Low-odor, low-volatilization and high-wear-resistance polyethylene glycol terephthalate composition and preparation method thereof

A kind of polyethylene terephthalate, polybutylene terephthalate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

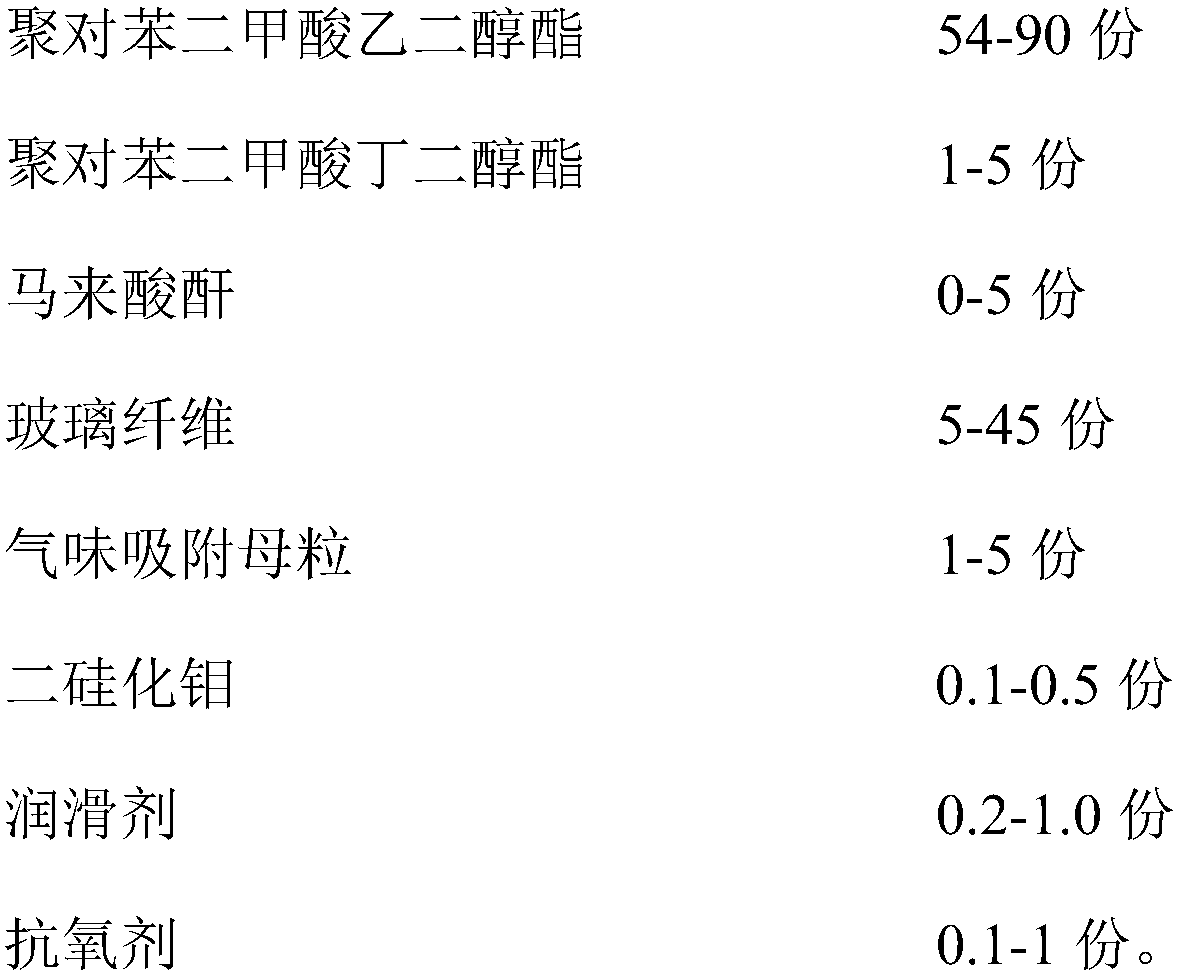

Method used

Image

Examples

preparation example Construction

[0032] Preparation of odor adsorption masterbatch: 100 parts of high-density polyethylene, 5 parts of hydrophobic diatomaceous earth, 10 parts of hydrophobic activated carbon, 5 parts of needle-shaped zeolite molecular sieve, 10 parts of zinc ricinoleate, 5 parts of nano-silica, hard 1 part of calcium fatty acid and 5 parts of melamine were uniformly mixed, and then extruded and granulated in a twin-screw extruder to obtain odor-absorbing masterbatches.

[0033] The crystallinity of high-density polyethylene is 85%, and the number average molecular weight is 250,000.

[0034] The melt index of polyethylene terephthalate is 25-28g / 10min; the melt index of polybutylene terephthalate is 28-30g / 10min.

Embodiment 1

[0036] 70 parts of polyethylene terephthalate, 1 part of polybutylene terephthalate, 1 part of maleic anhydride, 3 parts of odor-absorbing masterbatches, 0.5 parts of molybdenum disilicide, 1 part of silicone powder, Add 0.5 parts of antioxidant 1010 and 0.5 parts of antioxidant 168 into a high-speed mixer, stir at a high speed, mix until uniform, then add to a twin-screw extruder, and mix 30 parts of polypyromellitic imide modified glass fibers from The glass fiber is added into the mouth, melted and extruded, and then granulated to obtain a polyethylene terephthalate composition with low odor, low emission and high wear resistance.

[0037] The temperature of the first zone of the twin-screw extruder is 180°C, the temperature of the second zone is 180°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 210°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zone is 245°C; The rotational speed of the twin-screw main...

Embodiment 2

[0039] 54 parts of polyethylene terephthalate, 2 parts of polybutylene terephthalate, 2 parts of maleic anhydride, 1 part of odor absorption masterbatch, 0.2 part of molybdenum disilicide, 0.2 part of paraffin, 0.1 part Antioxidant 1010 and 0.1 part of antioxidant 168 were added to a high-speed mixer, stirred at a high speed, mixed until uniform, then added to a twin-screw extruder, and 30 parts of polypyromellitic imide modified glass fibers were made from glass fiber Orally added, melted and extruded, then granulated to obtain a polyethylene terephthalate composition with low odor, low emission and high wear resistance.

[0040] The temperature of the first zone of the twin-screw extruder is 190°C, the temperature of the second zone is 190°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 300°C, and the temperature of the sixth zone is 300°C; The rotational speed of the twin-screw main engine is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com