Titanium/zirconium-doped cerium-based metal organic framework material for degrading paraoxon methyl

A methyl paraoxon, organic framework technology, applied in the direction of organic compound/hydride/coordination complex catalyst, water/sewage treatment, chemical/physical process, etc., can solve the risk of excessive pesticide residues, pesticide use increase and other problems, to achieve the effects of low price, high degradation efficiency, and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

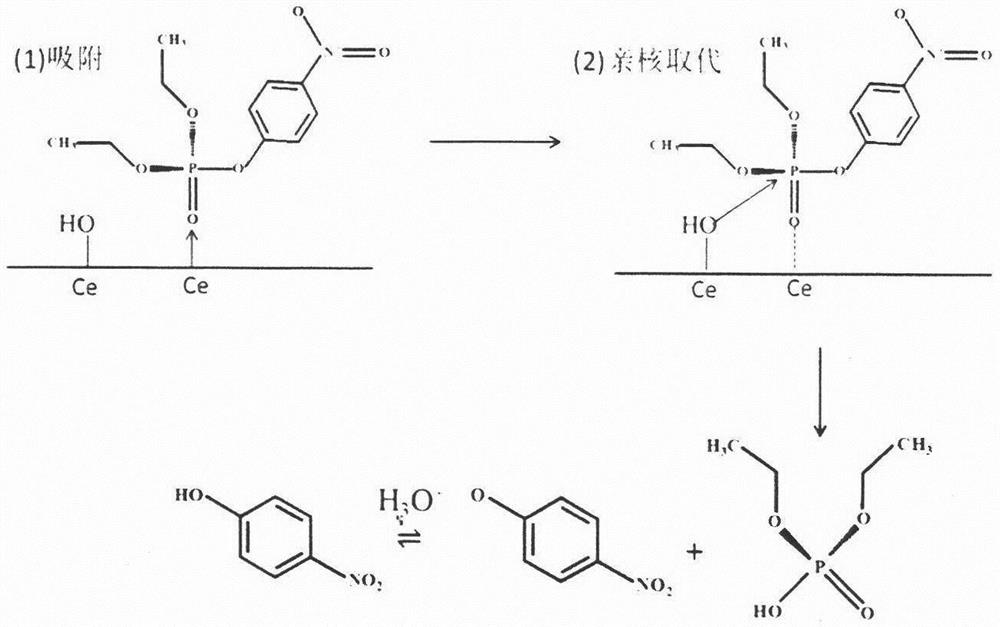

Method used

Image

Examples

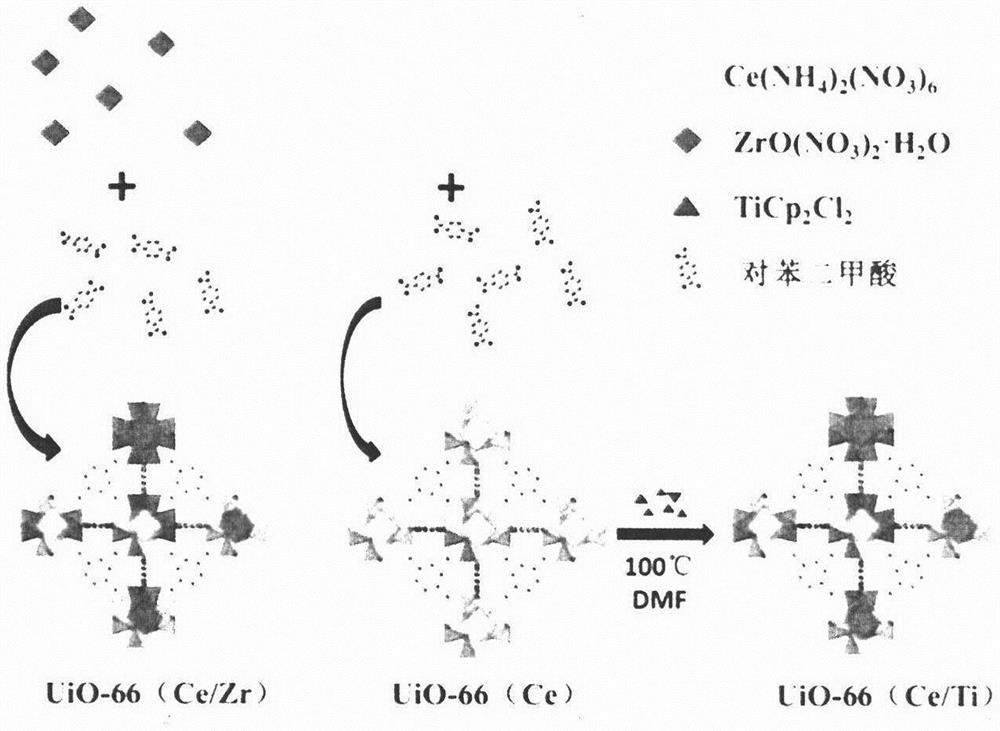

Embodiment 1

[0033] Weigh 7.018g of cerium nitrate, dissolve into 24mL of ultrapure water, and give 0.5333mol / L of aqueous cerium nitrate solution. Weigh 2.124 g of terephthalic acid to a round bottom flask containing 75 mL of N, N-dimethylformamide. Under the condition of continuous magnetic stirring, an aqueous solution of cerium ammonium nitrate was added. The flask is sealed, magnetically stirred for 30 min at room temperature to make it mix evenly, and then heated for 30 min under the condition of continuous magnetic stirring at 100 °C. The obtained solution is cooled to room temperature, centrifuged for collection to obtain a pale yellow pellet. Centrifuged washes (6000 r / min) 3 times with N, N-dimethylformamide and alcohol, respectively. The resulting UiO-66(Ce) precipitate was separated from ethanol and then dried in vacuum overnight in an electrothermal vacuum drying chamber at 80 °C.

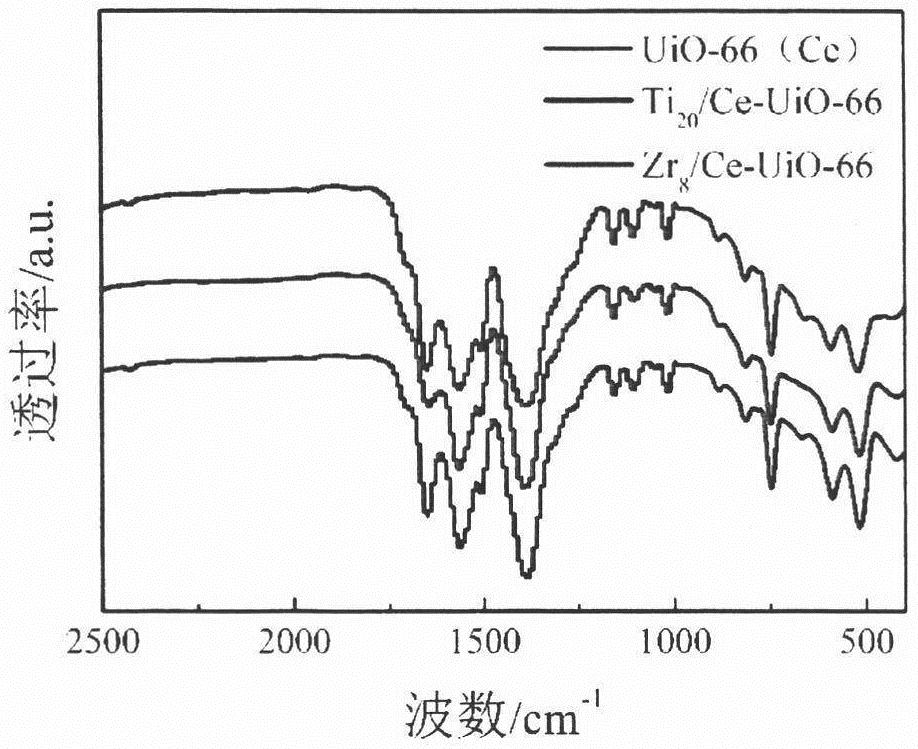

Embodiment 2

[0035] The ratio of Ce / Ti is controlled by changing the molar ratio of the raw material. Weigh a certain mass of titanium dichlorodiclodiene (TiCp 2 Cl 2 with UiO-66 (Ce). Under the condition of continuous magnetic agitation, the weighed drug is added to a round-bottom flask containing 125mL of N, N-dimethylformamide. Magnetically stirred at room temperature for 30min to obtain a homogeneous solution, and then under the condition of continuous magnetic stirring at 100 ° C, heating for 5h. The resulting solution is cooled to room temperature and centrifuged to collect (6000 r / min) of the pellet. Wash 3 times with N, N-dimethylformamide and alcohol, respectively. The resulting Ti is isolated from ethanol x / Ce-UiO-66 precipitated in an electrothermal vacuum drying chamber at 80 °C for vacuum drying overnight. Ti in different proportions x The synthesis method of / Ce-UiO-66 is the same except for the amount of raw materials added, and the temperature and time of synthesis are the sam...

Embodiment 3

[0037]Weigh 11.6880g of cerium nitrate, dissolve into 40mL of ultrapure water, and prepare into an aqueous solution of 0.533mol / L of cerium nitrate (A liquid). Weigh 2.4649g of zirconium nitrate, dissolve into 20mL of ultrapure water, and prepare 0.533mol / L of zirconium nitrate aqueous solution (B solution). Weigh 1.276g of terephthalic acid, dissolve in a 250mL flask containing 36mL of N, N-dimethylformamide under the condition of continuous magnetic stirring, and then add 10.3mL of formic acid dropwise in the mixture. Different proportions of Zr are synthesized by controlling the volume ratio of liquid A and B x / Ce-UiO-66。 Seal the flask, magnetically stir at room temperature for 30min, and then heat for 30min under the condition of continuous magnetic stirring at 100 °C. The resulting solution is cooled to room temperature and centrifuged to collect (6000 r / min) of the pellet. The resulting pellet was washed twice by centrifugation with N, N-dimethylformamide and 4 times by ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com