Novel low-odor and low-emission ABS resin compound and preparation method thereof

An ABS resin and low-odor technology, which is applied in the field of new low-odor, low-emission ABS resin compound and its preparation, can solve the problems of complex follow-up treatment process and inconvenient use by customers, so as to achieve unaffected physical and mechanical properties, Molding processing is not affected, the effect of low odor characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

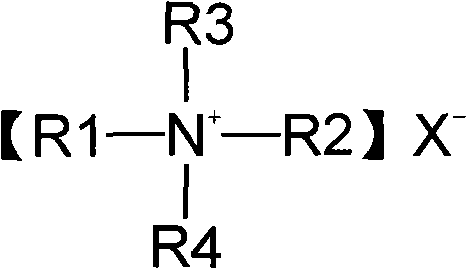

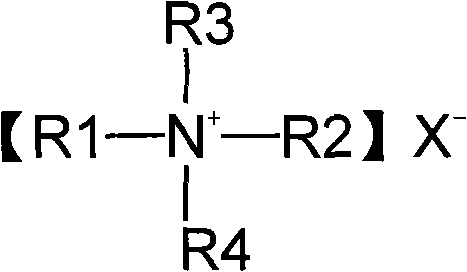

Method used

Image

Examples

Embodiment 1

[0045] Preparation of hydrophobic odor-absorbing masterbatch: Weigh 60% of ABS and 40% of hydrophobic odor-absorbing agent, dry mix them in a high-speed mixer for 3-5 minutes, then melt-extrude them in a twin-screw extruder, and granulate. Aluminum foil is vacuum sealed and ready for use. The extrusion process is as follows: zone 1 200-210°C, zone 2 210-220°C, zone 3 210-220°C, zone 4 205-215°C; the residence time of the entire extrusion process is 1 -2 minutes, the pressure is 12-18MPa.

[0046] Preparation of low-odor ABS resin compound: dry-mix 100 parts of ABS, 1 part of hydrophobic odor-absorbing masterbatch, 0.2 part of antioxidant 1010 and 0.1 part of antioxidant 168 in a high-speed mixer for 3 to 5 minutes, and then Melting extrusion and granulation in the twin-screw extruder, the process is: 220-230℃ in the first zone, 230-240℃ in the second zone, 230-240℃ in the third zone, 215-225℃ in the fourth zone; the whole extrusion process The residence time is 1-2 minutes, a...

Embodiment 2

[0048] Preparation of hydrophobic odor-absorbing masterbatch: Weigh 60% of ABS and 40% of hydrophobic odor-absorbing agent, dry mix them in a high-speed mixer for 3-5 minutes, then melt-extrude them in a twin-screw extruder, and granulate. Aluminum foil is vacuum sealed and ready for use. The extrusion process is as follows: zone 1 200-210°C, zone 2 210-220°C, zone 3 210-220°C, zone 4 205-215°C; the residence time of the entire extrusion process is 1 -2 minutes, the pressure is 12-18MPa.

[0049] Preparation of low-odor ABS resin compound: dry-mix 100 parts of ABS, 3 parts of hydrophobic odor-absorbing masterbatch, 0.2 part of antioxidant 1010 and 0.1 part of antioxidant 168 in a high-speed mixer for 3 to 5 minutes, and then Melting extrusion and granulation in the twin-screw extruder, the process is: 220-230℃ in the first zone, 230-240℃ in the second zone, 230-240℃ in the third zone, 215-225℃ in the fourth zone; the whole extrusion process The residence time is 1-2 minutes, ...

Embodiment 3

[0051] Preparation of hydrophobic odor-absorbing masterbatch: Weigh 60% of ABS and 40% of hydrophobic odor-absorbing agent, dry mix them in a high-speed mixer for 3-5 minutes, then melt-extrude them in a twin-screw extruder, and granulate. Aluminum foil is vacuum sealed and ready for use. The extrusion process is as follows: zone 1 200-210°C, zone 2 210-220°C, zone 3 210-220°C, zone 4 205-215°C; the residence time of the entire extrusion process is 1 -2 minutes, the pressure is 12-18MPa.

[0052] Preparation of low-odor ABS resin compound: dry-mix 100 parts of ABS, 5 parts of hydrophobic odor-absorbing masterbatches, 0.2 parts of antioxidant 1010 and 0.1% of antioxidant 168 in a high-speed mixer for 3 to 5 minutes, and then Melting extrusion and granulation in the twin-screw extruder, the process is: 220-230℃ in the first zone, 230-240℃ in the second zone, 230-240℃ in the third zone, 215-225℃ in the fourth zone; the whole extrusion process The residence time is 1-2 minutes, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com