Method for preparing dichloro dicyclopentadienyl titanium and cis-platinum nano-particles by atomization ultrasound polarity difference technology

A technology of titanocene dichloride and atomization ultrasound, which is applied in the fields of nano-biomedicine and materials, can solve the problems of narrow anti-tumor system, duration of toxic and side effects, etc., and achieves the effects of controllable production, simple equipment, and difficulty in agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

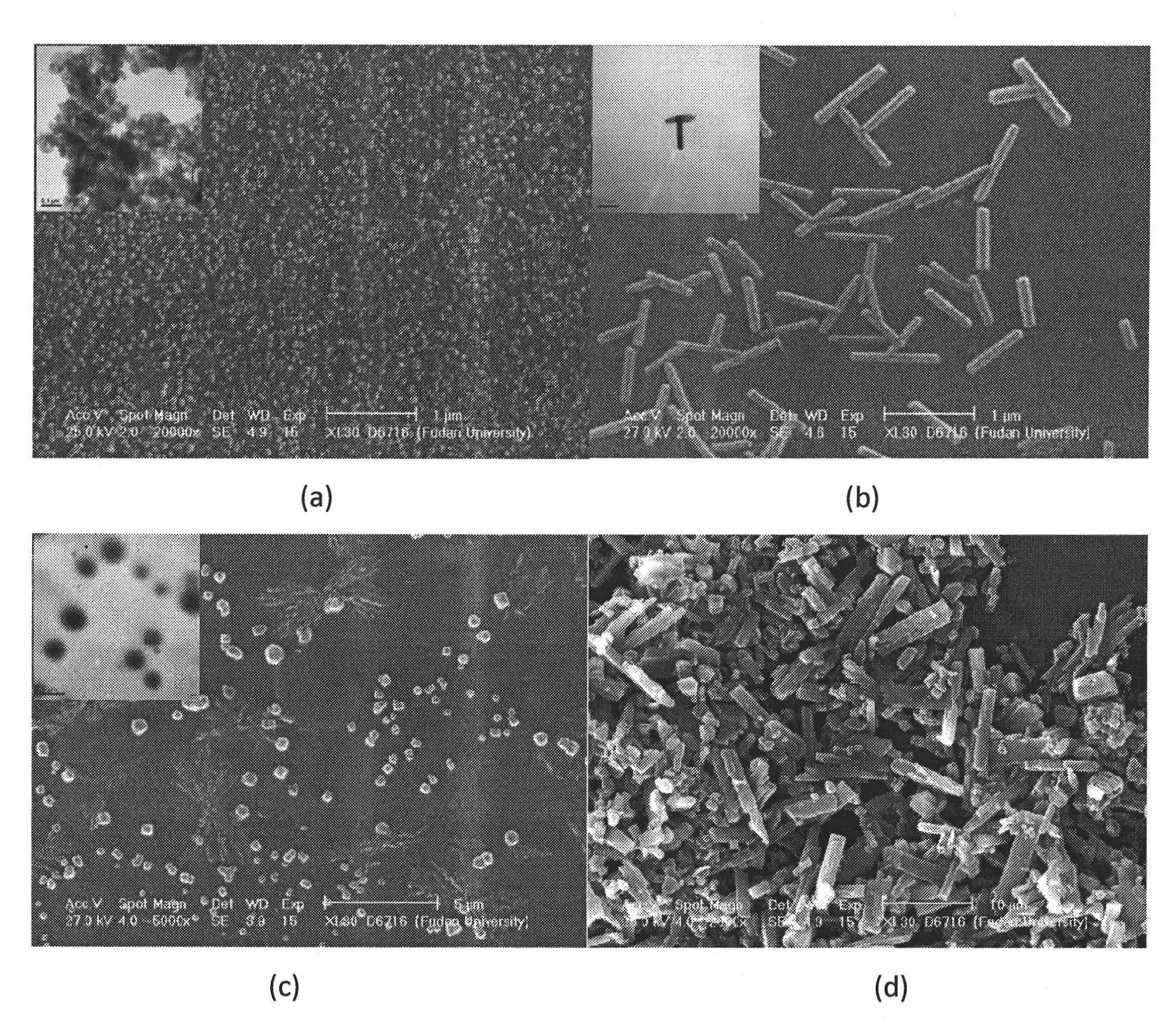

[0043] 1) Accurately measure 0.01 g of titanocene dichloride solute with an analytical balance, mix it with 5 mL of chloroform solvent, put it in a clean glass dish and stir until it is completely dissolved under the action of a magnetic stirrer, and dilute it in a volumetric flask to 25mL to obtain solution A. Measure 20 mL of petroleum ether (60-90° C.) solution as the eluent to obtain solvent B.

[0044] 2) Take 2mL of solution A in a squeeze sprayer, and place solvent B in an ultrasonic environment. Spray solution A into solvent B to precipitate. The ambient temperature is controlled at 15-25°C; the ambient humidity is 45%-50%; the ultrasonic intensity is 100W; the mass flow rate of the spray is 0.4-0.5mL / min. After 5 min, the collected nanoparticles were centrifuged and washed.

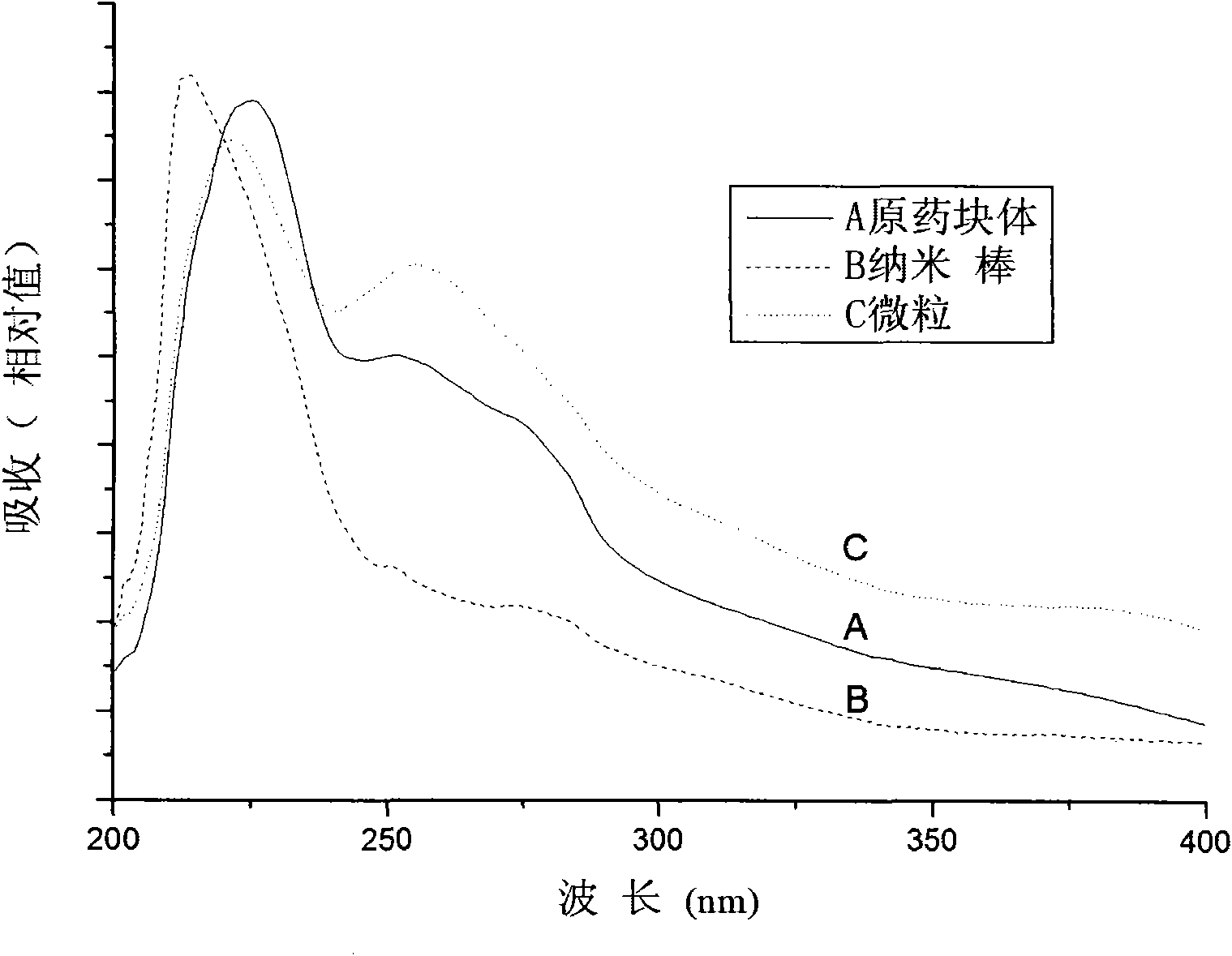

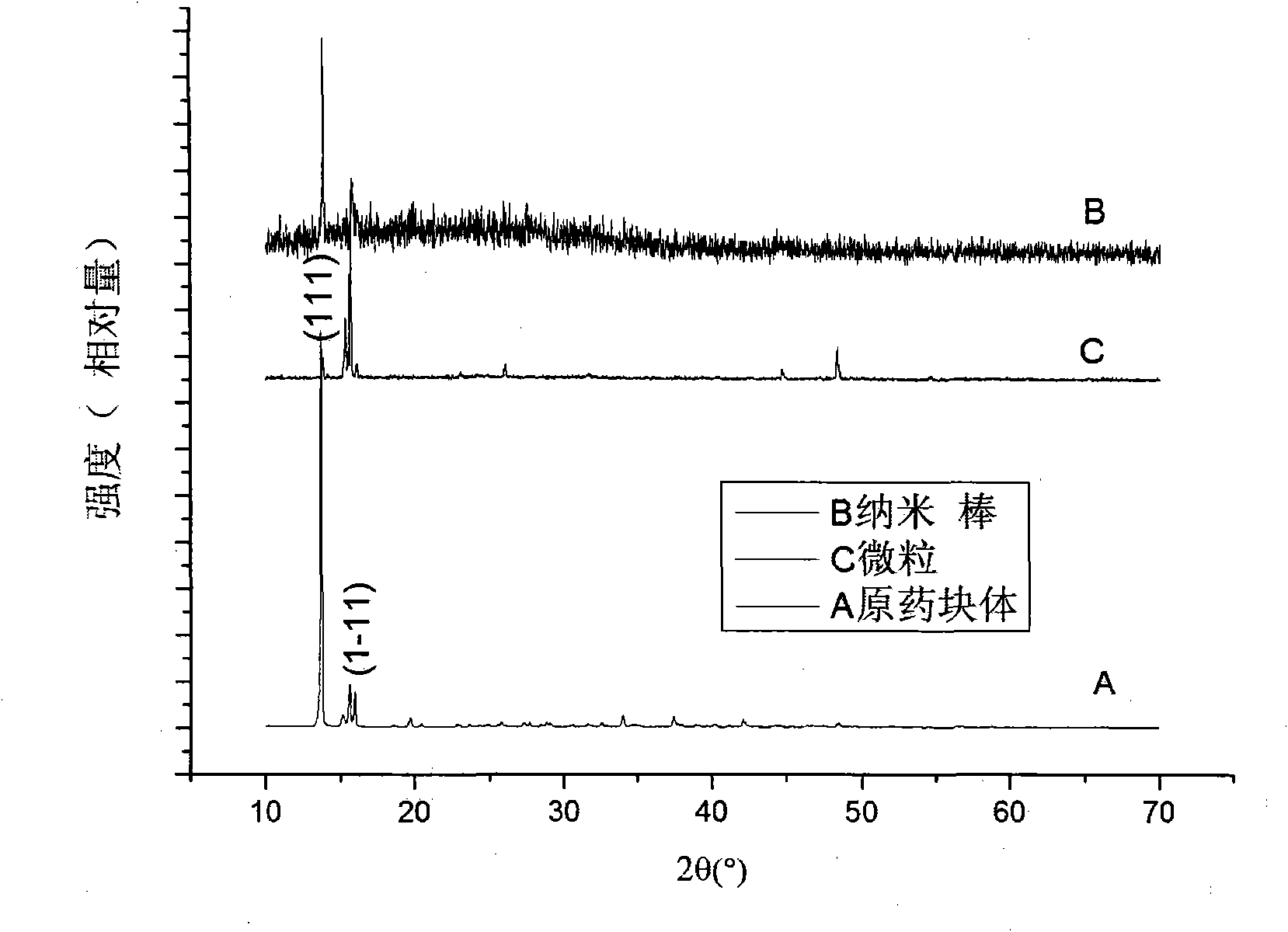

[0045] 3) Characterize the structure and morphology of the obtained product by XRD, SEM, TEM and other means; test the drug release in vitro of the product; and measure its anticancer performa...

Embodiment 2

[0047] 1) Accurately measure 0.01 g of titanocene dichloride solute with an analytical balance, mix it with 5 mL of chloroform solvent, put it in a clean glass dish and stir until it is completely dissolved under the action of a magnetic stirrer, and dilute it in a volumetric flask to 25mL to obtain solution A. Measure 20 mL of petroleum ether (60-90° C.) solution as the eluent to obtain solvent B.

[0048] 2) Take 2mL of solution A in a squeeze sprayer, and place solvent B in an ultrasonic environment. Spray solution A into solvent B to precipitate. The ambient temperature is controlled at 15-25°C; the ambient humidity is 45%-50%; the ultrasonic intensity is 100W; the mass flow rate of the spray is 0.4-0.5mL / min. After 20 min, the collected nanoparticles were centrifuged and washed.

[0049] 3) Characterize the structure and morphology of the obtained product by XRD, SEM, TEM and other means; test the drug release in vitro of the product; and measure its anticancer perform...

Embodiment 3

[0051] 1) Accurately measure 0.1 g of titanocene dichloride solute with an analytical balance, mix it with 5 mL of chloroform solvent, put it in a clean glass dish and stir it under the action of a magnetic stirrer until it is completely dissolved, and dilute it in a volumetric flask to 25mL to obtain solution A. Measure 20 mL of petroleum ether (60-90° C.) solution as the eluent to obtain solvent B.

[0052] 2) Take 2mL of solution A in a squeeze sprayer, and place solvent B in an ultrasonic environment. Spray solution A into solvent B to precipitate. The ambient temperature is controlled at 15-25°C; the ambient humidity is 45%-50%; the ultrasonic intensity is 100W; the mass flow rate of the spray is 0.4-0.5mL / min. After 5 min, the collected nanoparticles were centrifuged and washed.

[0053] 3) Characterize the structure and morphology of the obtained product by XRD, SEM, TEM and other means; test the drug release in vitro of the product; and measure its anticancer perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com