Rapid UV (Ultraviolet) photo-cured ink and application method thereof

A technology of ink and composite light, which is applied in the direction of ink, applications, household appliances, etc., can solve the problems of UV direct writing technology efficiency bottleneck, etc., and achieve the effect of improving photocuring efficiency, photosensitivity, and fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of composite photoinitiator

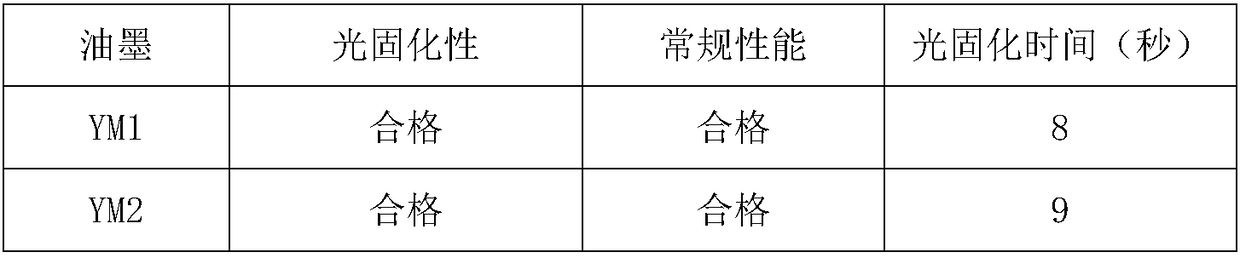

[0034] Different types of photoinitiators are selected and matched in weight to configure different composite photoinitiators. The photoinitiators and their weight ratios used in different composite photoinitiators are shown in Table 1 below. The weight of each photoinitiator in Table 1 is the number of grams, and each composite photoinitiator is configured with 100 grams for the preparation of photocurable ink.

[0035] Table 1: Composite photoinitiator formula table

[0036]

Embodiment 2

[0037] Embodiment 2: the preparation of DI special printing ink

[0038] Take 35g of unsaturated acrylic resin and 30g of acrylic epoxy resin, then take 9g of composite photoinitiator, 9g of crosslinking agent triallyl isocyanurate, 1.5g of defoamer KS-66, 6g of solvent PMA, 1.5 G adhesion promoter PM-2 and 8g talcum powder, mixed evenly and ground to prepare DI special ink.

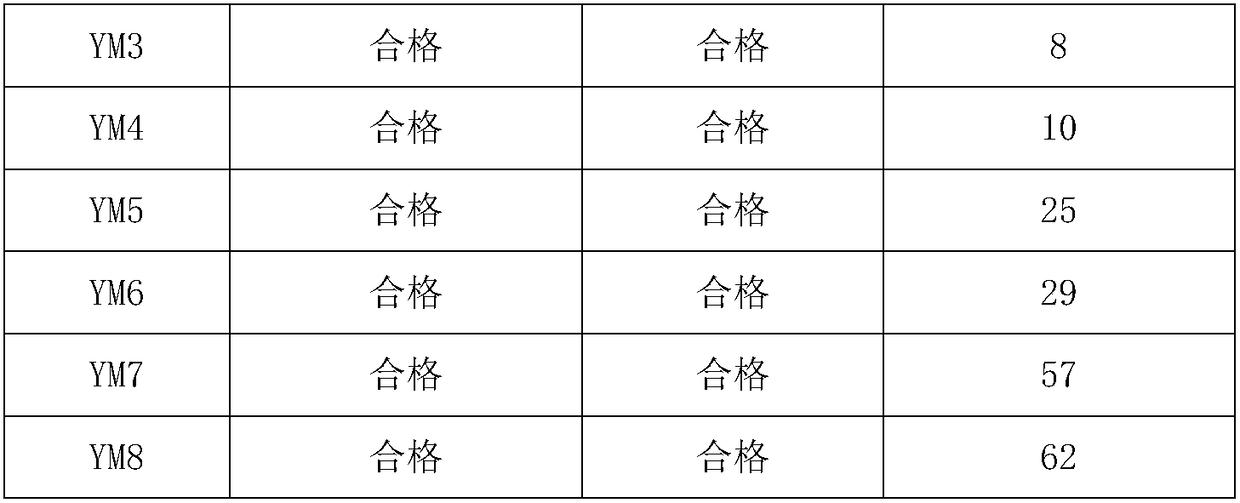

[0039] The composite photoinitiators in Table 1 were used to prepare DI special ink according to the above method, and then the UV curing experiment was carried out to study the UV curing time and curing effect respectively.

[0040] Prepare inks YM1, YM2, YM3, YM4, YM5, YM6, YM7 and YM8 with the composite photoinitiators in Table 1 respectively, the composite photoinitiator used in ink YM1 is FG1, and so on, the composite photoinitiator used in ink YM8 The agent is FG8.

Embodiment 3

[0041] Embodiment 3: the measurement of ink photocuring time

[0042]The method of determining the curing time is to apply the ink on the circuit board, and then use a mixed ultraviolet light (LDI exposure machine) to draw the circuit diagram, adjust the moving speed of the ultraviolet light, and determine the time the ultraviolet light stays in the ink layer. Check whether the layer meets the requirements of photocurability, hardness, adhesion, solder heat resistance, solvent resistance, acid resistance, and alkali resistance. If the requirements are met, it is clear that the ink can be used for direct photocuring, and it can be used After direct photocuring, count the time spent in photocuring. The specific results are shown in Table 2 below.

[0043] Table 2 Photocuring performance and photocuring time of photocurable ink

[0044]

[0045]

[0046] Replacement in Example 1, the ketoxime ester photoinitiator is changed to OXE-2, the thioxanthone photoinitiator is cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com