Heterogeneous catalyst for synthesizing diphenyl carbonate, and preparation method thereof

A technology of diphenyl carbonate and heterogeneous catalyst, applied in the fields of catalytic chemistry and organic chemistry, can solve problems such as difficult separation and difficult recycling, and achieve the effect of promoting the reaction, not easy to break or fall off, and ensuring catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 2.84g (0.01mol) of tetraisopropyl titanate in anhydrous methanol, stir and mix evenly, add 6.63g of MCM-41 molecular sieve (mass ratio 30:70), filter after hydrothermal synthesis reaction at 105°C for 24h, and Air-dry the filtered mixture for 2 hours, then dry in an oven for 8 hours at a drying temperature of 80°C to obtain a catalyst intermediate; then dissolve the catalyst intermediate in anhydrous methanol, stir for about 2 hours, and slowly add chlorine dropwise in an ice-water bath 0.005 mol of sulfonic acid, then stirred at room temperature for 2 days, filtered and washed until neutral, and the obtained solid was dried in an oven at 60°C for 20 hours to obtain Catalyst 1.

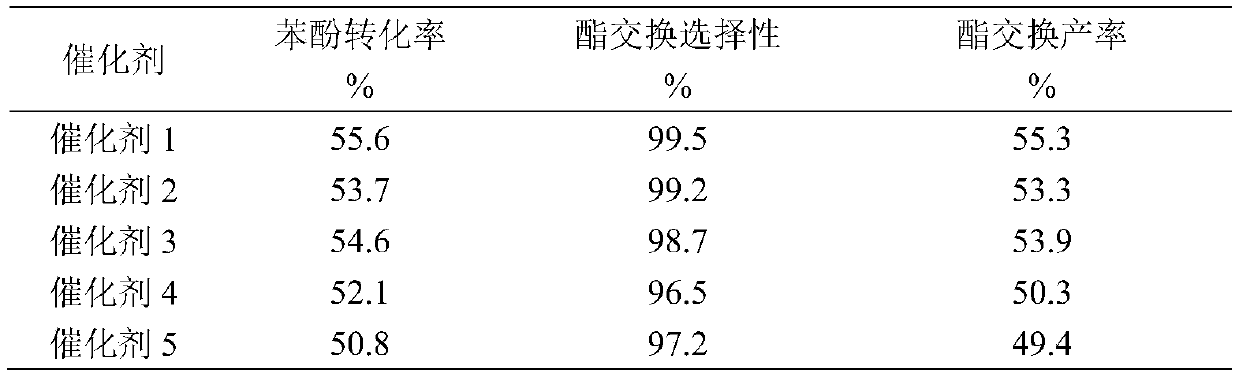

[0026] Phenol and dimethyl carbonate are transesterified under the above catalyst. In a four-necked flask equipped with a gas guide tube, a thermometer and a rectifying column, the molar ratio of dimethyl carbonate to phenol is 1:1, and the catalyst dosage is 1wt. %, the reaction time ...

Embodiment 2

[0028] Dissolve 2.48g (0.01mol) titanocene dichloride in anhydrous methanol, stir and mix evenly, add 5.79g MCM-41 molecular sieve (mass ratio 30:70), filter after hydrothermal synthesis at 105°C for 24h, and The mixture obtained by filtration was air-dried for 2 hours, then dried in an oven for 8 hours at a drying temperature of 80°C to obtain a catalyst intermediate; then dissolved the catalyst intermediate in anhydrous methanol, stirred for about 2 hours, and slowly added chlorosulfur in an ice-water bath Acid 0.005mol, then stirred at room temperature for 2 days, filtered and washed until neutral, and the obtained solid was dried in an oven at 60°C for 20 hours to obtain Catalyst 2.

[0029] Phenol and dimethyl carbonate are transesterified under the above catalyst. In a four-necked flask equipped with a gas guide tube, a thermometer and a rectifying column, the molar ratio of dimethyl carbonate to phenol is 1:1, and the catalyst dosage is 1wt. %, the reaction time is 10h,...

Embodiment 3

[0031] Dissolve 2.80g (0.01mol) of dicyclopentadienyl dimethyltitanium in anhydrous methanol, stir and mix evenly, add 6.53g of MCM-41 molecular sieve (mass ratio 30:70), after 24 hours of hydrothermal synthesis reaction at 105°C Filter, and air-dry the filtered mixture for 2 hours, then dry in an oven for 8 hours at a drying temperature of 80°C to obtain a catalyst intermediate; then dissolve the catalyst intermediate in anhydrous methanol, stir for about 2 hours, and slowly Add 0.005 mol of chlorosulfonic acid dropwise, then stir at room temperature for 2 days, filter and wash until neutral, and dry the obtained solid in an oven at 60°C for 20 hours to obtain catalyst 3.

[0032] Phenol and dimethyl carbonate are transesterified under the above catalyst. In a four-necked flask equipped with a gas guide tube, a thermometer and a rectifying column, the molar ratio of dimethyl carbonate to phenol is 1:1, and the catalyst dosage is 1wt. %, the reaction time is 10h, and the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com