Low odor and emission nylon 6 composition and preparation method thereof

A low-emission, low-odor technology, which is applied in the field of low-odor, low-emission nylon 6 composition and its preparation, can solve problems such as little practical value, processing problems, and deterioration of alloy physical properties, so as to achieve low molding performance. Effect of affected, low emission, low odor properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment, the present invention is described in further detail: the raw material used of embodiment is as follows:

[0040] (1) Nylon 6 resin, relative viscosity 2.8, China Yueyang Baling Petrochemical Chemical Fiber Co., Ltd.;

[0041] (2) Talc powder, 12 microns in diameter, China Liaoning Haicheng Jingjing Minerals Co., Ltd.;

[0042] (3) Calcium carbonate, 20 microns in diameter, Shanghai Excellence Nano New Material Co., Ltd.;

[0043] (4) Polypropylene grafted with maleic anhydride, melt index: 30g / 10min (230°C, 2.16KG), Shanghai Senze Company;

[0044] (5) Attapulgite, with a purity of 80%, a particle size of 300 mesh, and an exchangeable calcium ion content of 12mmol / 100g, Jiangsu Xuyi Attapulgite Clay Company;

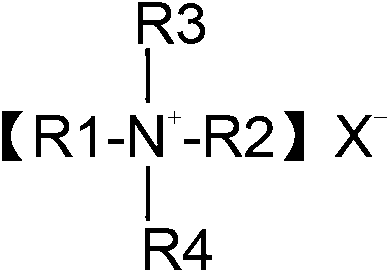

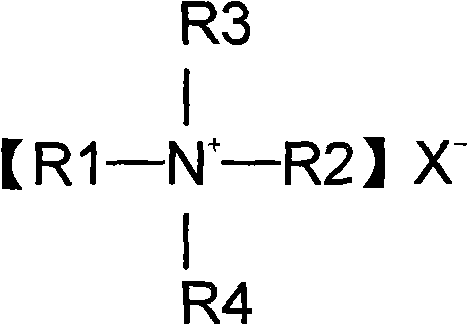

[0045] (6) quaternary ammonium salt type surfactant, chemically pure cetyltrimethylammonium bromide, provided by Shanghai Chemical Reagent Co., Ltd.;

[0046] (7) ultra-high molecular weight polysiloxane, its molecular wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com