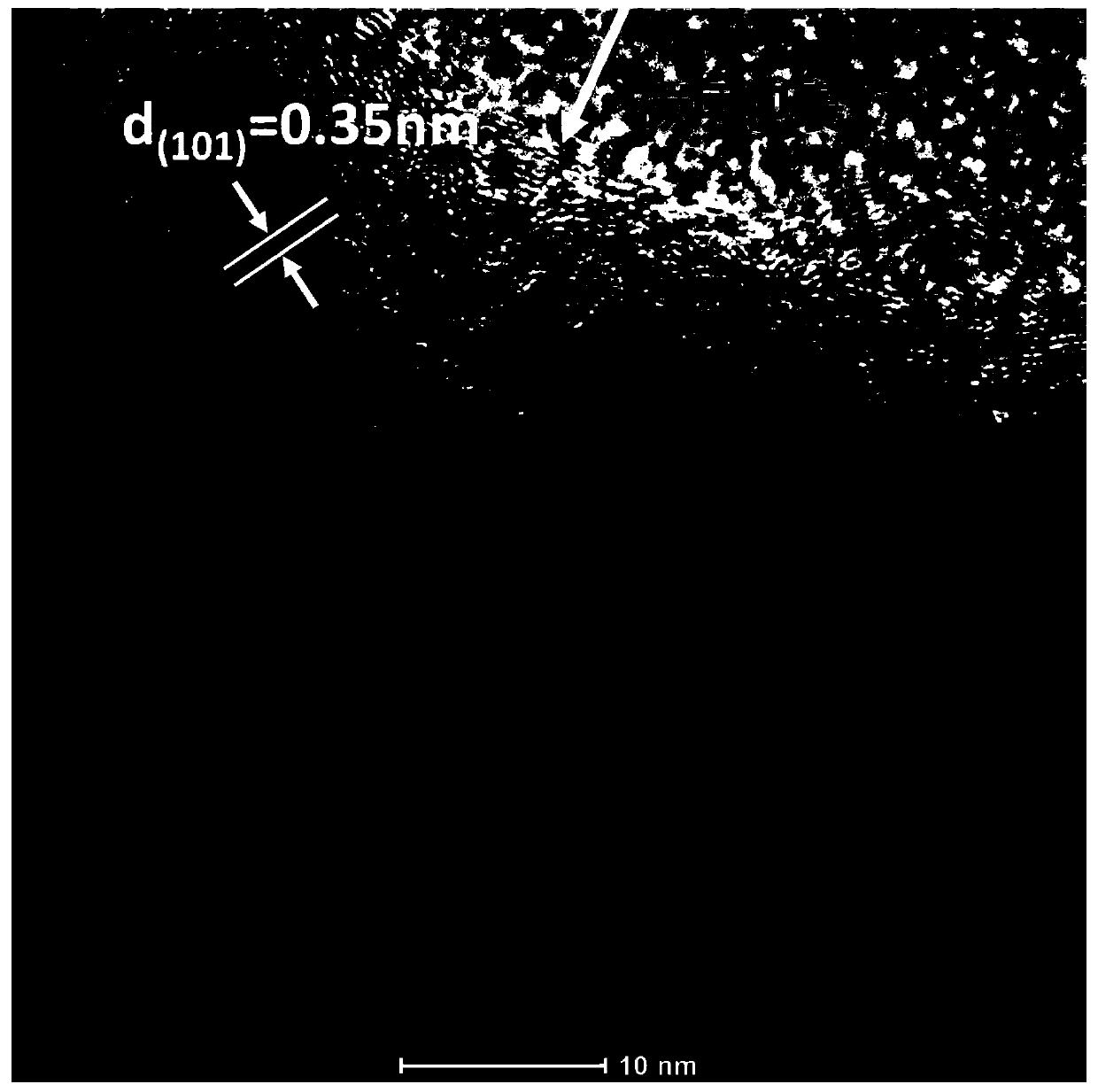

[0038] The material prepared in embodiment 1 is carried out electron microscope observation, the result is as follows figure 1 In (a) ~ (d) shown. Among them, (a) is the transmission electron microscope (TEM) image of the sample, (b) is the partially enlarged TEM image; (c) is the scanning electron microscope transmission mode (STEM) image of the sample, and (d) is the partially enlarged STEM image of the sample .

[0039] Depend on figure 1 From (a) to (d), it can be seen that the sample has a clearly ide...

Embodiment 2

[0044] Use 0.35g titanocene dichloride as the titanium source, 25mL n-hexanoic acid as the solvent, and 12mL n-decane as the mixed solvent. After mixing, ultrasonically treat for 20min, stir for 50min, put it into the reactor for solvothermal reaction at 250°C for 12h, centrifuge Separation, washing with ethanol and water, and drying in an oven at 60°C for 24 hours to finally obtain a titanium dioxide nanocluster@carbon sphere multilevel composite structure material.

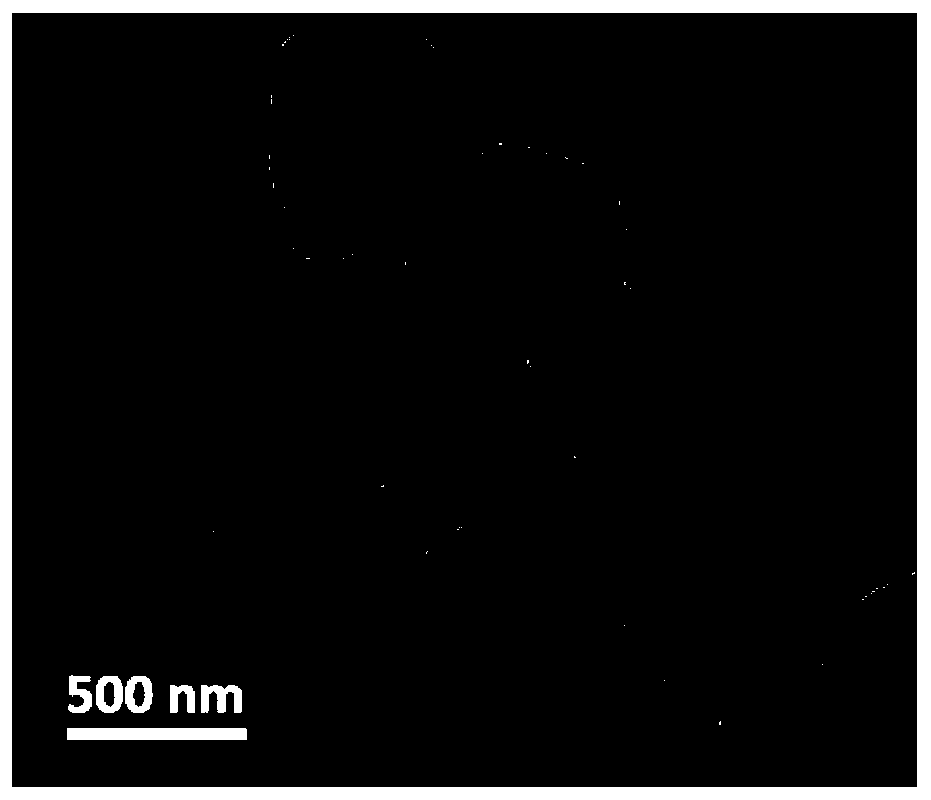

[0045] The material that embodiment 2 makes is carried out transmission electron microscope observation, the result is as follows image 3 shown. image 3 It is shown that the sample has a clearly identifiable hierarchical composite structure with an overall size of about 500 nm. In the figure, the darker discrete distribution along the outer layer is titanium dioxide nanoclusters, and the lighter middle part is carbon spheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com