Low-odor and high-wear-resistant PET composition and preparation method thereof

A low-odor, composition technology, applied in the polymer field, can solve the problems of poor corona resistance, limited application of polyethylene terephthalate, etc., achieve excellent mechanical properties, avoid serious performance degradation, and melt and mix smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

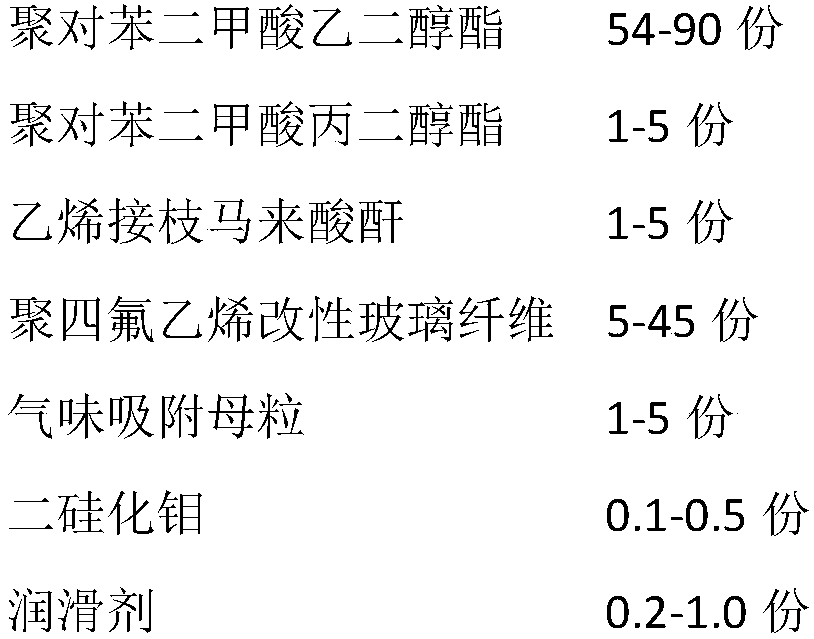

Method used

Image

Examples

preparation example Construction

[0031] Preparation of odor adsorption masterbatch: 100 parts of high-density polyethylene, 5 parts of hydrophobic diatomaceous earth, 10 parts of hydrophobic activated carbon, 5 parts of needle-shaped zeolite molecular sieve, 10 parts of zinc ricinoleate, 5 parts of nano-silica, hard 1 part of calcium fatty acid and 5 parts of melamine were mixed evenly, and then extruded and granulated in a twin-screw extruder to obtain odor-absorbing masterbatches.

[0032] The number-average molecular weight of polytetrafluoroethylene is 3 million, and the elongation at break is 3%-10%.

[0033] The crystallinity of high-density polyethylene is 85%, and the number average molecular weight is 250,000.

[0034] The melt index of polyethylene terephthalate is 25-28g / 10min; the melt index of polypropylene terephthalate is 28-30g / 10min.

Embodiment 1

[0036] 70 parts of polyethylene terephthalate, 1 part of polytrimethylene terephthalate, 1 part of ethylene grafted maleic anhydride, 3 parts of odor absorption masterbatch, 0.5 part of molybdenum disilicide, 1 part of silicone powder , 0.5 parts of antioxidant 1098, and 0.5 parts of antioxidant 168 are poured into a high-speed mixer, stirred at a high speed, mixed until uniform, and then added to a twin-screw extruder, and 30 parts of polytetrafluoroethylene modified glass fibers are fed from the glass fiber port Adding, melting and extruding and then granulating to prepare a polyethylene terephthalate composition with low odor, low emission and high wear resistance.

[0037] The temperature of the first zone of the twin-screw extruder is 180°C, the temperature of the second zone is 180°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 210°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zone is 245°C; Twin-scr...

Embodiment 2

[0039] 54 parts of polyethylene terephthalate, 2 parts of polytrimethylene terephthalate, 2 parts of ethylene grafted maleic anhydride, 1 part of odor absorption masterbatch, 0.2 part of molybdenum disilicide, 0.2 part of silicone powder , 0.1 part of antioxidant 1098, and 0.1 part of antioxidant 168 are poured into a high-speed mixer, stirred at a high speed, mixed until uniform, and then added to a twin-screw extruder, and 30 parts of polytetrafluoroethylene modified glass fibers are fed from the glass fiber port Adding, melting and extruding and then granulating to prepare a polyethylene terephthalate composition with low odor, low emission and high wear resistance.

[0040] The temperature of the first zone of the twin-screw extruder is 190°C, the temperature of the second zone is 190°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 300°C, and the temperature of the sixth zone is 300°C; Twin-sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com